VCI Film(Plastic Film with High Corrosion Resistance )

Product Overview

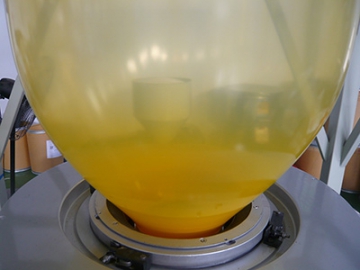

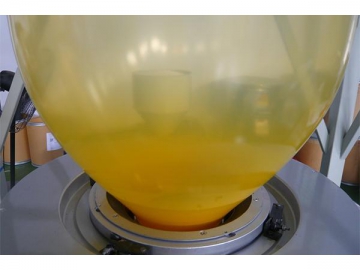

The high-strength VCI plastic film is one of our patented VCI film products. The VCI packaging film starts from plastic resins mixed with specially formulated VCI. Via a process known as extrusion blow molding, the VCI film takes its final shape. High-strength VCI plastic film is economical, eco-friendly packaging material designed for metal parts manufacturers who seek for cheap rust prevention packaging solutions. VCI film works by releasing VCI vapor into the surrounding atmosphere which later condenses onto the metal surface as a corrosion protection barrier between the metal and contaminants in the environment. VCI film keeps water, oxygen, and other corrosive gases from the metal and cut it from any contact with corrosive sources.

Features of High-Strength VCI Plastic Film

1. Specially formulated volatile corrosion inhibitor spread through every inch of enclosed space formed within the package.

2. Exceptional tear strength makes the VCI film ideal for wrapping steel coils, engines, and other bulky equipment.

3. Transparent characteristics allow metal components manufacturers to see through the VCI packaging easily to check the conditions of metal parts enclosed within.

4. High-stretch VCI packaging film is tough, easy to use, and can be sealed through hot air welding.

5. Users can easily convert the film into bags, tubing, or covers for use.

6. Packaging metal pieces with VCI film is easy and does not generate any pollution around the site. VCI film package is easy to open and metal enclosed within is ready for immediate use upon removing from the package without the need of rework or inspection.

7. VCI plastic film is totally recyclable.

Applications for High-Strength VCI Packaging Film

Protect cold-rolled steel sheets including carbon steel sheets and color-coated sheets with VCI film. Or use VCI packaging to wrap engines and large, bulky equipment.

VCI Film Products

VCI film products are blow molded in one pass and can be easily converted into flat bags, gusset bags, zipper bags, tubing, sheeting, or other custom shapes and sizes. This high-strength packaging film is totally workable with a manually operated, semi-automated, or fully automatic packaging machine.

| Items | High Strength VCI Film |

| Corrosion Inhibition Ability | Approved |

| Degree of Contact Corrosion | Approved |

| Puncture Strength,J | ≥0.8 |

| Tear Strength,mN | ≥2000 |

| Tensile Strength,MPa | ≥20 |

Method of Use

Convert VCI plastic film into tubing for packaging metal coils. Make a gusset bag with VCI film when it is used to wrap engines and other medium-sized metal parts. Use VCI film as a cover and bottom cushion if large equipment needs to be packed.

Important

1. Please use VCI packaging film properly as per GB/T 14188 requirements.

2. Ensure metal pieces are clean and dry prior to packaging.

3. The side of VCI film saturated with VCI formulation should face the metal pieces during packaging.

4. Inspect the package against loose seals.

5. Upon packing, remove as much air as possible from the enclosed space. The package should be tightly sealed.

6. Care should be taken not to pollute or damage the package. Measures should be taken to ensure the package is intact in storage and transit.

Storage

High-strength VCI film should be packed in a cardboard box or as per customer specific requirements. Keep VCI plastic film products dry, from direct sunlight, and stored in their original package.