Tunnel Oven

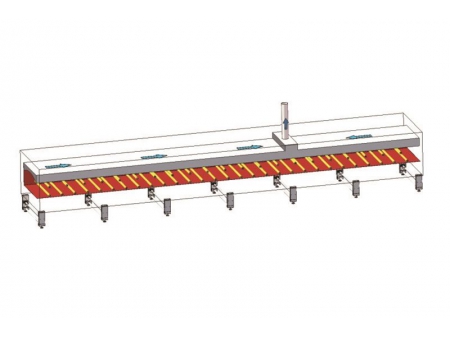

The tunnel oven developed by Evergrowing Machinery, a Chinese professional food machinery manufacturer, is a very important part in the biscuit production line. This food baking equipment is available in two types, namely gas oven and electric oven. Generally, it is divided into four functional areas covering dough expanding, shaping, dehydrating and coloring.

Our tunnel oven, known as a biscuit oven is divided into a hybrid gas oven and heated air circulation electric oven.

- Hybrid gas oven

- Touch screen

- Gas pipe proportion motor

- Gas mixing value

- Conveying into the oven

- Biscuits in oven chamber

The hybrid gas oven is a combination of a direct-fired gas oven and a hot air convection oven. This food machinery integrates the temperature and humidity needed for biscuits and boasts a unique oven chamber design and installation methods, thus ensuring low energy consumption while enhancing thermal insulation performance. This tunnel oven is designed with a PLC controller, a variable frequency motor and a pneumatic baking band auto off tracking device.

Technical Parameters of Hybrid Gas Oven

| Oven Length | 20-90m |

| Inner wall treatment | Spraying aluminum powder and high-temperature resistant silicone paint |

| Diameter of big roller | φ 1000mm |

| Combustion system (1.45 million kilocalorie) | Direct gas combustion in zone 1 and 2; hot-wind convection in zone 3 and 4. Italy Baltur self-control combustion machines |

| Fuel gas source | Natural gas, LPG, pipelined gas |

| Thermal insulation material | 80kg/m3 rock wool |

| Operation method | Touch screen |

| Control type | PLC |

| Power supply | 3-380V, AC |

| PLC brand | French Schneider |

| Pipeline solenoid valve brand | USA Honeywell |

| Fire pipe solenoid valve brand | Germany Burkert |

| Zero pressure valves brand | Japan Aichi |

| Control motor brand | USA Honeywell |

- Electric oven

- Touch screen - electric oven

- Steel oven band

- Biscuits in electric oven chamber

- Cookies out of oven

- Cookies conveyed into oven

- Discharging device

The tunnel oven employs circulating heated air to heat the oven body. It features PLC control and variable frequency speed control, and comes with an automatic air driven off tracking device for the control of the position of the baking belt. In addition, due to the unique design of the oven chamber as well as air feed and exhaust device, the electric oven can precisely control the temperature and humidity for baking, and lower considerable energy consumption while ensuring uniform color of the biscuits. Therefore, this food oven has become a piece of indispensable equipment in biscuit production lines.