ZL205A (ZAlCu5MnCdVA) Aluminium Welding Wire

Request a Quote

Welding Consumables

Aluminium-copper filler metal for MIG and TIG welding and repairing of cast aluminium alloys

- Chemical Designation: ZAlCu5MnCdVA

- Standard: GB/T 1173-2013

Chemical Composition (%)

| Cu | Mn | Cd | V | Ti | Zr | Be | Al |

| 4.6-5.3 | 0.3-0.5 | 0.15-0.25 | 0.05-0.3 | 0.15-0.35 | 0.15-0.25 | 0.005-0.6 | Rest |

Features

- High-strength aluminium-copper wire developed for welding and repairing cast aluminium alloys

- Alloyed with manganese, vanadium, and zirconium to enhance mechanical properties and performance at elevated temperatures

- Offers improved weldability and casting repair results, ensuring stronger, more reliable joints in demanding applications

Available Sizes

- Welding wire: 0.8/1.0/1.2/1.6/2.0/2.4/3.0/3.2/4.0/5.0/6.0mm

- Spool: D300 (9kg), D270 (7kg), D200 (2kg), D100 (0.5kg)

Applications

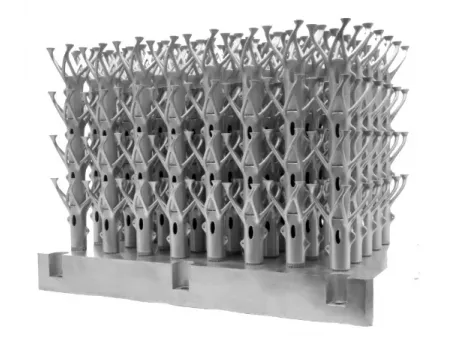

- Commonly used in 3D printing of aluminium parts requiring structural strength

- Suitable for welding sand-cast aluminium components exposed to high dynamic or static loads

- Ideal for repairing or producing castings with simple geometries that demand reliable mechanical performance

Packaging

- MIG wire diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm

- Package: D300 (9kg/spool), D270 (7kg/spool)

- MIG wire diameter: 1.2mm, 1.6mm

- Package: drum D660 (100kg/drum)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (10kg/box)

- TIG wire diameter: 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil

Recommended Welding Method

Suitable for both MIG and TIG welding processes. AC TIG welding with pure argon shielding gas is recommended to ensure arc stability and weld quality. Before starting, clean the part to be welded thoroughly to remove any oil, dust, or surface oxidation. Moisture on the base metal or filler wire should be avoided to prevent weld defects.