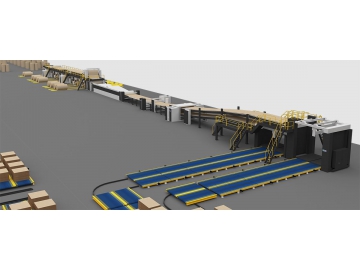

Corrugated Cardboard Production Line (Single Face)

As many of our clients needed high speed machine, we have developed a single layer corrugated cardboard production line that can process 150m/min of single layer cardboard with a width ranging from 1800mm to 2200mm. This cost-effective cardboard production line reduces the amount of labor and time needed in production. The corrugated line is about 25 meters long, but can be customized to fit customers' needs. Each of our machines undergo strict testing before leaving our facility to ensure reliable and standard operation.The production line features a mill roll stand, corrugated rollers, core paper preheater,glue machine, slitter, scorer, and cut off machine, and auto stacker.

Samples made by Carton MachinerySingle Machines Introduction of Cardboard Production Line

| No | Parameter name | unit | Parameter |

| 1 | Working width | mm | 1800-2200 |

| 2 | Max mechanical speed | m/min | 150 |

| 3 | Slitter knife quantity | knives | 5/6 |

| 4 | Mini slitter width | mm | 250 |

| 5 | Arrange knife time | seconds | <10 |

| 6 | Stack paperboard length | mm | 300-1400 |

| 7 | Arrange knife precision | mm | ± 0.5 |

| 8 | Stack height | mm | 300 |

| 9 | Cut off precision | mm | ± 1.0 |

YZJ1/2 Hydraulic Mill Roll Stand

1)Holding diameter max/min: Ф1500mm / Ф300mm

2)Max. holding paper weight: 2500kg

3)Range of Width: 1400-2000 mm

4)CNC machining ensures high precision.

5)Hydraulic electric valves from Taiwan, hydraulic motor pump head from Japan, low voltage components from Schneider.

YZJ3 Hydraulic Mill Roll Stand

1)Holding diameter max/min: Ф1600mm/Ф320mm

2)Maxx holding paper weight: 3500kg

3)Range of Width:2200mm

4)CNC machining ensures high precision.

5)Hydraulic electric valves from Taiwan, hydraulic motor pump head from Japan, low voltage components from Schneider.

SDW3 Twin Corrugated Rollers Single Face Machine

1)Design speed 220m/min.

2)Working width: 1800-2200mm.

3)The machine can change either set of corrugated rollers within 15-30 seconds and recover normal production in 2-3 minutes.

4)Two sets of corrugated rollers in one unit are made of chromed and tungsten carbide and are easy to replace.

5)Corrugated roller uses a rotary structure, hydraulic power to drive, and oil cylinder to lock. Changing the type of corrugated rollers mid-operation won't cut the surface paper.

6)Operator can replace any set rollers within two minutes without stopping the machine.

7)When one set of corrugated rollers is working, the other set runs at a low speed to save energy.

1)Design speed: 150m/min, 200m/min, 260m/min

2) Working width:1400-2200mm

3)CNC machining ensures high precision.

4)Glue thickness can be adjusted automatically according to the machine's speed.

5)When the paper breaks, an electric eye tracking device automatically decreases speed.

6)PLC and inverter from Taiwan, reduced speed motor from CPG, low voltage components from Schneider.

MY1 Surface Paper Preheater

1)Diameter: 900mm / 1000m.

2)Working width: 1400-2000mm.

3)The heating area uses electrical adjustment.

4)The preheater uses national standard pressure vessel with an inspection certificate.

5)Steam trap from Taiwan.

MY2 Surface Paper Preheater

1)Diameter: 900mm / 1000m.

2)Working width: 1400-2200mm.

3)The heating area uses electrical adjustment.

4)Heating cylinder run by electric motor.

5)The preheater uses national standard pressure vessel with an inspection certificate.

6)Steam trap from Taiwan.

XY1 Core Paper Preheater

1)Diameter: 900mm / 1000m.

2)Working width: 1400-2000mm.

3)Heating area uses electrical adjustment.

4)The preheater uses national standard pressure vessel with an inspection certificate.

5)Steam trap from Taiwan.

XY2 Core Paper Preheater

1)Diameter: 900mm / 1000m.

2)Working width: 1400-2200mm.

3)Heating area adopts electrical adjustment.

4)Heating cylinder run by the electric motor.

5)The preheater uses national standard pressure vessel with an inspection certificate.

6)Steam trap from Taiwan.

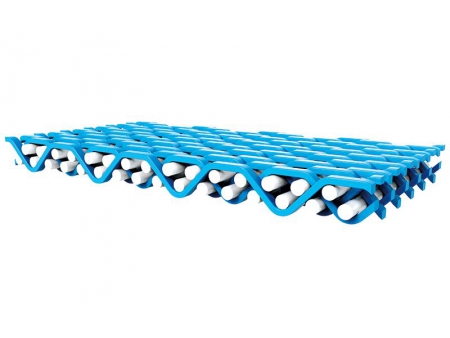

1) The conveyer feeds paper from the single face to the glue machine.

2) Main frame made of quality steel.

3) Guardrail adapted from Germany.

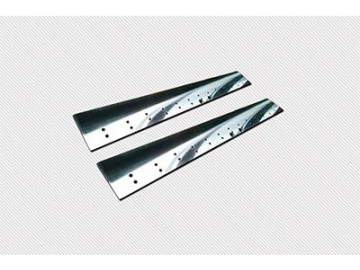

1)CNC machining ensures high precision.

2)Super thin blade separates paper, automatically or manually with a sharp knife.

3)Ball screw drives with high mechanical positioning and reliability.

4)Slitter speed uses an inverter motor with frequency conversion control, AC servo motor, and imported specialized driver.

5)Spiral knife made from long lasting material.

6)High precision gears.

1)Inverter and transmission belt speed automatically track speed.

2)Four section belts uses independent power to drive stacking at different speeds and lengths.

3)Pneumatic control and automatic counting separates batches.

Related names:

Cardboard making machine | Corrugated board slitter | Corrugated fiberboard making machine