ER 4010 (AlSi7Mg) Aluminium Welding Wire

Request a Quote

Welding Consumables

Aluminium-silicon filler metal for MIG and TIG welding and repairing of aluminium alloyed with silicon

- Chemical Designation: AlSi7Mg

- Standard: AWS A5.10, GB/T10858-2023

Chemical Composition (%)

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Al | Be | Others | |

| Each | Total | |||||||||

| 6.5-7.5 | ≤0.20 | ≤0.20 | ≤0.10 | 0.30-0.45 | ≤0.10 | ≤0.20 | Rest | ≤0.0003 | ≤0.05 | ≤0.15 |

Features

- Designed for welding aluminium-silicon alloys, especially those requiring good strength, toughness, and fatigue resistance

- Commonly used in high-speed rail systems for welding joints and fastening components

- Delivers stable mechanical performance and durable welds in demanding transport applications

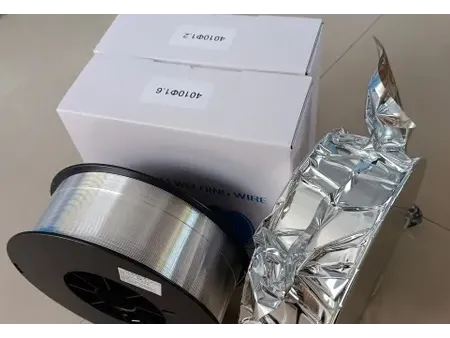

Available Sizes

- Welding wire: 0.8/1.0/1.2/1.6/2.0/2.4/3.0/3.2/4.0/5.0/6.0mm

- Spool: D300 (9kg), D270 (7kg), D200 (2kg), D100 (0.5kg)

Applications

- Used in railway and high-speed rail systems for welding critical components such as rail joints and fastening assemblies

- Suitable for joining and repairing aluminium structures that demand high strength, toughness, and fatigue resistance

Packaging

- MIG wire diameter: 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm

- Package: D300 (9kg/spool), D270 (7kg/spool)

- MIG wire diameter: 1.2mm, 1.6mm

- Package: drum D660 (100kg/drum)

- TIG wire diameter: 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm, 5.0mm, 6.0mm

- Package: 1000mm length (10kg/box)

- TIG wire diameter: 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm, 4.0mm

- Coil inner diameter: D450mm, D300mm

- Package: 10-17kg/coil

Recommended Welding Method

For best results, this welding wire should be used with MIG or TIG welding processes, ideally under AC current with pure argon shielding gas. Before starting, make sure the weld area is thoroughly cleaned and that both the workpiece and welding wire are completely dry and free from contaminants.