High Efficiency Compound Crusher

Compound Crushing Machine, Stone Crushing Plant, Rock Crushing Machine, Ore Crushing Machine

Features of the compound crusher

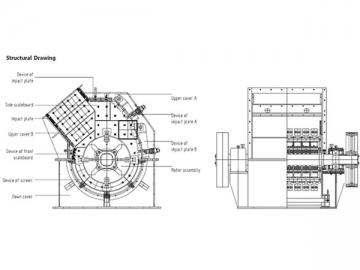

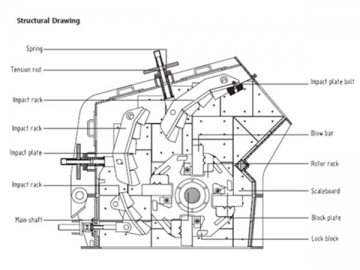

1. Unique design & convenient maintenance

For this compound crusher, the back cover of the upper body can be opened manually or hydraulically, making it easy to replace or repair the spare parts.

2. Adjustable granularity & high efficiency

With the flexible adjustment mechanism of the crushing machine, the granularity of the crushed materials is effectively controlled. About 1/3 equipment investment and 1/2 energy consumption will be saved for a cement raw meal production line if a compound crushing machine is adopted.

3. Wide application

GXP series compound crusher is designed to deal with materials whose compressive strength is no more than 200MPa. The allowable feeding granularity ranges from 450mm to 1000mm, and the average discharging granularity is smaller than 5-8mm.

How does it work

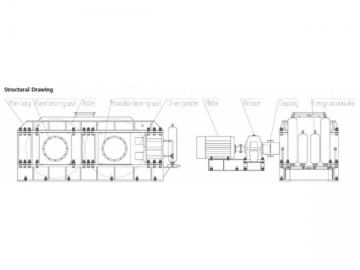

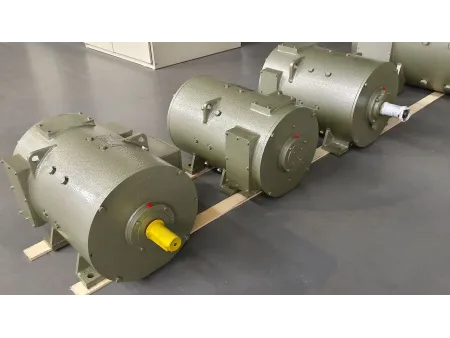

The core part of the compound crusher is the rotor, which is comprised of shaft, disc, pin shaft, and hammer. The rotor will rotate in a high speed in the crushing chamber under the drive of the motor. Under the effect of the rotor, the fed materials will be impacted, cut, grinded and crushed. We have set a perforated plate under the rotor to let those crushed particles pass. The large particles whose granularity have not reached the standards will be retained and continue to be crushed until they are able to be discharged from the rock crushing machine.

Applications of the compound crusher

This series of compound crusher is widely used for crushing cement raw meal, cement clinker, coal, dolomite, flint, lead-zinc, serpentine, blast furnace slag, coal gangue, and phosphate rock, etc.

| Model | Max feeding granularity (mm) | Average discharging granularity (mm) | Production capacity (t/h) | Motor power (t) | Weight (t) | Dimension (mm) |

| GXF-40 | 450 | 3-5 | 35-45 | 75 | 12 | 2231×1940×2168 |

| GXF-60 | 500 | 5-8 | 55-65 | 90 | 18 | 2231×1940×2168 |

| GXF-80 | 500 | 5-8 | 75-85 | 132 | 21 | 2550×2630×2670 |

| GXF-100 | 600 | 5-8 | 90-110 | 185 | 25 | 2550×3120×2670 |

| GXF-120 | 600 | 5-8 | 110-130 | 200 | 28 | 2550×3390×2670 |

| GXF-160 | 700 | 5-8 | 140-180 | 250 | 32.5 | 2793×3140×3014 |

| GXF-200 | 700 | 5-8 | 190-220 | 280 | 38.5 | 2793×3410×3014 |

| GXF-300 | 1000 | 8-12 | 280-340 | 450 | 55 | 3670×3850×4135 |

| GXF-400 | 1000 | 8-12 | 380-420 | 560 | 65 | 3670×4180×4135 |

| GXF-500 | 1000 | 8-12 | 460-520 | 710 | 75 | 3670×4500×4135 |