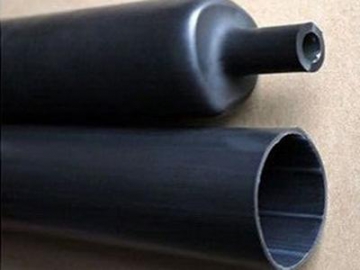

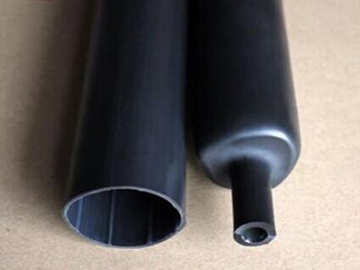

3:1 Semi-Rigid Dual Wall Heat Shrink Tubing (Item HASR180, Black, Adhesive Lined Heavy Wall Tubing)

Request a Quote

The 3:1 Semi-rigid dual wall heat shrink tubing is made of semi-rigid EVA and hot-melt adhesive. The outer EVA material is hard and resistant to abrasion. And when heated, the inner layer hot-melt adhesive will melt and stick to the surface of the wire and realizes waterproof and sealing.

So the heat shrink tubing has three major specialties, insulation, sealing and abrasion resistance. It can be widely used for insulation of wires and cables outdoors and indoors, along with corrosion and abrasion resistance for all kinds of pipes.

Product features| The lowest temperature of beginning shrinking | 70℃ |

| The lowest temperature of ending shrinking | 125℃ |

| Operating temperature | -45℃~125℃ |

| Heat shrinking ratio | 3:1 |

| Environmental standard | RoHS |

| Major material | Semi-rigid EVA |

| Standard color | Black (other colors can be ordered) |

| Specification | Inner diameter before shrinking (mm) | Size after shrinking (mm) | Package standard | |||||

| Inner diameter Minimum | Inner diameter maximum | The outer layer wall thickness | Adhesive layer thickness | Average total wall thickness | Meter/piece | |||

| Φ8/2 | 8 | 2 | 1.80±0.20 | 0.55±0.10 | 2.35±0.25 | 1.22 | ||

| Φ9/3 | 9 | 3 | 2.00±0.20 | 0.55±0.10 | 2.55±0.25 | 1.22 | ||

| Φ13/4 | 13 | 4 | 2.30±0.20 | 0.55±0.10 | 2.85±0.25 | 1.22 | ||

| Φ16.0/5.0 | 16 | 5 | 2.30±0.20 | 0.60±0.10 | 2.90±0.25 | 1.22 | ||

| Φ22.0/6.0 | 22 | 6 | 2.50±0.20 | 0.60±0.10 | 3.10±0.30 | 1.22 | ||

| Φ28.0/6.0 | 28 | 6 | 2.70±0.20 | 0.70±0.20 | 3.40±0.35 | 1.22 | ||

| Φ33.0/8.0 | 33 | 8 | 2.80±0.25 | 0.80±0.15 | 3.60±0.35 | 1.22 | ||

| Φ38.1/12.0 | 38.1 | 12 | 3.10±0.25 | 0.80±0.15 | 3.90±0.35 | 1.22 | ||

| Φ43.2/12.0 | 43.2 | 12 | 3.50±0.30 | 0.80±0.15 | 4.30±0.40 | 1.22 | ||

| Φ55.0/16.0 | 55 | 16 | 3.60±0.30 | 0.80±0.15 | 4.40±0.40 | 1.22 | ||

| Φ65.0/19.0 | 65 | 19 | 3.60±0.30 | 0.80±0.15 | 4.40±0.40 | 1.22 | ||

| Φ75.0/22.0 | 75 | 22 | 3.60±0.30 | 0.80±0.15 | 4.40±0.40 | 1.22 | ||

| Φ85.0/25.0 | 85 | 25 | 3.60±0.30 | 0.80±0.15 | 4.40±0.40 | 1.22 | ||

| Φ95.0/30.0 | 95 | 30 | 3.60±0.30 | 0.80±0.15 | 4.40±0.40 | 1.22 | ||

| Φ105/30.0 | 105 | 30 | 3.80±0.30 | 0.80±0.15 | 4.60±0.40 | 1.22 | ||

| Φ120/39.0 | 120 | 39 | 3.80±0.30 | 0.80±0.15 | 4.60±0.40 | 1.22 | ||

| Φ130/40.0 | 130 | 40 | 3.80±0.30 | 0.80±0.15 | 4.60±0.40 | 1.22 | ||

| Φ140/42.0 | 140 | 42 | 3.80±0.30 | 0.80±0.15 | 4.60±0.40 | 1.22 | ||

| Φ160/50.0 | 160 | 50 | 3.80±0.30 | 0.80±0.15 | 4.60±0.40 | 1 | ||

| Φ180/60.0 | 180 | 60 | 3.80±0.30 | 0.80±0.15 | 4.60±0.40 | 1 | ||

| Property | Index | Test method |

| Tensile strength | ≥14MPa | ASTM D 2671 |

| Breaking elongation | ≥400% | ASTM D 2671 |

| Tensile strength after heat aging | ≥12MPa | 158℃×168h |

| Breaking elongation after heat aging | ≥300% | 158℃×168h |

| The axial changing ratio | -8%~+8% | ASTM D 2671 |

| Disruptive strength | ≥20kV/mm | IEC 60243 |

| Disruptive strength | ≥1014Ω.cm | IEC 60093 |

| Copper stability | YES | ASTM D 2671 |

| Water absorption ratio | 0.005 | ASTM D 570 |

| Property | Index | Test method |

| Softening point | 95℃±5℃ | ASTM E 28 |

| Water absorption point | 0.005 | ASTM D 570 |

| The minimum peel strength of PE | ≥120N/25mm | ASTM D 1000 |

| The minimum peel strength of AL | ≥80N/25mm | ASTM D 1000 |

Related products

Dual Wall Semi-Rigid Heat Shrink Tubing (Item ASR230, Adhesive Lined Tubing, Black, 3:1 Shrink Ratio)

Send Message

Other Products

Most Recent

More

Other Products

Videos