Anodized Aluminium Coil & Sheet

What is Anodizing

Anodizing is an electrolytic surface treatment process used to generate oxide coatings onmetal sheets. The oxide layer presents surprisingly high hardness, and will never fall off from the metal surface, so provides continuous protection against water, heat, or corrosion. It also produces an excellent decorative finish.

Aluminium anodizing technique provides higher hardness, longer life and better wear resistance for aluminium alloy than traditional surface treatment technique does, and makes aluminium product applicable in more fields. Globally, it is the best as well as the most widely-accepted surface treatment technology for aluminium products.

Product Specification| Alloy | 1xxx, 3xxx, 5xxx, etc. |

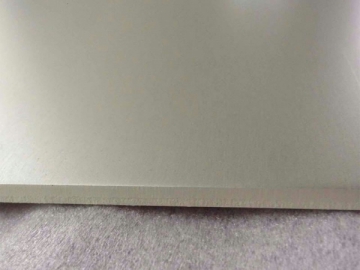

| Thickness | 0.1mm~4.0mm |

| Width | 100mm~1650mm |

| Surface treatment | anodizing |

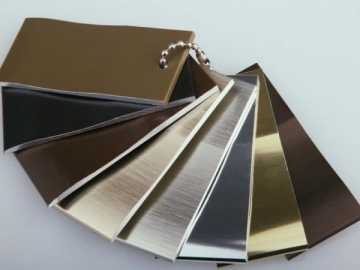

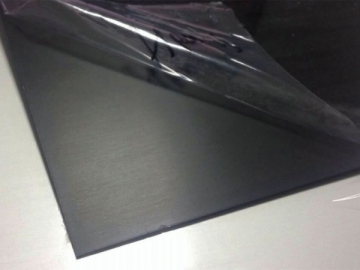

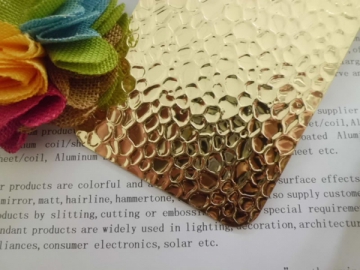

| Surface finishing | specular, matte, drawing, titanium sliver, semi-specular, hammer paint, texture, etc. |

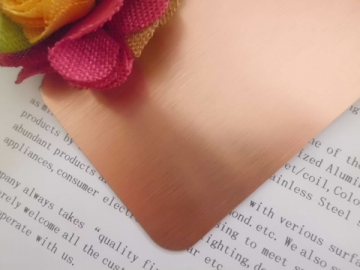

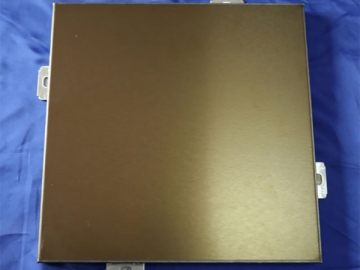

| Color | sliver, golden, rose gold, black, stainless steel color, bronze, etc. |

Anodized Aluminium Sheets in SOLAR

SOLAR anodized aluminium coil is lightweight and easily-processed, during which pretreatment is unnecessary so the cost is saved considerably. Anodizing treatment enhances aluminium coils' performance in terms of weatherability, and fire and corrosion resistance.

SOLAR processes aluminium coils from alloys of different grades according to clients' requirements. The coils range in thickness from 0.1mm to 4mm, and in width from 100mm to 1650mm. Different colors and finishing like specular, drawing, and matte are available to meet customers' individual needs.

Applications

Anodized aluminium coil is extensively applied in: mechanical accessory, car parts, aircraft parts, precision instrument, wireless equipment, building and decorative materials, machine case, lighting products, manual craft, household appliance, interior decoration, ceiling, furniture, and car interior decoration, just to name a few.

Main Features

1. Lightweight: specific gravity of aluminium sheet is only about 1/3 of that of stainless steel. Being easily formed and processed, it is especially suitable for making small accessories

2. Oxide layer control: 2μm-40μm

3. Easily cleaned: anodized aluminium material is not likely to get soiled by dirt or handprints. It is antistatic so dust won't accumulate on its surface

4. High hardness: anodizing treatment gives the metal surface an oxide layer of extremely high hardness reaching that of a diamond, protecting the metal from scratch

5. Good weatherability: anodized sheet is resistant to corrosion and ultraviolet. Used indoor, an aluminium sheet covered by standard 3μm-thick oxide will never fade or get corroded. Thickened anodized plate (10μm) is designed for outdoor applications

6. Environmentally friendly: anodized sheet is fireproof and non-toxic. All of the products in SOLAR have been certified by RoHS and SGS

7. Uniform metal finish: no color difference; and the oxide layer will never fall off

8. Energy saving: anodized sheet features high reflectivity and energy efficiency, and is recyclable

9. Decorative: an excellent decorative material

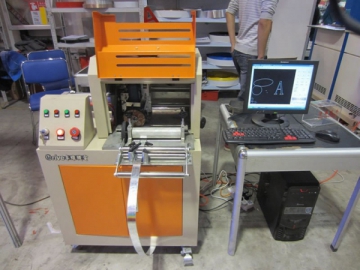

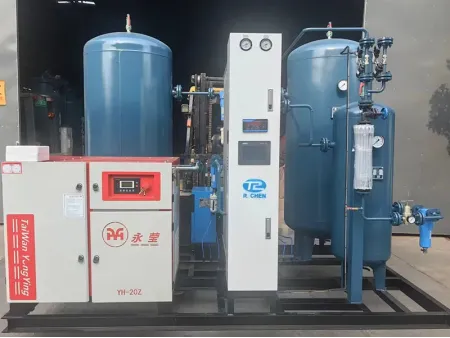

Continuous Coil Anodizing

Continuousaluminium coil anodizing line provides a solution for color difference and oxide nonuniformity that commonly seen in traditional anodizing process. The uniform thickness of oxide layer ensures long service life as well as bright finish of aluminium sheets.

Packaging

At SOLAR, all of the products are packed with standard waterproof film, and are fixed firmly on wooden pallets.