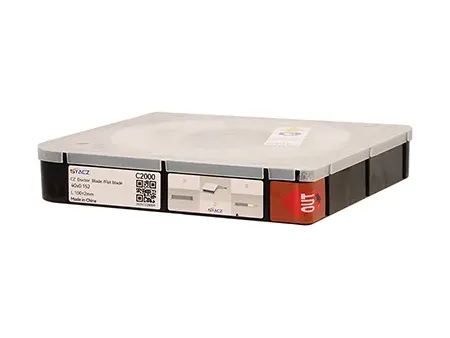

C2000 METAL DOCTOR BLADE

- Lamella Blade Edge

- Bevel Blade Edge

- Width range: 10mm-60mm

- Width tolerance: ±0.1mm

- Thickness range: 0.152mm-0.3mm

- Thickness tolerance: ±0.005mm

- Hardness: 780-810HV

- Tensile strength: 1850-2100MPa

- Straightness: ≤0.5mm/3000mm

- Coating thickness: 10-15μm

- 10mm×0.15mm×100m

- 20mm×0.15mm×100m

- 20mm×0.2mm×100m

- 30mm×0.15mm×100m

- 30mm×0.2mm×100m

- 35mm×0.15mm×100m

- 35mm×0.2mm×100m

- 40mm×0.15mm×100m

- 40mm×0.2mm×100m

- 40mm×0.3mm×100m

- 50mm×0.15mm×100m

- 50mm×0.2mm×100m

- 60mm×0.15mm×100m

- 60mm×0.2mm×100m

- These doctor blades perform well with corrosive and solvent-based inks, ensuring stability and durability in chemically reactive printing environments.

- Their durability and edge stability make them suitable for high-hardness printing plates, preventing premature wear and maintaining consistent performance over long runs.

- They are widely used for spot color, full coverage, and white ink printing, supporting applications that require precise ink metering and smooth transitions.

- Designed for high-speed presses, they enhance production efficiency and print consistency, minimizing downtime caused by blade wear.

- Commonly used in gravure and flexographic printing, they provide reliable ink control for detailed and high-volume print jobs.

- These doctor blades are also used in the electronics, coating, and tobacco packaging industries, where maintaining print precision and durability is a priority.

- Their high-hardness structure (HV800) combined with a dual-layer ceramic coating enhances resistance to wear and corrosion, ensuring long-term performance.

- The reinforced ceramic edge minimizes blade wear, helping to maintain consistent ink transfer and print stability during extended production runs.

- Smooth and precise ink distribution reduces tonal shifts, streaks, and fine blade lines, ensuring sharp and uniform print quality.

- Excellent performance in gradient printing, barcode and QR code printing, and fine text applications, where detailed ink control is essential.

- The high wear resistance helps prevent damage to the edges of the printing plate, contributing to longer plate life and improved production efficiency.

These doctor blades are built for high-speed printing applications, offering enhanced wear resistance and durability. Manufactured with 20MC1 carbon steel as the base material, they feature a dual-layer ceramic coating with a thickness of 10-15μm. Compared to other ceramic-coated blades, this design improves overall performance by 40%, ensuring extended longevity and reliable ink transfer in presses operating at speeds of up to 400m/min. The ceramic composition and increased coating thickness reinforce the blade edge, minimizing surface wear and maintaining print consistency over long production runs. Their ability to handle gradients, fine details, and high-resolution prints, including barcodes and QR codes, makes them a preferred choice for precision printing applications.