Label Counting Machine

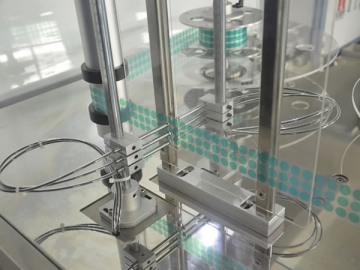

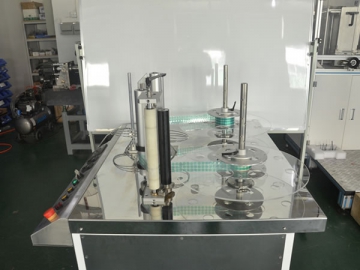

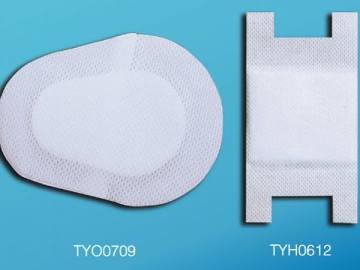

The label counting machine by Hadesheng is a semi-automatic label counting device that timely detects label skipping and provides manual supplement function. Labels with different shapes and sizes are arranged in three rows. For label missing, after the manual supplement, the label counter will automatically move back and calculate the added labels, ensuring an accurate counting result.

By applying Delta control system and magnetic powder clutch, the label counting system realizes good tension control and stable winding. Besides, the human-machine interface makes it easy to set parameters and shows detailed machine condition. In brief, the label counting system is ideally suitable for customers to count labels.

Specifications of Label Counting Machine| Items | Parameters |

| Label testing | Fiber optic sensor |

| Label counting | PLC |

| Label testing and counting control | Touchscreen |

| Length tolerance of label roll | ± 2mm |

| Counting accuracy rate | 100% |

| Counting speed | 20 m/min |

| Max. diameter of label roll | φ 500 mm |

| Max. width of label roll | 250 mm |

| Machine dimensions | 1110 mm×1020 mm×1166 mm |

| Power supply | Single-phase AC 220V, 10A (50-60Hz) |

| Environment temperature | -20-40 ℃ |

| Environment humidity | Less than 75% |

| Environment requirements | No dust, no corrosive materials |

Main Features of Label Counting Machine

1. Unwinding roll and winding roll are adjusted by a tension control system.

2. Driven by a stepping motor, the material winding device possesses adjustable speed, fixed-point stop and forward and back move.

3. The material width can be adjusted within 250 mm.

4. A special roll is installed to ensure stable material unwinding.

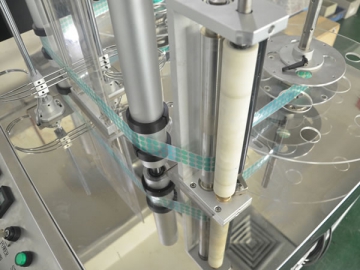

5. With the assistance of a fiber optic sensor, the label counting equipment is suitable for a wide range of materials. In addition, the position of fiber optic sensor can be reset for adjusting devices with different spacings, widths and shapes.

6. A press roll is mounted onto the material winding system, in order for firm lamination.

7. The delta touchscreen provides precise parameter setting and machine control.