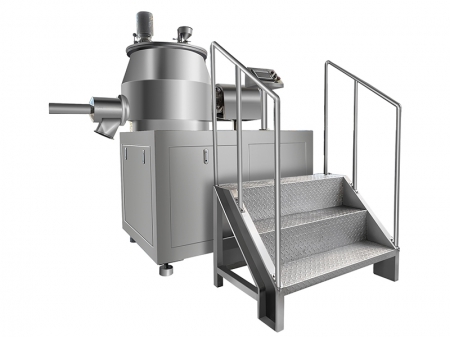

High Shear Granulator

Request a Quote

HLSG Series

High shear granulator is suitable for the pharmaceutical, chemical, food and other industries for mixing powders with powders, and granulating powders with binders. It features easy operation, stable performance and meets GMP requirements.

Technical Specifications

| Model | |||||||||

| Bowl capacity | 10L | 30L | 50L | 100L | 200L | 300L | 400L | 600L | 800L |

| Work capacity | 2-8L | 6-24L | 10-40L | 20-80L | 40-160L | 60-240 | 100L-300L | 150L-440L | 200L-600L |

| Material feeding capacity (specific gravity 0.5g/cm3) | 1-4 kg/batch | 3-12 kg/batch | 8--20 kg/batch | 15--40 kg/batch | 30--80 kg/batch | 30---120 kg/batch | 50—150 kg/batch | 75—220 kg/batch | 100—300 kg/batch |

| Operation time | Mixing: 2min (Approx.) Granulation: 7-14min/batch (Approx.) | Mixing: 2min (Approx.) Granulation: 7-14min/batch (Approx.) | Mixing: 2min (Approx.) Granulation: 7-14min/batch (Approx.) | Mixing: 2min (Approx.) Granulation: 7-14min/batch (Approx.) | Mixing: 2min (Approx.) Granulation: 7-14min/batch (Approx.) | Mixing: 2min (Approx.) Granulation: 7-14min/batch (Approx.) | Mixing: 4min (Approx.) Granulation: 10-15min/batch (Approx.) | Mixing: 8min (Approx.) Granulation: 15-20min/batch (Approx.) | Mixing: 8min (Approx.) Granulation: 5-15min/batch (Approx.) |

| Finished granule size | Approx. Φ0.14-Φ1.5mm(12mesh-100 mesh) | Approx. Φ0.14-Φ1.5mm(12mesh-100 mesh) | Approx. Φ0.14-Φ1.5mm(12mesh-100 mesh) | Approx. Φ0.14-Φ1.5mm(12mesh-100 mesh) | Approx. Φ0.14-Φ1.5mm(12mesh-100 mesh) | Approx. Φ0.14-Φ1.5mm(12mesh-100 mesh) | Approx. Φ0.14-Φ1.5mm(12mesh-100 mesh) | Approx. Φ0.14-Φ1.5mm(12mesh-100 mesh) | Approx. 0.10-Φ2.5mm |

| Impeller motor | 2.2KW 6-pole | 3KW 6-pole | 5.5KW 6-pole | 7.5KW 6-pole | 15KW 6-pole | 18.5KW 6-pole | 22KW 6-pole | 30KW 6-pole | 37KW 6-pole |

| Impeller rotary speed (variable frequency) | 50-500 RPM | 25-500 RPM | 25-500 RPM | 30-250 RPM | 30-260 RPM | 30-220 RPM | 20-200 RPM | 20-200 RPM | 20-200 RPM |

| Chopper motor | 0.75KW 2-pole | 1.1KW 2-pole | 1.5KW 2-pole | 3KW 2-pole | 4KW 2-pole | 5.5KW 2-pole | 7.5KW 2-pole | 11KW 2-pole | 11KW 2-pole |

| Chopper rotary speed (variable frequency) | 50-3000 RPM | 50-3000 RPM | 50-3000 RPM | 50-3000 RPM | 50-3000 RPM | 50-3000 RPM | 50-3000 RPM | 50-3000 RPM | 50-3000 RPM |

| Compressed air | 0.15m3 0.7Mpa (supplied by user) | 0.1.5m3 0.7Mpa (supplied by user) | 0.3m3 0.7Mpa (supplied by user) | 0.3m3 0.7Mpa (supplied by user) | 0.3m3 0.7Mpa (supplied by user) | 0.5m3 0.7Mpa (supplied by user) | 0.5m3 0.7Mpa (supplied by user) | 0.5m3 0.7Mpa (supplied by user) | 0.6m3 0.7Mpa (supplied by user) |

| Cooling water connection | Φ8mm | Φ8mm | Φ8mm | Φ8mm | Φ10mm | Φ10mm | Φ10mm | Φ10mm | Φ12mm |

| Compressed air port | Φ8mm | Φ8mm | Φ8mm | Φ8mm | Φ10mm | Φ10mm | Φ10mm | Φ10mm | Φ12mm |

| Machine dimension (L×W×H) | 1280×530×1320 mm | 1500×550×1350 mm | 1750×600×1620 mm | 1760×600×1660 mm | 2180×810×1950mm | 2420×1060×2150mm | 2420×1060×2150mm | 2980×1200×2500mm | 3180×1500×2800mm |

| Weight | 350kg | 450kg | 600kg | 800kg | 1300kg | 1500Kg | 1800kg | 2200kg | 2700kg |

Features

- PLC control (HMI optional) is adopted for controlling in manual and automatic mode, allowing process data editing;

- Both agitator impeller and chopper adopt variable frequency drive for speed regulation, easy control of granule size;

- Rotating shaft chamber is designed with air seal, eliminating the problem of dust adhesion; It has automatic cleaning function;

- Conical shaped mixing bowl provides even mixing of materials; By circulating cooling liquid through the jacket at bottom of the mixing bowl, constant temperature is better performed in comparison with air cooling method, thus improving the quality of granules;

- Bowl lid is automatically opened and closed;

- Compatible with drying equipment; Large size wet granulator is configured with ladder for easy operation;

- Impeller lifting system facilitates cleaning of impeller and bowl;