EDM Machine Control Cabinet

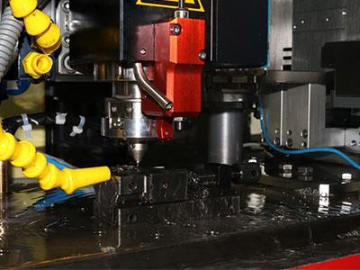

The EDM machine consists of an EDM machine control cabinet and an EDM machine body. A C-TEK EDM machine control cabinet can also be used with an EDM machine body purchased from other companies, so customers can benefit from C-TEK quality no matter what.

C-TEK EDM machine control cabinets come in 4 types. The E type EDM machine control cabinet is designed for CNC EDM machine control cabinets and high precision ZNC EDM machine control cabinets. A type and C type EDM machine control cabinets are designed for use as ZNC EDM machine control cabinets.

We will check and evaluate the EDM machine body for the customer before sending the EDM machine control cabinet. We will provide a solution to the customer based on the situation of the EDM machine body, servo motor and the linear scale.

Our EDM machine control cabinets have good sealing properties so as to prevent dust, oil, and water ingress. In addition, the equipment can be used stably in high temperature and humid environments.

The following are 4 types C-TEK EDM machine control cabinets. Customers can directly choose these EDM machine control cabinets according to the machining current.

- A type EDM machine control cabinet

C type EDM machine control cabinet

C type EDM machine control cabinet E type EDM machine control cabinet

E type EDM machine control cabinet All-in-one EDM machine control cabinet

All-in-one EDM machine control cabinet

| Model | 50A | 75A | 100A |

| Control method and axis | Close (Z-asix) | ||

| Min. setting unit | 0.005mm(0.001mm) | ||

| Max. setting unit | 9999.995mm(9999.9999mm) | ||

| Coordinate system | INC, ABS | ||

| Screen display | 15"LCD, color | ||

| Control system | Industrial PC | ||

| Inching | 0.005mm(0.001mm)unit x1,x5,x10 | ||

| Program file storage | Over 10000 sets | ||

| Max. machining current (A) | 50 | 75 | 100 |

| Total power input (KVA) | 4.5 | 6 | 10 |

| Max. material removal rate (mm/min) | 360 | 560 | 700 |

| Electrode wear rate (%) | < 0.2 | ||

| Best surface roughness (μmRa) | 0.18 | ||

| External dimension (mm) | 830*720*1850 | 830*840*1850 | |

| Packing dimension (mm) | 930*820*2050 | 930*940*2050 | |

| Net weight (Kg) | 270 | 350 | |

| Mahchining setting amount per set | 1 | ||

| Steps | 10 | ||

| Machining model | Up sparking, down sparking | ||

| Orbit cutting | No | ||

| Continuous machining Max. hole amount | 1 | ||