Tube and Pipe for Hydraulic Prop

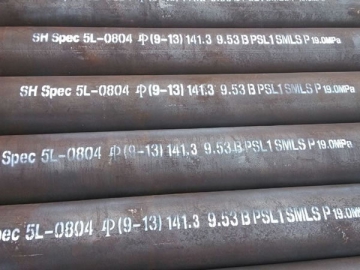

Specifications

Standards: GB/T17396-2009

Main Materials: 20#, 45#, 27SiMn

Sizes:

O.D.: 51-406mm

Wall thickness: 6-70mm

Length: Any length, or Customized

Applications

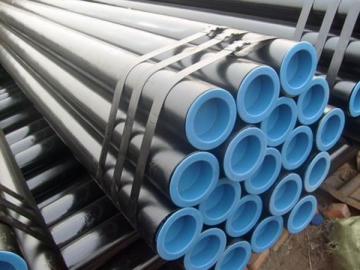

The seamless steel tube for hydraulic prop is mainly used for hydraulic system, plastic machinery, injection molding machinery, rubber machinery, metal forming machinery, die casting machinery, construction machinery, air conditioning system, shoemaking machinery, etc.

The hydraulic prop pipe, ideal for making hydraulic mining prop and hydraulic roof support, is engineered from superior carbon structural steel, with addition of one or several kinds of alloy elements which can enhance steel strength, toughness and hardenability. This kind of structural steel will receive a series of thermal treatments including tempering, chemical heating, surface hardening, etc. Compared with carbon structural steel, it comes with superior comprehensive mechanical properties.

Chemical Compositions| Grade | Compositions | ||||||||

| C | Si | Mn | P | S | Ni | Cr | Cu | Mo | |

| 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | ≤0.35 | ≤0.35 | ≤0.25 | ≤0.25 | ≤0.20 | - |

| 27SiMn | 0.24-0.32 | 1.10-1.40 | 1.10-1.40 | ≤0.35 | ≤0.35 | ≤0.25 | ≤0.25 | ≤0.20 | ≤0.15 |

| Grade | Mechanical Properties | ||||||

| Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact energy (J) | Hardness HBS | |||

| 45 | ≥600 | ≥355 | ≥16 | ≥39 | ≤197 | ||

| 27SiMn | ≥980 | ≥835 | ≥12 | ≥39 | ≤21 | ||

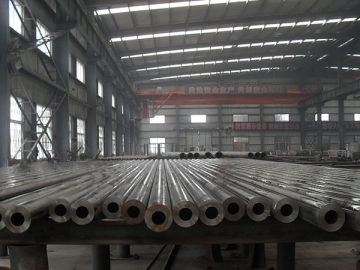

Production Capacity: 20,000 tons per year

Production Cycle, Packaging, Delivery

The seamless steel tube can be finished in a production cycle of about two weeks, ensuring in-time delivery. Without special requirements, we will provide bundling package. In addition, we offer export packages if required.

Raw Materials

Superior steels from Tianjin Iron and Steel Co., Ltd. resulting in reliable quality.

Production Process

Pipe billets inspection—Cutting of qualified billets—Heating—Hot piercing—Tube rolling—Stretch reducing—Cooling on cold bed—Straightening—Cutting—Eddy current testing—Manual surface testing—Packaging—Weighing and Putting in storage