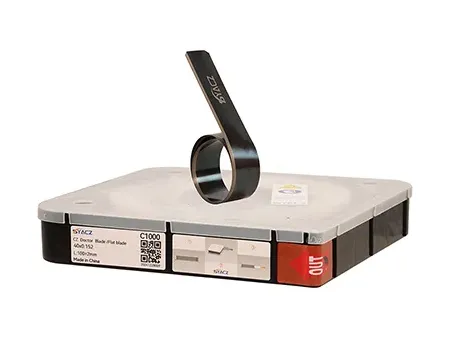

C1000 METAL DOCTOR BLADE

Request a Quote

Ceramic-Coated Doctor Blades

Blade Edge Shapes

- Lamella Blade Edge

- Bevel Blade Edge

Specifications

- Width range: 10mm-60mm

- Width tolerance: ±0.1mm

- Thickness range: 0.152mm-0.3mm

- Thickness tolerance: ±0.005mm

- Hardness: 780-810HV

- Tensile strength: 1850-2100MPa

- Straightness: ≤0.5mm/3000mm

- Coating thickness: 6-8μm

Dimensions

- 10mm×0.15mm×100m

- 20mm×0.15mm×100m

- 20mm×0.2mm×100m

- 30mm×0.15mm×100m

- 30mm×0.2mm×100m

- 35mm×0.15mm×100m

- 35mm×0.2mm×100m

- 40mm×0.15mm×100m

- 40mm×0.2mm×100m

- 40mm×0.3mm×100m

- 50mm×0.15mm×100m

- 50mm×0.2mm×100m

- 60mm×0.15mm×100m

- 60mm×0.2mm×100m

The listed specifications are standard sizes. Customized dimensions can be provided upon request to meet specific printing requirements.

Applications

- These metal doctor blades perform well with corrosive and solvent-based inks, maintaining stability in chemically reactive printing environments.

- Their strong wear resistance makes them suitable for printing plates with high hardness, ensuring consistent performance without excessive blade wear.

- In varnish and specialty ink printing, these doctor blades maintain ink stability, ensuring reliable performance in high-gloss and spot color applications.

- Widely used in full coverage, spot color, and corrugated printing, supporting print jobs that require precise ink metering and extended durability.

Features

- The high-hardness structure (HV800) provides strong resistance to wear and corrosion, preventing color inconsistencies and unwanted streaks caused by ink impurities.

- The ceramic coating enhances durability, ensuring a smooth and stable blade edge over extended use.

- Consistent ink control supports precise color transitions, reducing tonal shifts and minimizing defects such as fine lines or blade marks.

This series of doctor blades are made from 2067 carbon steel and feature a specialized ceramic coating with a thickness of 6-8μm, enhancing wear resistance and extending operational lifespan. Capable of handling press speeds of up to 400m/min, they maintain color consistency by minimizing the impact of edge wear on ink transitions over long print runs.