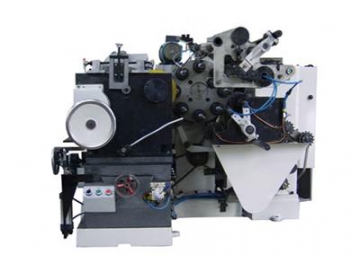

Tube Capping Machine

Description of product

The NMD01 tube capping machine is used to screw the plastic cap onto a printed aluminum tube. The printed tube is then moved through the oven chain through the tube groove of the hat twister. The pushing rod pushes the aluminum tube onto the central mandrel. If the mandrel detects the tube, and it stays in the upper cover station, the nippers are opened, the plastic cover falls onto the nippers, followed by the nippers closing, and the lids being fastened. At the same time, the central mandrel is pushed forward in the direction of the mandrel. At this time, the mandrel rotates in the reverse direction, thus screwing the cap onto the aluminum tube, and completing the capping operation. The discharge plate on the discharge station will push the tube with a screw cover out and into the discharge groove.

| suitable diameter of tube | 11mm-38mm |

| maximum suitable length of tube | 210mm |

| maximum production rate | 60 tubes/minute |

| motor power | 2.2KW |

| dimension | 2074*1210*1525mm |

| whole machine weight | 1800KG |

- Caps are dropped fast, steadily and automatically.

- The tightness is uniform and can be regulated.

- Automatic detection. No tubes, no capping.

- Siemens PLC controls speed and frequency.

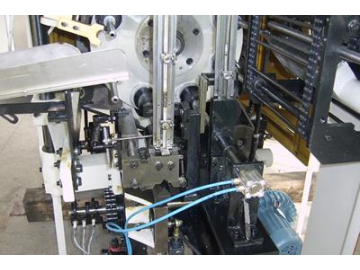

Baiting

Baiting Screw cap

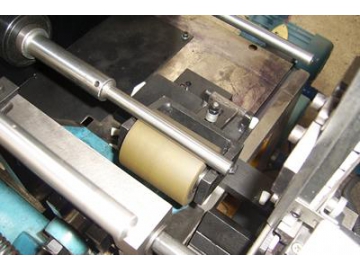

Screw cap Rotating auto chassis

Rotating auto chassis Feeding guide

Feeding guide Mechanical drive chain

Mechanical drive chain Discharge hole

Discharge hole