Single Screw

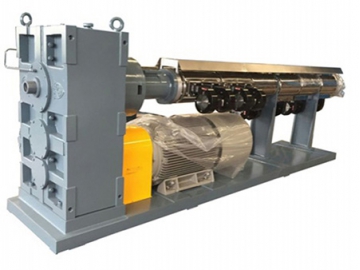

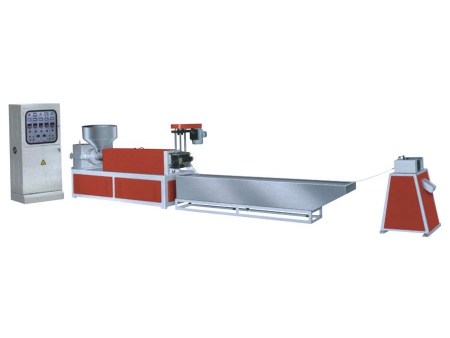

A better screw with a high abrasion-resistance ensures there is a higher product quality and a longer service life for your single screw extruder. We are dedicated to the research and development of a variety of custom made screws using abrasion resistant materials, including multiple thread screws, barrier screws, vented screws etc.

Design optimization of extrusion barrels and screws boosts the yield and reduces energy consumption for polymeric materials. Images shown below show our screws and their suitability for a variety of plastics.

Our customized service gives our customers opportunities to improve extrusion barrels and extrusion screws. The basic parameters like plastic materials, extruded finished products, yield, motor power, maximum screw speed and original screw models are required for our manufacture.

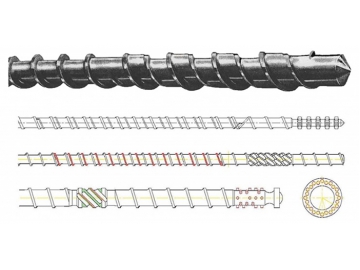

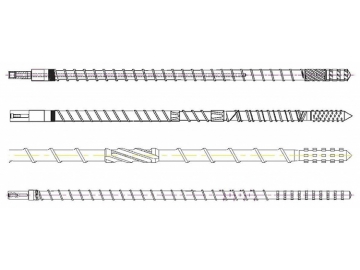

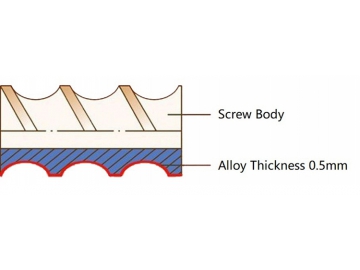

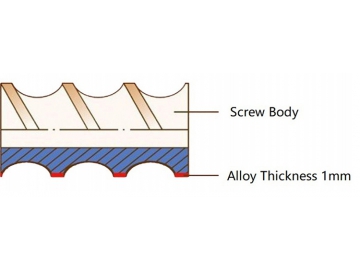

With the use of a specific alloy formed on the surface of the screw, Omega’s bimetallic screws are corrosion resistant, abrasion resistant, and feature a long service life.

Flight covered by alloy layers

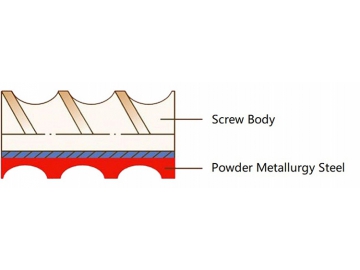

Flight covered by alloy layers A screw body with a driving function is made using a strong steel, and the flight is made using a powdered metallurgy steel.

A screw body with a driving function is made using a strong steel, and the flight is made using a powdered metallurgy steel.

Among the 3 different types of bimetallic screws, the flight covered in an alloy layer is the most popular due to its low cost. This bimetallic screw has a basic body metal which can be welded and nitrided. The nitrogenization ensures a high hardness for the faces even without the protection of the alloy layer.

- 4Cr5MoSiV1(Nitriding Steel)

- 38CrMoAl (Nitrding steel)

- Cr12MoV (Vacuum hardened )

- Cr12Mo1V (Vacuum hardened)

- W18Cr4V (Vacuum hardened)

- W6Mo5Cr4V2 (Vacuum hardened)

- W6Mo5Cr4V3 (Vacuum hardened)

- W2Mo9Cr4V2 (Vacuum hardened)

- 00Cr17Ni14Mo2

- 0Cr17Ni4Cu4Nb

- 00Cr25Ni20Mo3Mn2N(F103, 113)

- 9Cr18MoV

- Fe-based Ω101 Alloy layer

- Ni-based Ω301 Alloy layer

- SiC Composite Ceramics Oval Liner