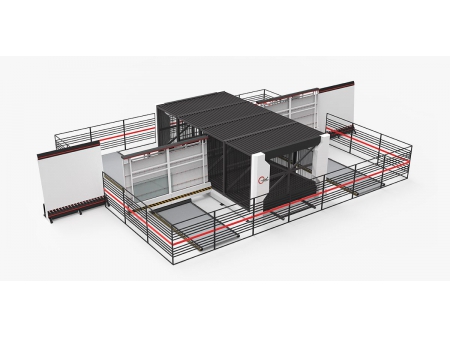

Vertical Buffer System

The vertical buffer system is designed to optimize glass handling and storage both before and after tempering. Composed of shuttles to transport glass between different sections, sorters that organize and store glass in designated positions, and sorter conveyors that ensure smooth movement of glass within the system, this system seamlessly integrates into your production line. It features rails provide a guided path for precise handling, and an advanced control software for error prevention.

The vertical buffer system acts as a buffer, efficiently organizing glass before it enters the tempering furnace or aligning it for insulating glass (IG) production. The system can also be integrated with an automatic batching system to improve loading rates and ensure precise glass pairing.

- Max. glass size: 4200×2500mm/6000×3000mm

- Min. glass size: 400×350mm

- Glass thickness: 3-19mm

- Slot quantity: 25/40/55 per sorter (customizable)

- Max. speed of sorter conveyor: 1.5m/s

- Max. speed of shuttle carriage: 4m/s

- Tilting angle of shuttle carriage: 2-27°

- Ground level: ±5mm/4㎡(2000mmx2000mm)

- Ground bearing capacity: ≥5T/㎡

- Ground strength: ≥C25