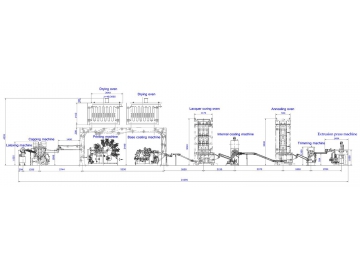

Collapsible Aluminum Tubes Line

Complete Collapsible Aluminum Tube Making Line

The low speed aluminum tube making line is mainly used to produce all kinds of aluminum tubes. The maximum production speed is 60 tubes/ minute.

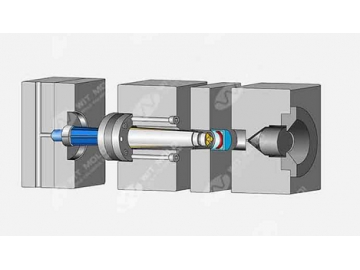

Infeed and Output Aluminum wafer

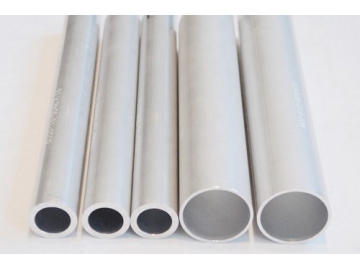

Aluminum wafer

Finished product

Finished product- Maximum production speed: 60/minute

- Production range: 11mm-22mm or 25mm-35mm

- Installed power: 108KW or 135KW

- Dimension: 23000mm×3500mm×4200mm

- Minimum intake pressure: 0.6Mpa

- Minimum gas consumption: 2.5 m³/minute

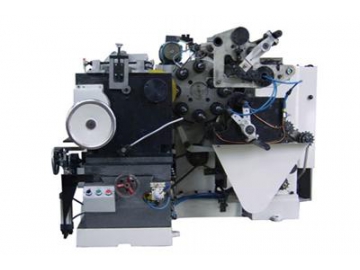

The common aluminum tube machine line produced by our company is fully automatic machine line. This series of production equipment can be used single or combined into a fully automatic machine line for different requirements. The main equipment are aluminum impact extrusion press for aluminum tubes, aluminum tube making trimmer, annealing oven for aluminum tube, internal tube lacquering machine, lacquer curing oven for aluminum tube, aluminum tube accumulator, primer coating machine, aluminum tube printing Machine, drying oven for aluminum tube, aluminum tube capping machine, latex coating machine for sealing aluminum tube, toothpaste cartoning machine,etc.

All the equipment is controlled by Siemens PLC, which have stable performance. All furnaces use FUJI temperature controller to control the temperature automatically. All of the main components and control components are famous brands which have stable and reliable performance. The flow of the product after each process is automatically connected, and the product can automatically in and out. The color touch screen displays the information of production speed and output at any time to facilitate your production management.

The Main Configuration List- PLC Siemens

- Touch screen Pro-face

- Pneumatic element FESTO

- Text display Siemens

- Bearing NSK or NTN

- Proximity switch Bonner

- Photo-electric switch Turck

- Divider Tan Tzu

- Electrical components Schneider or Omron