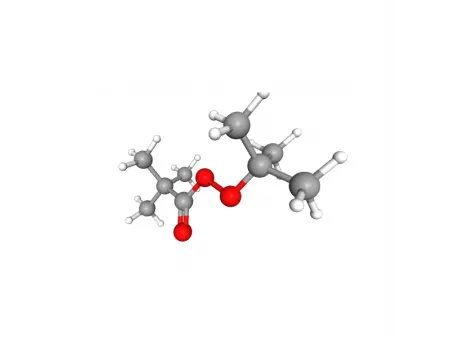

tert-Butyl peroxypivalate (TBPV)

- Chemical Family Organic Peroxide

- Molecular Formula C₉H₁₈O₃

- Molecular Weight 174.2

- EINECS 213-147-2

- UN No. 3113

- Transport Hazard Class 5.2

- (organic peroxide, Type C, liquid, subject to temperature control in transport, forbidden for rail and air transport)

Half-Life Period

- 0.1 hour 94℃

- 1 hour 75℃

- 10 hours 57℃

- Theoretical active oxygen content: 9.18%

- Purity: 75.0%

- Self-accelerating decomposition temperature (SADT): 20℃

- Hazardous temperature (Tem): 10℃

- Temperature control (Tc) : 0℃

- Storage temperature (Ts min/Ts max): -17/-5℃

- Activation energy : 123.59kJ/mol

- Freezing point: <-17

- Appearance: colorless, clear, oily liquid. It can be diluted using solvents such as isododecane or odorless mineral oil (OMS), along with various other solvent options based on customer requirements.

- Viscosity : 2.1mPa.s (-10℃)

- Solubility: Insoluble in water, soluble in most organic solvents

- Chromaticity: 20APHA

- TBHP content: 1000mg/kg max

- Inorganic/organic hydrolyzable chloride: 150mg/kg max

- Major decomposition products: tert-butyl alcohol, isobutyl ketone, isobutane, carbon dioxide

- TBPV is a highly efficient initiator for the polymerization of ethylene, used in high-pressure tubular and stirred reactor processes.

- It functions as an effective initiator in the suspension polymerization of vinyl chloride (PVC), particularly at temperatures between 50-70°C.

- Also used as an initiator in the suspension polymerization of acrylates and methacrylates, as well as in non-aqueous dispersions for coating production.

- Additionally, TBPV is an important initiator for EVA (ethylene-vinyl acetate) polymerization.

- It acts as a curing agent for unsaturated polyester resins at medium temperatures, typically between 80-100°C, making it suitable for hot press molding processes.

- When added to oils, TBPV significantly enhances their quality.

-

Packaging

The standard packaging is a 20 kg polyethylene drum. Customized packaging is available upon request to suit specific customer needs.

-

Validity

When stored and transported according to the manufacturer’s recommendations, the product quality is guaranteed for three months.

-

Safe Handling

Store in a cool, well-ventilated area, with temperatures not exceeding -15°C.

Keep away from open flames and heat sources. Store separately from acids, reducing agents, flammable substances, and combustibles.

Use explosion-proof lighting and ventilation systems in storage areas, with switches located outdoors.

Handle with care to prevent damage to packaging or containers, avoiding impact and vibrations. Proper personal protective equipment should be worn during handling and repackaging operations.

Refer to the product’s Material Safety Data Sheet (MSDS) for detailed safety guidelines.