Single Cylinder Carding Machine

Request a Quote

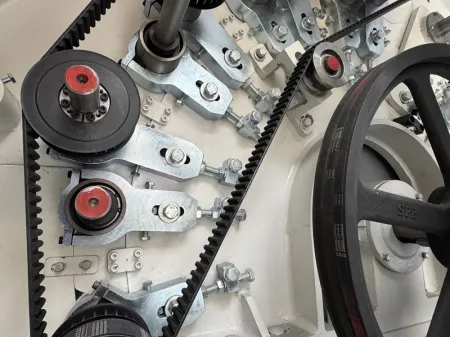

Carding system for converting fiber batt into fiber web

In the nonwoven manufacturing process, the single cylinder carding machine plays a crucial role in transforming the fiber batt into fiber web. The fiber raw material undergoes processing in the carding machine, gradually breaking down from a clustered state into individual fibers, which are separated in different carding zones on the machine. Ultimately, these individual fibers are collected to form a complete fiber web, which is then used for further processing and manufacturing of nonwoven fabric products.

Specifications

| Working width | 1550mm | 1850mm | 2000mm | 2300mm | 2500mm |

| Diameter of cylinder | 1230mm | ||||

| Diameter of doffer | 492mm | ||||

| Output speed | ≤50m/min | ||||

| Capacity | ≤400kg/h (varying with fiber specification) | ||||

Functions

- Single cylinder carding machine is applicable to various nonwoven production processes, like needle punching, thermal bonding, chemical bonding, etc.

- This carding system can be used to process a variety of fibers, such as polyester fibers, viscose fibers, nylon fibers, polypropylene fibers, jute fibers, glass fibers, carbon fibers, etc.

Features

- The single cylinder carding machine is equipped with variable frequency control for speed adjustment, making it suitable for carding various fibers and producing different products.

- Separated transmission ensures flexible and accurate operation.

- Exquisite mechanical craftsmanship limits the radial runout to within 0.02 mm, resulting in higher uniformity of the fiber web.

- The circulating suction device and enclosed housing help in reducing noise and fiber flocks.