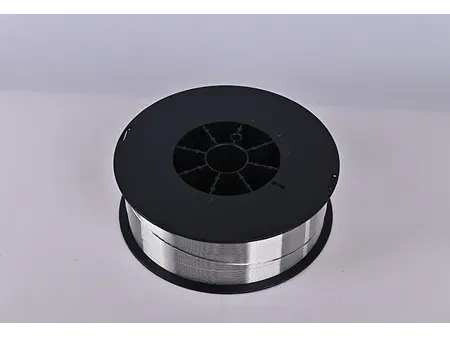

ER 3A21 Aluminium Welding Wire

Request a Quote

Welding Consumables

Aluminium-manganese filler metal for MIG and TIG welding of aluminium-manganese alloys

- Standard: GB/T3190-2020

Chemical Composition (%)

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Al | Others | |

| Each | Total | ||||||||

| ≤0.60 | ≤0.70 | ≤0.20 | 1.0-1.6 | ≤0.05 | ≤0.10 | ≤0.15 | Rest | ≤0.05 | ≤0.10 |

Features

- Designed for welding aluminium-manganese alloys, offering slightly higher strength than pure aluminium

- Cannot be strengthened through heat treatment, but cold working improves mechanical properties effectively

- High plasticity in annealed condition, good corrosion resistance, and excellent weldability make it a versatile option for general fabrication

Available Sizes

- Welding wire: 0.8/1.0/1.2/1.6/2.0/2.4/3.0/3.2/4.0/5.0/6.0mm

- Spool: D300 (9kg), D270 (7kg), D200 (2kg), D100 (0.5kg)

Applications

- Ideal for welding parts that operate in liquid or gas environments and require high plasticity and good weldability

- Commonly used for fuel tanks, gasoline or lubrication pipes, and a variety of liquid containers

- Also suitable for deep-drawn components and other low-stress parts that benefit from corrosion resistance and formability

Packaging

- MIG wire diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm

- Package: D300 (9kg/spool), D270 (7kg/spool)

- MIG wire diameter: 1.2mm, 1.6mm

- Package: drum D660 (100kg/drum)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (10kg/box)

- TIG wire diameter: 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil

Recommended Welding Method

Performs well with both MIG and TIG welding, especially when using AC TIG with pure argon as shielding gas. To avoid porosity or weak joints, make sure the workpiece and filler are free from moisture or surface contaminants before starting.