PE Breathable Film Line

Extrusion line for producing breathable film of baby diapers and sanitary napkins

Our PE breathable film line features our independently designed screws, known for excellent plasticizing quality, high wear resistance, and stable extrusion. The cast film line is equipped with a longitudinal multi-stage stretching system, allowing adjustable breathability as needed. Precise speed, pressure, and temperature control ensure uniform moisture permeability throughout the production process, resulting in smooth winding of the final product.

- Maximum Film Width: 1,600mm, 2,200mm, 3,200mm

- Thickness range: 15-30gsm

- Maximum Winding Speed: 280m/min

- Production Volume: 800kg/h

- Equipment Dimensions: 25m *10m * 5m

- Total Installed Power: 550-1,000kW

- Often operated in single-extruder, but also available in dual-extruder mode

- Equipped with automatic die and defect detection

- Four-stage stretching with flexible adjustment range

- Adjustable stretching gap

- Heated by oil temperature controller

- Secondary embossing required for making sanitary pads

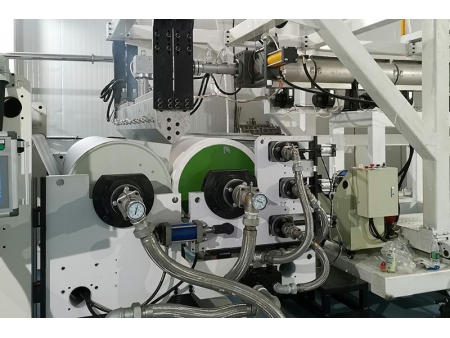

- Extruder

- Die

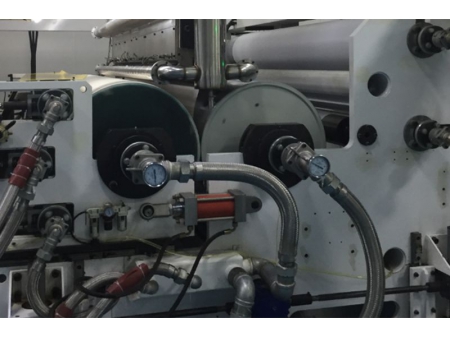

- Cast system

- Thickness gauge

- MDO system

- Mold temperature controller

- Corona treatment

- Inline slitting

- Winding

- Film roll

PE film is breathable while waterproof.

PE breathable film is primarily used in the hygiene industry for products like baby diapers, female sanitary pads and liners. It is also suitable for applications where both waterproofing and breathability are desired, such as making disposable surgical gowns, breathable clothing, fresh fruit and vegetable packaging, medical packaging, and coverings for construction materials.

Pinholes in the film

Insufficient drying of the raw material

Winding defects

Improper adjustment of film thickness

Tight film

Excessive tension during winding

Varying thickness of the film without changing settings or dies

Poor material dispersion

Low breathability of the film

Insufficient stretching ratio

Poor transverse strength of the film

Excessive stretching ratio