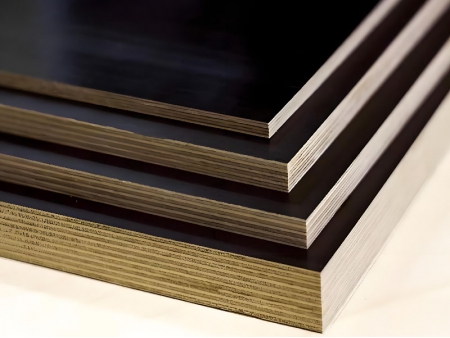

Poplar/Combi/Hardwood Core Film Faced Plywood

At Sindo, we are a professional wood panel supplier, offering a variety of film-faced plywood options to meet different project requirements. These include poplar core, combi core, and hardwood core film-faced plywood, each designed to meet specific construction needs.

This film faced plywood uses freshly rotary-cut wood veneer as raw material, with ordinary melamine-impregnated film paper adhered to the surface and bottom. It is primarily used for construction formworks and can be reused 8 to 25 times, depending on the materials used.

-

- Core: Poplar

- Film: Phenolic Dynea film, brown film, black film, red film (Film can be imprinted with requested logo)

- Size: 1200×2400mm, 1220×2440mm(4'×8'), 610×2440mm(2'×8'), 1250×2500mm, 915×1830mm(3'×6') or as per your requirement

- Thickness: 9/12/15/17/18/21/24/27/30mm or upon request

- Density: 530kg/m³

- Edge: Sealed with water proof paint and paint color can be upon request

- Glue: WBP-PHENOLIC, WBP-MELAMINE, MR

- Hot: Press one time / two times / three times press

- Formaldehyde: Emission E0, E1, E2

Made with poplar as the core material, this plywood takes advantage of China’s abundant poplar resources, making it an affordable and cost-effective option. It provides reliable performance and meets basic construction needs, making it ideal for large-scale projects where value is key.

-

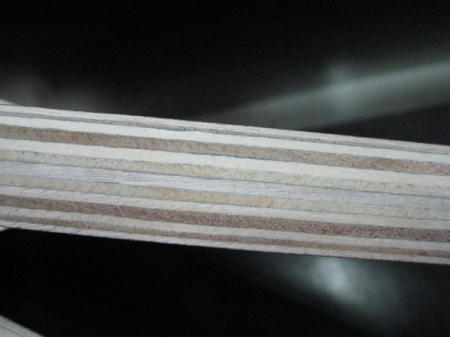

- Core: Combined (poplar mixed eucalyptus or birch)

- Film: Phenolic Dynea film, brown film, black film, red film (Film can be imprinted with requested logo)

- Size: 1200×2400mm, 1220×2440mm(4'×8'), 610×2440mm(2'×8'), 1250×2500mm, 915×1830mm(3'×6') or as per your requirement

- Thickness: 9/12/15/17/18/21/24/27/30mm or upon request

- Density: 540-550kg/m³

- Edge: Sealed with water proof paint and paint color can be upon request

- Glue: WBP-PHENOLIC, WBP-MELAMINE, MR

- Hot: Press one time / two times / three times press

- Formaldehyde: Emission E0, E1, E2

This type combines poplar and hardwood at its core, resulting in a stronger, more durable plywood. The inclusion of hardwood improves strength and lifespan, offering a good balance between cost and performance for projects that require increased durability.

-

- Core: Chinese Hardwood (eucalyptus, birch)

- Film: Phenolic Dynea film, brown film, black film, red film (Film can be imprinted with requested logo)

- Size: 1200×2400mm, 1220×2440mm(4'×8'), 610×2440mm(2'×8'), 1250×2500mm, 915×1830mm(3'×6') or as per your requirement

- Thickness: 9/12/15/17/18/21/24/27/30mm or upon request

- Density: 560-650kg/m³

- Edge: Sealed with water proof paint and paint color can be upon request

- Glue: WBP-PHENOLIC, WBP-MELAMINE, MR

- Hot: Press one time / two times / three times press

- Formaldehyde: Emission E0, E1, E2

Made entirely from hardwood sourced near our production facilities, this plywood offers high density and superior strength. Depending on customer needs, we can also incorporate eucalyptus or birch to further enhance density. This type is ideal for projects requiring heavy-duty performance and frequent reuse, ensuring long-lasting reliability.

- Veneer Cleaning

- Veneer Drying

- Gluing and Grouping

- Prepressing

- Hot Pressing

- Sanding

- Film Facing

- Sorting

- Packaging

Talk or write to our team to find the right product for your application, and discover how they can help you achieve your construction goals.