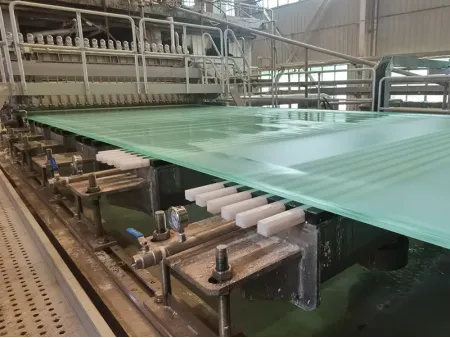

Fourdrinier Tissue Machine

Request a Quote

Tissue paper machine for making kitchen paper and paper hand towel

The primary configuration of the fourdrinier tissue machine comprises an air cushion headbox, fourdrinier former, Yankee dryer, Yankee hood, paper winder, etc.. This tissue making machine possesses significant advantages over the crescent former tissue machine in terms of its higher production rate of paper hand towels and kitchen paper.

Specifications

| Paper Produced | Kitchen paper, tissue paper, paper hand towel |

| Raw Materials | Wood pulp, bamboo pulp, etc. |

| Trimmed Width | 1880-5600mm |

| Basis Weight | 19-45g/m² |

| Production Capacity | 10-115t/d |

| Gas Consumption | 1.9-2.2T (per ton of paper) |

| Energy Consumption | 280-380kW·h (per ton of paper) |

| Water Consumption | 4-6 m³ |

| Machine Speed | 200-1200m/min |

Features

- The paper produced by this machine presents a consistent quality and uniformity, with minimal variations.

- Equipped with an efficient Yankee hood which exhibits an efficient steam consumption performance.

- The design of the forming section is not only user-friendly but also space-saving.

Applications

This paper machine is primarily used for the production of various paper types such as paper hand towels, kitchen paper, and thin sheet paper.

FAQs

The fourdrinier tissue machine is composed of a fourdrinier former and single drying oven, enabling it to produce various types of continuous paper sheets. However, its drying capacity is not unable to process tissue with a very high density. As a result, it is more suitable for the manufacturing of household paper with lower fabric weight.

The selection of materials is primarily based on customer requirements. Typically, smaller components are fabricated using stainless steel, while larger components are constructed using carbon steel with a stainless steel plate cladding on the exterior. This strategic approach results in a considerable reduction in equipment costs.

The fourdrinier paper machine has the ability to be equipped with an open headbox, which is generally suitable for use with low-speed paper machines. However, for machines with speeds exceeding 300m/min, it is recommended to use an air cushion headbox.

We provide comprehensive project services, including design, product supply, installation and commissioning, start-up operation, and technical support, for both new and existing paper mill projects.

Standard Configurations: Former, dryer, paper winder, drive, pneumatic control

Optional Configurations

- Pulping equipment: pulper, refiner, desander, pressure screen, etc.

- Pulping control system: electric cabinet, electrical components, frequency conversion, control system

- Pipeline components in the pulping section: pipes, valves, fittings, etc.

- Paper machine auxiliary machinery: approach flow system, vacuum system, DCS control system, auxiliary electrical control

- Pipeline components in the paper making section: pipes, valves, fittings, etc.

- Post-processing equipment: rewinding machine, packaging machine, paper roll processing equipment, tissue paper processing equipment

- Spare parts: guide rollers, vacuum rolls, paper roll shaft, etc.