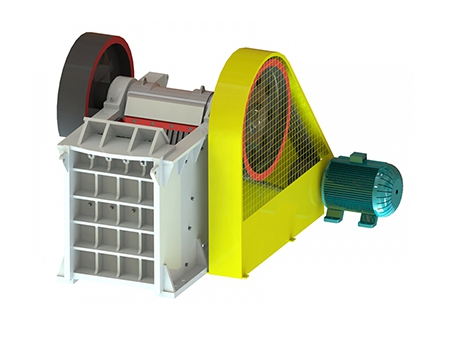

Double Roll Crusher

Roll Crusher, Stone Crushing Machine, Rock Crusher, Ore Crusher, Cement Crusher, Coal Crusher

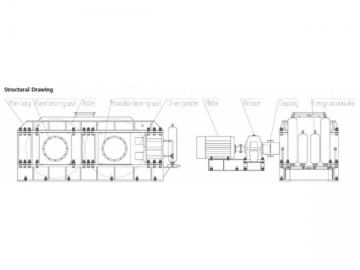

2PG series crushing machine takes advantages of traditional roll crusher and rolling machine. With the integration of mechanical, electrical, and hydraulic factors, the crushing efficiency and stability of the crusher is largely improved. Its hydraulic system works stably.

Main attributes of the roll crusher

1. Within the 2 rollers, we set a dustproof plate for good sealing effect and to reduce the dust pollution. The noise of the stone crusher is rather low.

2. It doesn' t need to replace the grinding rolls for the whole machine life since we have specially modified the rolls.

3. Replaceable wear-resistant plates are alternative for the grinding rolls. The linings are made from advanced wear-resistant materials and can be used continuously for over 1 year. When there is a necessity of replacement, users only need to move the cover of the crushing equipment.

How does it work

The crushing structure of the double roll crusher is consisted of a pair of horizontally mounted cylindrical rollers which are parallel to each other. When the 2 rolls rotate against each other, the materials to be crushed will fall on the rolls and be rolled into the gap between the 2 rollers. Then the materials are under the compression of the rolls. They will be crushed into particles when the extrusion press exceeds the synergy between the lattice, and then be discharged by the rotating rolls.

Applications of the double roll crusher

2PG series double roll crusher is used for crushing materials with medium hardness such as rocks, ore, coal, slag, mineral slag, cement clinker, and fireproof materials in metallurgy, coal, mineral processing, artificial sand, construction waste recycling, building materials, chemicals and many other industries.

| Model | Roller diameter (mm) | Production capacity (t/h) | Max feeding size (mm) | Closed-side setting (mm) (f=8) | Dimension(mm) | Reducer | Motor | Weight (t) |

| Φ600×400 | Φ600 | ~12 | <20 | <3mm,75% | 1690×1940×850 | ZLY180-20-Ⅰ×2 | Y180L-6 15KW×2 | 4.8 |

| Φ800×600 | Φ800 | ~25 | <25 | <3mm,72% | 2250×3269×1060 | ZLY200-20-Ⅰ×2 | Y200L2-6 22KW×2 | 7.5 |

| Φ1000×700 | Φ1000 | ~40 | <30 | <3mm,70% | 2894×3773×1285 | ZLY224-20-Ⅰ×2 | Y225M-6 30KW×2 | 14.8 |

| Φ1200×700 | Φ1200 | ~70 | <40 | <3mm,70% | 3444×3537×1448 | ZLY280-20-Ⅰ ZLY280-20-Ⅵ | Y280M-6 55KW×2 | 21.5 |

| Φ1200×800 | Φ1200 | ~70 | <40 | <5mm,65% | 3444×3637×1448 | ZLY280-20-Ⅰ ZLY280-20-Ⅵ | Y280M-6 55KW×2 | 24.5 |

| Φ1500×700 | Φ1500 | ~150 | <50 | <3mm,72% | 4133×3970×1760 | ZLY355-20-Ⅰ ZLY355-20-Ⅵ | Y315L2-8 110KW×2 | 32.5 |

| Φ1500×800 | Φ1500 | ~150 | <50 | <5mm,70% | 4133×4070×1760 | ZLY355-20-Ⅰ ZLY355-20-Ⅵ | Y355M2-8 110KW×2 | 35 |

| Φ1800×800 | Φ1800 | ~210 | <60 | <3mm,75% | 4860×4208×2050 | ZLY450-20-Ⅰ ZLY450-20-Ⅵ | Y355M2-8 160KW×2 | 49 |

| Φ2000×1000 | Φ2000 | ~350 | <70 | <5mm,72% | 5100×4950×2550 | ZSY560-31.5-Ⅰ ZSY560-31.5-Ⅵ | Y355L1-6 220KW×2 | 90 |