Corrugated Cardboard Production Line

When choosing the right models of machines for your corrugated cardboard production line, you'll need to take into account the parameters and size and shape you need. Below are different models, raw materials, and afer-sales services that Shengli provides for our carton machinery.

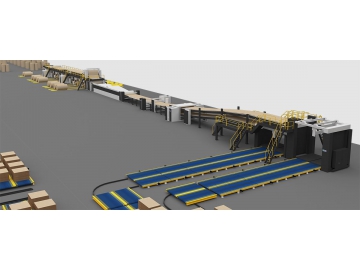

As many of our clients needed high speed machine, we have developed a single layer corrugated cardboard production line that can process 150m/min of single layer cardboard with a width ranging from 1800mm to 2200mm. This cost-effective cardboard production line reduces the amount of labor and time needed in production. The corrugated line is about 25 meters long, but can be customized to fit customers' needs.

Depending on the size and scale of your project, our multi-layer corrugated cardboard production line features a variety of machines that operate conveniently at adjustable speeds, including mill roll stands, corrugated rollers, core paper preheaters, glue machines, slitters, and auto stackers.

- Base paper

- Corrugated cardboard

2. Technical parameters of Corrugated Cardboard Production Line

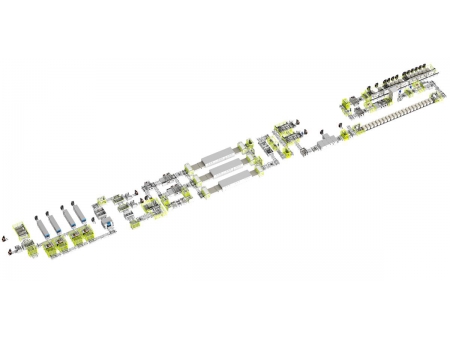

(1)Option 1: 150m/min, working width 1400mm, 1600mm, 1800mm, or 2000mm in three layers, five layers or seven layers.

(2)option 2: 200m/min, working width 1400mm, 1600mm, 1800mm, 2000mm, or 2200mm in three layers, five layers or seven layers.

(3)Option 3: 260m/min, working width 1800mm, 2000mm, or 2200mm in three layers, five layers or seven layers.

3. Machine size and shape

(1)Option 1: The three layer machine is 60 meters in length, five layers is 80 meters, seven layers is 100 meters.

(2) Option 2: The three layer machine is about 60 meters in height, five layers is 80 meters,seven layers is 100 meters.

(3) The 1400 model width is 6.1 m, 1600 model width is 6.3m, 1800 model width is 6.5m, 2000 model width is 6.7m, 2200 model width is 7.5m.

4. Raw materials and after-sales services.

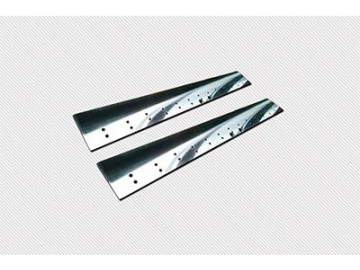

(1)Our corrugated rollers, preheaters, auto stackers, and other machines use steam heating only, which reduces the price of coal and oil purchases.

(2)Glue for corrugated cardboard is made of starch, caustic soda and borax in a formula we will provide. For some special projects, where weather may cause the cardboard to warp, we recommend including a special additive.

(3) After the machine finish as ordered, we will test machine in our factory, not only the machine idling, it will produce the cardboard lively in our factory to ensure the machine is qualified before leaving our factory.

(4) Our engineers will install and repair machines onsite at your factory. The installation time takes about 30 business days. Then we will spend 15 days training your employees to safely and accurately operate machines.

(5) Most of our machine spare parts, such as the bearings, electronic components, etc., are made to international standards or imported so it is easy for customers to purchase spare parts if needed. We keep spare parts in storage and run timely deliveries so your factory can run normally.

Related names:

Corrugated cardboard machine | Cardboard printer | Paperboard processing equipment