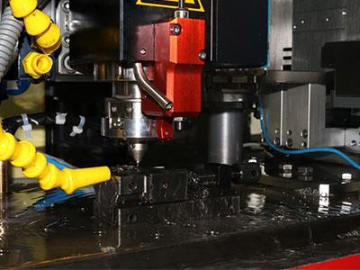

High Speed Wire EDM Machine

The high speed wire EDM machine utilizes a molybdenum wire that improves performance and extends the useful lifetime of the machine. After processing by the high speed wire EDM machine, the surface roughness of the workpiece is Ra 2.5 μm. That means this equipment is suitable for cutting high precision and super hard materials such as the electrodes of EDM machines and stamping dies.

C-TEK's high speed wire EDM machine features high-precision roller type linear guideways to cut the workpiece more quickly. The cutting speed of equipment can reach 250mm/min. In addition, high speed wire EDM machine can ensure the smoothness of the workpiece surface as well as a high precision of 0.015mm during processing.

The high speed wire EDM machine does not need a nozzle, so it is easy to operate and the cost is low.

The high speed wire EDM machine uses a stepper motor to form a cost-effective open loop control system for stable operation.

The high speed wire EDM machine adopts 0.1-0.22mm molybdenum wire as its electrode wire. The molybdenum wire has many advantages such as high tensile strength, good abrasion resistance, long service life and high utilization rate.

With a rectangular body, F-shape wire frame, and a cross-type worktable with high-precision linear guideway, the high speed wire EDM machine can maintain high-precision machining under high loads. With a foldable protective cover, the high speed wire EDM machine can be operated easier and effectively removes the dust so it is environmentally friendly as well.

The user does not need to write the code. They only need to set the processing technology based on the processing graphics, and then the high speed wire EDM machine can start processing. You can also preview processing, display real-time processing, and during taper machining the high speed wire EDM machine can track the processing and display in 3D.

| Parameter | Unit | DK7732A | DK7740A | DK7750A | DK7763A | |||

| Model | ||||||||

| Table travel X.Y.Z | mm | 320*400*300 | 400*500*400 | 500*630*400 | 630*800*500 | |||

| Travel U.V | mm | 60*120 | ||||||

| Max. taper angle | °/mm | Type A: ±6-15°/80(cross slide) Type D: ±15-30°/80 (precise swinging rack) | ||||||

| Diameter of wire | mm | 0.13-0.22 | ||||||

| Wire running speed | m/s | 1-11 | ||||||

| Max.cutting speed | mm²/min | ≥280 | ||||||

| Best surface finish | (μm)Ra | ≤2.5 | ||||||

| Repeat position accuracy | mm | ±0.005 | ||||||

| Precision maching | mm | 0.012(straight line cutting)/0.03-0.06(±15-30° taper cutting) | ||||||

| Cabinet dimension(W*D*H | mm | 580*520*850 | 580*520*850 | 580*520*850 | 580*630*1800 | |||

| Machine dimension(W*D*H) | 1450*1050*1500 | 1700*1060*1700 | 1800*1650*2000 | 2650*2350*2200 | ||||

| Weight | kg | 1800 | 2150 | 3150 | 3250 | |||

| Work tank | ||||||||

| Dirver of worktable | 10 pats 5 phase driven by step motor | |||||||

| Driver of UV axis | 6 pats 3 phase driven by step motor | |||||||

| Max.work piece dimension | mm | 720*520*400 | 840*600*400 | 950*650*500 | 1100*800*600 | |||

| Max.work piece weight | kg | 500 | 600 | 1000 | 2000 | |||

| Work table dimension(W*D) | mm | 720*520 | 760*520 | 500*630 | 630*800 | |||

| Electrical supply | ||||||||

| Standard voltage | 3*220V/3*380V ±10%,50Hz 3.5KVA | |||||||

| Other supply | 220V/415,50/60Hz 3.5KVA | |||||||