Doctor Blades & Blade Holders for Paper Machine

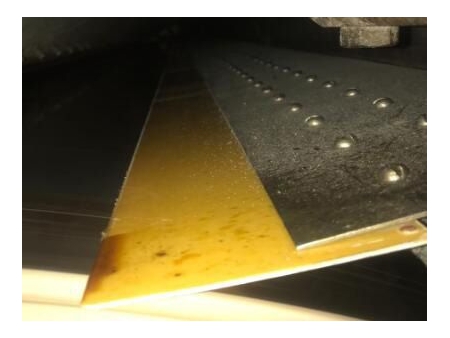

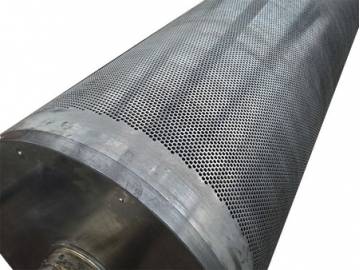

Doctor blade is widely applied in paper making machines and corrugated cardboard machines. It is mainly configured with blade body, blade holder, moving and fixed devices. The main applications of doctor blades are shedding the sheet at sheet breaks or sheet threading and removing excessive water and contaminants from the doctored roll surface. And the keys to achieving an optimal doctoring process are state-of-the-art blade materials, modern roll covers, suitable doctoring equipment and optimal doctoring parameters. So as to ensure their safe and efficient operation, regular cleaning and quality testing must be considered. The reason is that the performance and reliability of components used for paper machines, to a large extent, are influenced by a variety of factors. More importantly, with the improvement in width and speed of the paper machine, doctor blades play an increasingly vital role in cleaning the roll surface during the operation of the paper machine.

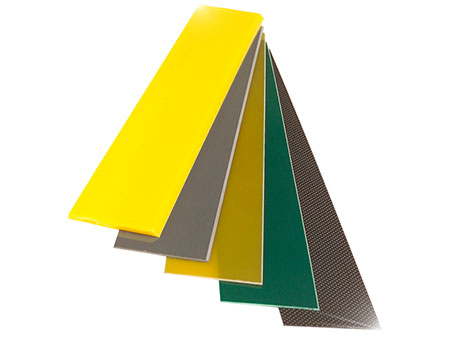

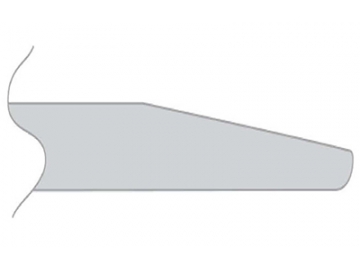

With regard to various selections of suitable materials of doctor blades for your particular application, six basic types of doctor blades are as follows:

- Carbon fiber doctor blades, with options of full carbon fiber, 60% carbon fiber, 40% carbon fiber, 20% carbon fiber;

- Glass fiber doctor blades;

- High polymer polyethylene doctor blades;

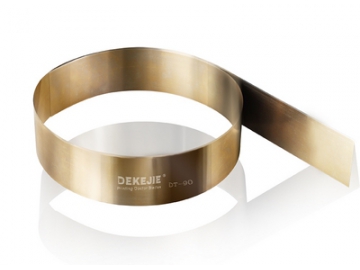

- Phosphor bronze doctor blades;

- Corrugated doctor blades;

- Stainless steel doctor blades;

| Material | Thickness | Width | High-temperature resistance |

| Carton fiber blade 20%, 40%, 60%, 100% | 1.5mm | 50mm, 76mm, 100mm | 185℃ |

| 1.9mm | 50mm, 76mm, 100mm | ||

| 3.0mm | 50mm, 76mm, 100mm | ||

| EPO-glass fiber blade | 1.5mm | 50mm, 76mm, 100mm | 185℃ |

| 1.9mm | 50mm, 76mm, 100mm | ||

| 3.0mm | 50mm, 76mm, 100mm | ||

| HDPE blade | 3.0mm | 50mm, 76mm, 100mm | 80℃ |

| 5.0mm | 50mm, 76mm, 100mm | ||

| 6.35mm | 50mm, 76mm, 100mm | ||

| Creping blade blue steel | 0.381mm - 3.50mm | 50mm-160mm | Hardness 45-52 HRC |

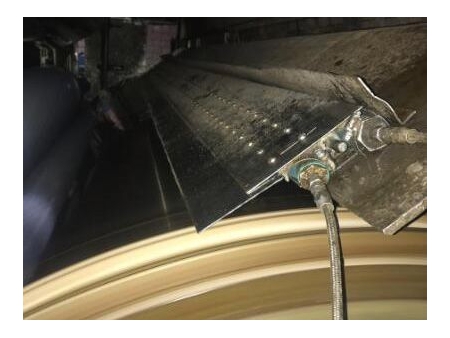

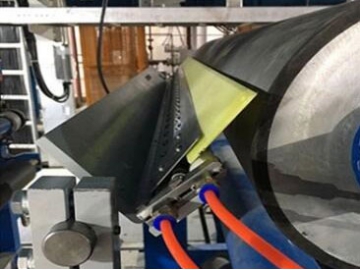

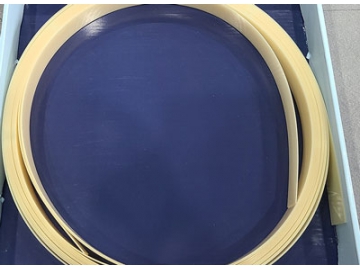

Huatao K35 self-aligning doctor blade holders are specially designed for press rolls using blades. The compact design of our doctor holders combines a composite holder and a composite top plate in an optimal way, which results in excellent profiling properties, allowing the doctor blade to conform to the roll surface being doctored. Furthermore, we produce a range of gravity loaded doctor holders, ranging from traditional holder types to modern carbon fiber holders, which are widely used in the contemporary papermaking industry. In order to achieve accurate alignment under applied pressure, high-quality materials and components must be manufactured to precise tolerances.

Huatao pneumatic doctor blade holder, also called DST blade holder, is suitable for various rolls and cylinders in paper making machine to provide even loading for the doctor blade, enabling the doctor beam to be locked in a solid position. The advantage of DST blade holder is that because it is not manually controlled, ensuring that it can apply equal load to both ends of the doctor beam simultaneously. So, effective rolls cleaning and longer service life can be achieved in this manner. Additionally, the pneumatically loaded blade holder is commonly applicable in critical sheet removal and cleaning applications.