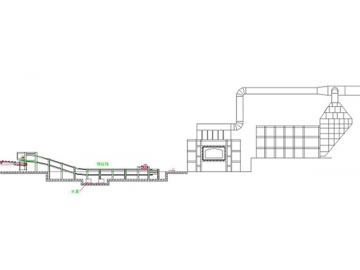

Continuous Casting Line for Aluminum Ingot Processing

Request a Quote

We design and manufacture continuous casting machine for global aluminum ingot processing. Our continuous casting line for aluminum ingot consists of ladle refining furnaces, aluminum melting furnace, ladle/furnace for aluminum casting, cooling conveyor, baler, and production management system. This continuous casting line adopts regenerative burner combustion system.

Aluminum Melting Furnace

Parameters

- Melting capacity: 5-7T/H(continuous operation in rated work situation)

- Melting temperature: 700℃(maximum temperature no more than 800℃)

- Energy: heavy oil, natural gas, coal, and biomass pellet

- Energy consumption: with regenerative natural gas burner at 65-75m³/T

- Burning rate: 1.0%

- Power supply: 3-phase AC, rated voltage: 380V

Furnace Structure

- Furnace rack: It adopts full welded construction. The electric furnace door is with up to open design and protected by splicing cast iron.

- Furnace lining and insulation parts is constructed by ceramic fiber insulation boards, high alumina refractory bricks, broken brick, lightweight insulation brick, anti-seepage castable and advanced castable.

Ladle/Furnace for Aluminum Casting

- Mold use: producing aluminum alloy ingot

- Mold material: heat-resistant cast iron

- Rated capacity: 5T/H (maximum capacity 8T/H)

- Mold cooling method: water cooling

- Water supply pressure: 0.25MPa (consumption: 64 m³/H)

- Demolding method: fully automatic double hammer

- Filling Method: wheel type

- Motor: 4KW/380V-415V/50Hz

- Speed control method: frequency control

Dispensing system

The dispensing system uses chain adjustment auxiliary wheel with chain protection cover to adjust the small deviation of the dispenser in the aluminum ingot manufacturing. This design can effectively avoid mechanical damage and stuck of bearing. It controls the aluminum flow to ensure the smooth casting, reduce the amount of dross (oxide), and help plan production process.

Aluminum ingot