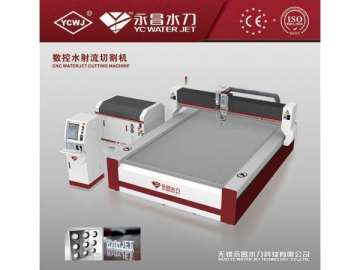

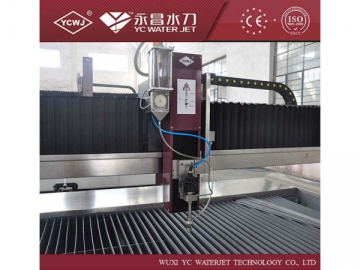

Full Set Water Jet Cutting Machine

This product has been discontinued and removed from our shelves.

Product Description

A high pressure water jet cutting machine is a tool used for slicing metal and other materials using a jet of water at high velocity and pressure. Featuring a low noise, no pollution, high precision and high reliability, our water jet cutting machine has been used in a variety of applications, including mining, automobile manufacturing, paper manufacturing, food, art and architecture. Water jet machines can be used to cut rubber, foam, plastic, composite, stone, tile, marble, glass and other materials.

Advantages of the water jet cutting machine

1.This water cutting machine can transfer between drawings and cutting quickly.

2.Fast positioning: the machine utilizes very few separable equipment pieces that potentially need to undergo repairs

3.High accuracy levels reduce the need for repeated cutting.

4.Faster cutting speed over similar products on the market today

5.There is no need to fabricate the working parts

6.As there is no pollution (i.e. dust, steam, fog), the cutting machine keeps the surrounding environment and operator safe

7.During the cutting process, no heat is produced

8.Clear processing: there is no need to clear working parts from the machine

9.Excellent cutting finishes: there is no need to rework cutting finishes after they are completed.

10.The water jet cutter features a narrow cutting gap

11.Quick and easy calibration and wider versatility in cutting: it has been proved that this machine can be used in mass production.

12.CAD/CAM software is compatible with this machine

13.The waterjet machine can cut nearly any material.

One complete machine set includes a CNC controller, a worktable, a pump, an abrasive delivery system, and a cooler. Optional components include a chiller waste removal system and a water softening unit.

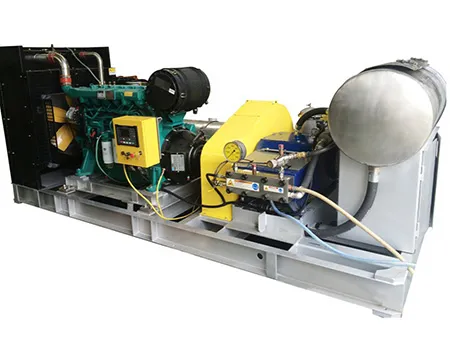

1. Waterjet High Pressure Pump

Control: PLC

Shifting: electro-hydraulic

Control Cooling: cooler/oil heat exchanger

Inlet water filter accuracy: ≤0.45μm

Oil-return filter accuracy: 20 μm

Working temp: 0-60°c

Outlet: UNF 3/8" Cooling in/out-let: NPT1" Max orifice size: 0.33mm

Hp System: YCWJ-3038 (semi-import configuration)

Max. Pressure: 380mpa

Max. Flowrate: 3.7L/min

Electrical power: 30KW

Voltage: 380VAC, 50HZ, 3PH (customized)

Some key parts use imported parts

Hp System: YCWJ-3742 (full-import configuration)

Max. Pressure: 420mpa

Max. Flowrate: 3.7L/min

Electrical power: 37KW

Voltage: 380VAC, 50HZ, 3PH (customized)

Intensifier assembly imported from Accustream USA

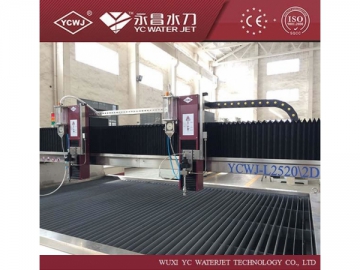

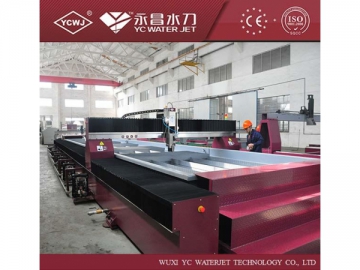

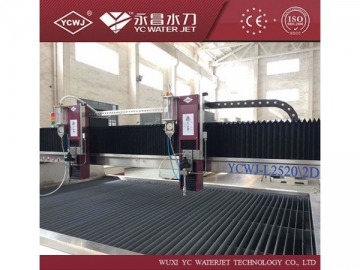

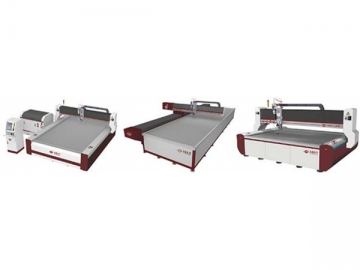

| Model(can be customed) | YCWJ-L2015 | YCWJ-L3020 | YCWJ-L4030 | YCWJ-X1520 | YCWJ-X1830 | |

| Machine type (L: Gantry, X: Cantilever) | Gantry | Gantry | Gantry | Cantilever | Cantilever | |

| Efficient cutting area(mm) | 2000*1500 | 3000*2000 | 4000*3000 | 1500*2000 | 1800*3000 | |

| Axis travel(mm) | X axis | 2000 | 3000 | 4000 | 1500 | 1800 |

| Y axis | 1500 | 2000 | 3000 | 2000 | 3000 | |

| Z axis | 150 | 150 | 150 | 150 | 150 | |

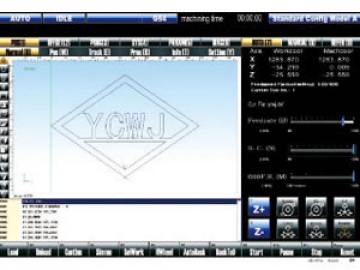

| CNC control system | Ac Servo motor | |||||

| Accuracy | Cutting accuracy | /- 0.1mm | ||||

| Repeat accurary | /- 0.05mm | |||||

| Processing speed | 0-15m/min | |||||

| Power supply | 240V/380V/415VAC, 3ph, 50Hz/60Hz(can be customed) | |||||

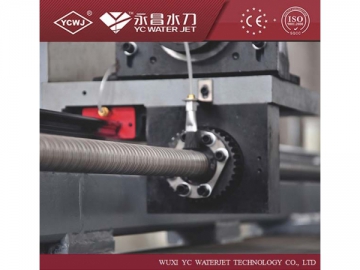

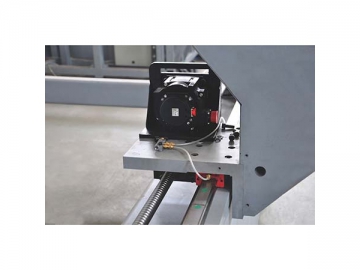

MITSUBISHI AC Servo motor and drive

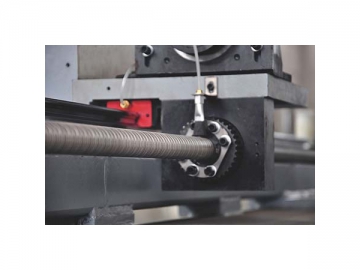

HIWIN or I F ball screw and guide rail

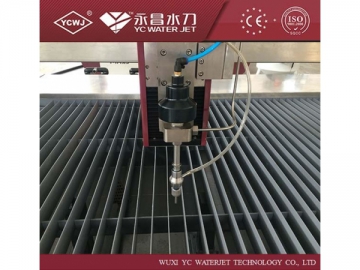

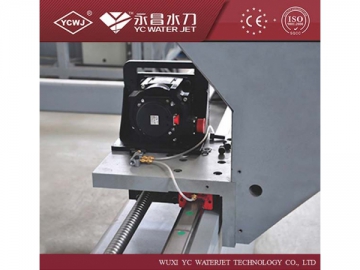

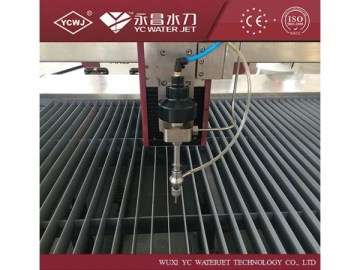

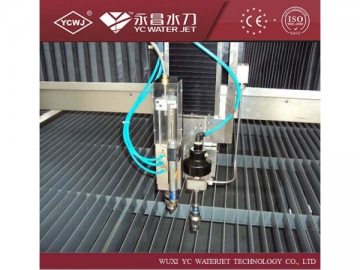

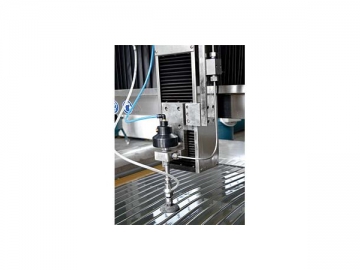

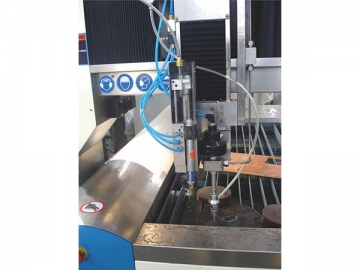

Cutting head

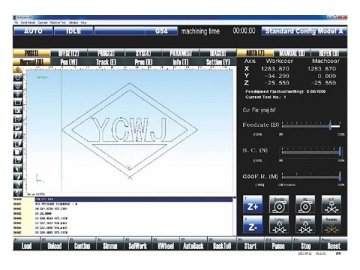

YC-NC9000A System

The waterjet automatic abrasive delivery system carries out the shoring and sanding for the machine, and as it is highly automatic, reduces labor levels.

Waterjet Auto Water Cooling Tower

We guarantee the hydraulic system can be used in a cicrcular manner and save water.

If your supplied water is hard water (CaCO3≥100mg/L), we would like to offer an optional machine that will soften your water.

2). Air cooled chiller

Applicable to tropical locations.

3). Cutting head with drilling function

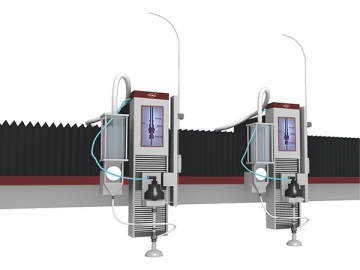

4). Multiple Cutting Heads

5). Auto sullage removal system

6). Fully Imported HP pump (such as KMT, Accustream/Hypertherm)

7). Italy ECS-905 CNC Controller

8. Our Service

One year guarantee:

1).We guarantee this machine is new, advanced technology and there are no defects in the materials or technology.

2).We ensure the technical data is input clearly and correctly. We also make sure it can satisfy the requests for installation debugging test operations and maintenance.

3).We will provide technical service and training on time.

4).This machine is YC’s intellectual property and is protected as such.

5).Maintenance is free during the warranty period, unless damage is found to be caused by customer error. If that is the case, clients are in charge of covering the cost.

6).Any costs incurred for repairing damage outside of the warranty period is to be covered by the client.

7).We have a supply of fittings on hand at all times.

8).Installation and training: Customers can come to be our factory, 4 to 5 days is all that is needed to learn how to correctly operate the waterjet cutting machine. We can also send technicians to customer locations for up to a week.

9.Payment

Payment terms: 30% of the total payment is due in advance. The rest must be paid off before delivery. T/T is accepted, as are other methods according to customer request.

Trade terms: FOB Shanghai, or customer request

10.Company information

YC Water Jet Technology Co., Ltd. is located in Wuxi City, about 150k away from downtown Shanghai. Founded in 1999 under the name of YC Industry, we have been manufacturing and selling a variety of top notch water jets for over 10 years. We specialize in the design, development and production of high pressure water jet cutting systems. Our machines are known for their smooth cutting process and precise controlling technology. Utilizing advantages from the United States, and the KMT Company’s high pressure pump technology, our water jet cutting machines are first class all over the world. Placing the most importance on trust and quality, our customer’s requests and creative base for market demands are what our company is made of and our commitment to our customers. High quality systems, low wear parts, and excellent customer services are what keeps our clients coming back, which is why YC’s low noise, pollution free high pressure water jet cutting systems are used in steel nonferrous metal, glass, stone, hard alloy, plastic, synthetic fiber cloth, paper, composite material and food material cutting.

Contact Me

In order to help you choose the best suitable machine, please try to reply my questions below, thanks for your cooperation.

Q1: What about your material?

Q2: The size of your processing material, length? Width and cutting thickness?

Related Names

Waterjet Cutting Machine | Water Jet Cutting Machine | CNC Water Jet Cutting Machine | Water Jet Cutting | Water Cutting Machine | Jet Cutting Machine | Marble Cutting Machine