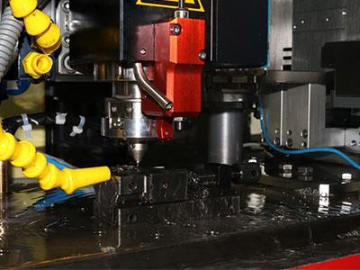

ZNC EDM Machine

Request a Quote

The X and Y axis of our ZNC die sinking EDM are manually controlled. Workers will aim the ZNC die sinking EDM towards the processing part and it will complete the job without the need for an editing and inputting program. This is a very convenient process and eliminates the need for expensive training and specialized equipment.

The ZNC die sinking EDM is mainly used for surface finish or deep hole machining for mold production. After processing, the surface of the workpiece will be extremely smooth and precise.

Features

- More than 20,000 different mold processing conditions can be stored. Multiple sets of MCS storage function.

- With a mirror surface processing circuit, a true mirror effect can be achieved.

- 10 segments auto editing function:

- (1) Manual editing: edit the machining condition using professional knowledge.

- (2) AUTOZ auto editing: max. Depths, initial current and finished procession, machining area selection are provided, and then machining condition editing can be finished automatically.

- (3) FUZZY Z Intelligent condition editing: electrode shape, electrode and work piece material, work piece section area and finished precision selection, depth setting area are provided, and then machining condition edit can be finished automatically. With either the three edit methods above, machining can be completed.

- X.Y.Z axis coordinates can be displayed in metric or imperial units.

- X Y axis Lock function: If the workpiece becomes damaged, the X and Y axes will lock, shutting down the machine.

- Z axis Lock function: Convenient discharge to revise modes with shaking apparatus.

- During operation, the period and other preset conditions can be modified.

- Automatic arcing detection function: if arcing and processing not stable, the computer will automatically adjust the parameters and increase deslagging height until stability is reached.

- It can set 2~10 times discharging for raising the set arbitrary position. This provides good slagging off performance for deep hole machining.

- Secondary discharge is eliminated.

- If the electrode touches the workpiece, there is a function to quickly pull up the electrode.

- Power control (EQU) function for homogenizing the machining effect. And this function can be switched off to accelerating graphite electrode machining.

- Upward discharge processing function makes special processing easier.

- With two independent processing coordinate systems, Male die cavities and cores can be in produced with different coordinate system points.

- If power is lost, the system will restart and automatically load the last machining conditions and coordinates.

- Two independent machining coordinates to protect the electrodes from tensile deformation, improving servo efficiency.

- Coordinates and processing data storage function in the different processing can quickly join the same processing conditions.

- With discharge time and boot time two timer function.

- Two kinds of high voltage circuit can be provided according to customer needs (partial pressure or shunt).

- Use industrial PC-BASE controller and DOM new memory instead of traditional hard disk Reading files faster and stability is very high.

- The screen with automatic protection function, gives the screen a longer service life.

- The new design conforms to the European CE safety specifications of the electric cabinet and I5 LCD (display). It is dustproof, waterproof and tamper-proof.

Parameters

| Model | ZNC 320 | ZNC 430 | ZNC 435 | ZNC 540 | ZNC 650/700 |

| Work tank(WxDxH) (mm) | 880*520*330 | 1100*600*450 | 1130*710*450 | 1300*720*475 | 1650*1100*630 |

| Work table size (mm) | 600*300 | 650*350 | 700*400 | 800*400 | 1050*600 |

| Work table travel X(mm) | 300 | 400 | 450 | 500 | 650/700 |

| Work table travel Y(mm) | 200 | 300 | 350 | 400 | 550 |

| Ram servo travel (Z-axis)(mm) | 180 | 200 | 200 | 200 | 250 |

| Work head travel (W-axis)(mm) | 180 | 280 | 230/280 | 380 | 400 |

| Max.distance from electrode plate to table (mm) | 420 | 450 | 450/480 | 580 | 850 |

| Max. electrode weight(kgs) | 100 | 120 | 120 | 150 | 200 |

| Max. workpiece weight(kgs) | 800 | 1000 | 1200 | 1500 | 2000 |

| Cross weight (kgs) | 1150 | 1360 | 1550/1460 | 1740 | 2950 |

| External dimension (WxDxH)(mm) | 1300*1250*1200 | 1430*1180*1800 | 1470*1150*1980 | 1640*1460*2140 | 2000*1710*2360 |

| Oil tank capacity(Liter) | 250 | 400 | 400 | 460 | 980 |

| Net weight (kgs) | Built-in | 150 | 150 | 180 | 300 |

A Japanese DC servo motor optimizes the processing effects of the equipment because of its high stability.

A Japanese DC servo motor optimizes the processing effects of the equipment because of its high stability. Adopting ballscrews made in Taiwan, the ZNC EDM machine has high precision and can be controlled easily.

Adopting ballscrews made in Taiwan, the ZNC EDM machine has high precision and can be controlled easily. The Z axis has the linear slide made in Switzerland, so the EDM machine has high precision and can be controlled easily.

The Z axis has the linear slide made in Switzerland, so the EDM machine has high precision and can be controlled easily. It is easy to learn and operate with interactive editing.

It is easy to learn and operate with interactive editing.

Standard accessories

- 15” LCD monitor

- 1 pcs working lamp & remote control box

- 1 pcs electrode holder & 1 set cartridge paper filters

- Machine level mounts

- Ballscrews & 3-axis linear scales(5μm)

- 1 set tools with toolbox & clamping kits

- Auto fired detect system & extinguisher

- Operation manual & technical data

Optional accessories

- Coolant system

- System 3R or EROWA Tool holders

- Magnetic table & EDM oil

- 3-axis linear scales (1μm)

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos