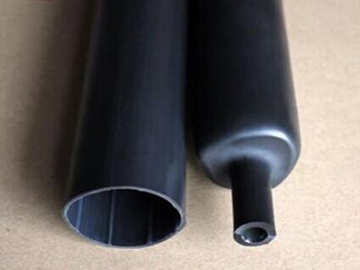

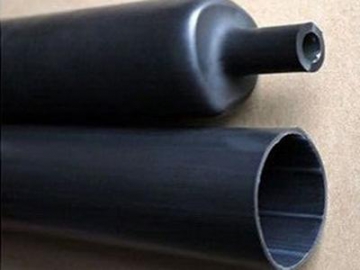

Flame Retardant Dual Wall Heat Shrink Tubing (Item HAFR140, Heavy Wall Adhesive Lined Tubing, Black, 3:1 Shrink Ratio)

Request a Quote

The flame retardant dual wall heat shrink tubing consists of two layers which is retardant EVA and hot-melt adhesive. The outer one is EVA and the inner one is hot-melt adhesive. Flame retardant dual wall heat shrink tubing has excellent advantages in insulation, sealing, waterproof, mechanical protection, moisture prevention and impact resistance and can also resist ultraviolet rays.

Product features

| The lowest temperature of beginning shrinking | 70℃ |

| The lowest temperature of ending shrinking | 125℃ |

| Operating temperature | -45℃~125℃ |

| Heat shrinking ratio | 3:1 |

| Environmental standard | RoHS |

| Flame retardant type | outer layer true |

| Major material | EVA |

| Standard color | black (other colors can be ordered) |

| Specification | Inner diameter before shrinking (mm) | Size after shrinking (mm) | Package standard | |||||

| Inner diameter Minimum | Inner diameter maximum | The outer layer wall thickness | Adhesive layer thickness | Average total wall thickness | Meter/piece | |||

| 9/3 | 9.0 | 3.0 | 2.0±0.20 | 0.35±0.10 | 2.30±0.25 | 1.22 | ||

| 13 /4 | 13.0 | 4.0 | 2.4±0.20 | 0.35±0.10 | 2.75±0.25 | 1.22 | ||

| 20 /6 | 20.0 | 6.0 | 2.5±0.20 | 0.40±0.10 | 2.90±0.25 | 1.22 | ||

| 28 /9 | 28.0 | 9.0 | 2.5±0.20 | 0.40±0.10 | 2.90±0.25 | 1.22 | ||

| 33 /10.2 | 33.0 | 10.2 | 3.2±0.20 | 0.40±0.10 | 3.60±0.25 | 1.22 | ||

| 38.1/12 | 38.1 | 12.0 | 3.4±0.25 | 0.60±0.15 | 4.00±0.30 | 1.22 | ||

| 43.2/12.7 | 43.2 | 12.7 | 3.8±0.30 | 0.70±0.20 | 5.00±0.35 | 1.22 | ||

| 55 /16 | 55.0 | 16.0 | 4.0±0.30 | 0.70±0.20 | 5.00±0.35 | 1.22 | ||

| 75/22 | 75.0 | 22.0 | 4.3±0.30 | 0.70±0.20 | 5.00±0.35 | 1.22 | ||

| 85/25 | 85.0 | 25.0 | 4.3±0.30 | 0.70±0.20 | 5.00±0.35 | 1.22 | ||

| 105/30 | 105 | 30.0 | 4.3±0.30 | 0.80±0.25 | 5.10±0.35 | 1.22 | ||

| 120/39 | 120 | 39.0 | 4.3±0.30 | 0.80±0.25 | 5.10±0.35 | 1.22 | ||

| 140/42 | 140 | 42.0 | 4.3±0.30 | 0.80±0.25 | 5.10±0.35 | 1.22 | ||

| Property | Index | Test method |

| Tensile strength | ≥12MPa | ASTM D 2671 |

| Breaking elongation | ≥300% | ASTM D 2671 |

| Tensile strength after heat aging | ≥8.4MPa | 158℃×168h |

| Breaking elongation after heat aging | ≥100% | 158℃×168h |

| The axial changing ratio | -8%~+8% | ASTM D 2671 |

| Flame retardant property | Self-extinguish within 30s | SAE-AMS-DTL-23053/4 |

| Disruptive strength | ≥15kV/mm | IEC 60243 |

| Volume resistivity | ≥1014Ω=cm | IEC 60093 |

Related products

Flame Retardant Dual Wall Heat Shrink Tubing (Item AFR140, Adhesive Lined Tubing, Black, 3:1 Shrink Ratio)

Single Wall Flame Retardant Heat Shrink Tubing (Item HFR140, Black Heavy Wall Tubing, 3:1 Shrink Ratio)

Send Message

Other Products

Most Recent

More

Other Products

Videos