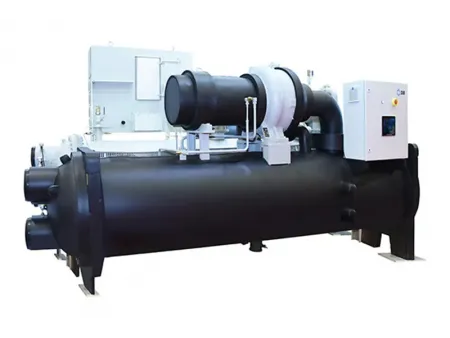

Centrifugal Water Cooled Chiller and Heat Pump, 350kW-2200kW

This product has been discontinued and removed from our shelves.

The centrifugal water cooled chiller and heat pump is designed for cooling, heating, and heat recovery operations in large scale commercial applications. These pumps are often installed in malls, office buildings, factories, and hospitals.

| Model | RLSC350M | RLSC400M | RLSC450M | RLSC500M | RLSC550M | RLSC600M | RLSC650M | RLSC700M | RLSC750M | RLSC800M | RLSC850M | RLSC900M | RLSC950M | RLSC1000M | RLSC1100M | RLSC1200M | RLSC1300MS | RLSC1400MS | RLSC1500MS | RLSC1600MS | RLSC1700MS | RLSC1800MS | RLSC1900MS | RLSC2000MS | RLSC2100MS | RLSC2200MS | ||

| Cooling capacity | RT | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | 1600 | 1700 | 1800 | 1900 | 2000 | 2100 | 2200 | |

| kW | 1230 | 1406 | 1582 | 1758 | 1934 | 2110 | 2285 | 2461 | 2637 | 2813 | 2989 | 3164 | 3340 | 3516 | 3868 | 4219 | 4571 | 4922 | 5274 | 5626 | 5977 | 6329 | 6680 | 7032 | 7384 | 7735 | ||

| Evaporator | Water flow | m³/h | 212 | 242 | 272 | 302 | 333 | 363 | 393 | 423 | 454 | 484 | 514 | 544 | 575 | 605 | 665 | 726 | 786 | 847 | 907 | 968 | 1028 | 1089 | 1149 | 1210 | 1270 | 1331 |

| P.R. | kPa | 76 | 61 | 64 | 63 | 62 | 65 | 74 | 75 | 74 | 76 | 78 | 80 | 82 | 85 | 83 | 84 | 85 | 84 | 81 | 83 | 87 | 89 | 92 | 88 | 89 | 90 | |

| Flow No. | 2 | 2 | 2 | 2 | ||||||||||||||||||||||||

| Connection pipe | DN | 200 | 200 | 200 | 250 | 250 | 250 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 350 | 350 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Condenser | Water flow | m³/h | 256 | 292 | 328 | 362 | 399 | 435 | 471 | 507 | 543 | 579 | 616 | 652 | 688 | 724 | 795 | 869 | 933 | 1004 | 1075 | 1147 | 1221 | 1289 | 1363 | 1434 | 1507 | 1580 |

| P.R. | kPa | 68 | 68 | 62 | 65 | 63 | 68 | 73 | 72 | 74 | 71 | 73 | 74 | 76 | 75 | 73 | 73 | 83 | 84 | 87 | 88 | 90 | 89 | 90 | 94 | 95 | 96 | |

| Flow No. | 2 | 2 | 2 | 2 | ||||||||||||||||||||||||

| Connection pipe | DN | 200 | 200 | 200 | 250 | 250 | 250 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 350 | 350 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Efficiency | Operating power | kW | 227 | 258 | 287 | 303 | 333 | 364 | 394 | 424 | 455 | 484 | 515 | 544 | 575 | 602 | 656 | 724 | 779 | 834 | 892 | 957 | 1016 | 1057 | 1127 | 1185 | 1252 | 1315 |

| COP(1) | 5.42 | 5.45 | 5.51 | 5.8 | 5.81 | 5.79 | 5.8 | 5.81 | 5.79 | 5.81 | 5.8 | 5.82 | 5.81 | 5.84 | 5.9 | 5.83 | 5.87 | 5.9 | 5.91 | 5.88 | 5.88 | 5.99 | 5.93 | 5.93 | 5.9 | 5.88 | ||

| Operating power | kW | 230 | 262 | 293 | 313 | 345 | 376 | 406 | 437 | 470 | 500 | 532 | 563 | 595 | 623 | 679 | 750 | 803 | 862 | 918 | 980 | 1054 | 1095 | 1168 | 1229 | 1298 | 1364 | |

| COP(2) | 5.35 | 5.37 | 5.4 | 5.62 | 5.61 | 5.61 | 5.63 | 5.63 | 5.61 | 5.63 | 5.62 | 5.62 | 5.61 | 5.64 | 5.7 | 5.63 | 5.69 | 5.71 | 5.75 | 5.74 | 5.67 | 5.78 | 5.72 | 5.72 | 5.69 | 5.67 | ||

| Motor | Power | kW | 300 | 300 | 385 | 385 | 385 | 445 | 490 | 490 | 560 | 560 | 630 | 630 | 695 | 695 | 760 | 840 | 840 | 930 | 930 | 990 | 1100 | 1100 | 1200 | 1320 | 1320 | 1450 |

| Power supply | 380/10000V-3ph-50Hz | 380/10000V-3ph-50Hz | 10000V-3ph-50Hz | 10000V-3ph-50Hz | ||||||||||||||||||||||||

| Cooling type | Refrigerant spraying | Refrigerant spraying | Refrigerant spraying | Refrigerant spraying | ||||||||||||||||||||||||

| Weight | Net | kG | 7205 | 7325 | 7510 | 7650 | 7960 | 8146 | 10595 | 10670 | 10750 | 10835 | 10905 | 10974 | 11400 | 11547 | 11715 | 11860 | 18910 | 19400 | 20100 | 20800 | 21400 | 23310 | 23540 | 23820 | 24070 | 24300 |

| Running | kG | 8279 | 8438 | 8702 | 8958 | 9390 | 9641 | 12382 | 12559 | 12700 | 12914 | 13062 | 13189 | 13882 | 14123 | 14458 | 14726 | 22490 | 22730 | 23430 | 24200 | 25100 | 26780 | 27230 | 27680 | 27916 | 28150 | |

| Dimension | L(A) | mm | 4650 | 4650 | 4650 | 4650 | 4650 | 4650 | 5020 | 5020 | 5020 | 5020 | 5020 | 5020 | 5045 | 5045 | 5045 | 5045 | 5190 | 5190 | 5190 | 5190 | 5190 | 5290 | 5290 | 5290 | 5290 | 5290 |

| W(B) | mm | 1850 | 1850 | 1850 | 1850 | 1850 | 1850 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2300 | 2300 | 2300 | 2300 | 2700 | 2700 | 2700 | 2700 | 2700 | 3150 | 3150 | 3150 | 3150 | 3150 | |

| H(C) | mm | 2054 | 2054 | 2054 | 2054 | 2054 | 2054 | 2510 | 2510 | 2510 | 2510 | 2510 | 2510 | 2610 | 2610 | 2610 | 2610 | 3010 | 3010 | 3010 | 3010 | 3010 | 3180 | 3180 | 3180 | 3180 | 3180 | |

Remark

1. COP(1) for in/out cooled water 12/7C°.in/out cooling water 30/35C°

2. COP(2) for in/out cooled water 12/7C°.in/out cooling water 32/37C°

* Standard export packaging.

* Normally, we will deliver the machine 50 days after we receive the advanced payment from our clients. For urgent cases, delivery time is negotiable.

* Payment amount can be divided into two parts, including 30% T/T before manufacture and 70% T/T before shipment.

* Warranty is 12 months for the complete unit, starting from shipping date.

* Quotation validity is 30 days after the issue date.

- Aerial pneumatic technology. The optimized centrifugal compressor aerial design software, specially designed by Ruidong, greatly improves the efficiency of the compressor unit.

- Keyless connection technology. The keyless connection between the impeller and the main axis is patented by Ruidong. The technology greatly improves the service life of the impeller.

- Wide range of operation. The adoption of pre-rotating blade technology optimizes machine operation under some loads.

- The control of oil and refrigerant. Lubricating oil is recycled and compressed so as to guarantee the stability and safety of operation of the machine set.

- Energy saving and environmentally friendly. The refrigerant R134a is an environmentally friendly, non-toxic and safe product.

- Intelligent control. Automatic control and operation leads to maximum efficiency during operation.