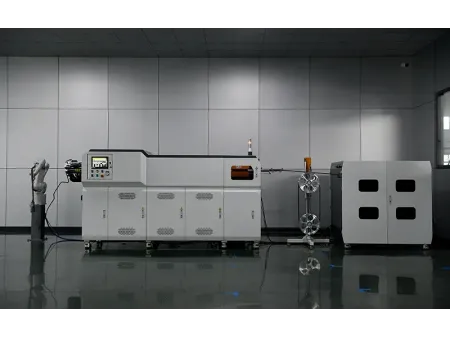

Plastic Tube Bending Machine (Tube Diameter 6-22mm)

S3000-22V

Traditional automotive tube thermoforming is a process that involves heating plastic tubes until they become pliable and then shaping them into specific configurations using molds. However, the 5th generation of nylon tube thermoforming machines represents a significant leap forward, eliminating the need for these costly and cumbersome metal molds. Building on the success of the previous generation, this updated tube bending machine offers enhanced efficiency and is designed for bending nylon and other plastic tubes commonly used in vehicle systems. With 5th generation tube bending equipment it is possible to manufacture automotive components such as coolant pipes, vacuum lines, fuel hoses, and brake air systems. This latest generation of automotive tube bending machinery allows for seamless production of larger-diameter and thin-walled tubes, meeting the demands of modern automotive design. Its advanced automation reduces manual handling, cutting down on production time and associated costs while ensuring consistency and high-quality results. The increased capabilities make it a valuable asset for manufacturers aiming to make automotive tube manufacturing more efficient and meet the evolving needs of automotive technologies.

- Tube Diameter: 6-22mm

- Usable Length: up to 5000mm

- Min. Bending Angle: 55°

- Right-Angle Production Rate: 3.5s/bend

- Max. Bends: 40

- Memory Capacity: 2000 job storage

- Tubes bending machines from this latest generation use an integrated digital control system to handle feeding, heating, bending, cooling, and forming, which significantly improves development speed, processing efficiency, and overall product quality

- Without the need for metal molds or labor-intensive, high-energy heating furnaces, these nylon pipes bending machines save both time and costs. Different bending requirements for nylon tubes can be easily programmed into the system, reducing manual input and improving product consistency while minimizing tube damage

- Unlike previous models, the fifth generation adopts dual feeding (front and back), with a front-feed servo motor that allows for higher precision in tube processing, achieving a tolerance of T1.5mm

- The ovality of the bends has been optimized, greatly improving fluid flow through the tubes. Plus, the tube bending machine’s fixed-length processing eliminates the need for secondary cutting, which helps reduce material waste

- Compared to traditional heating methods, this tube thermoforming system uses precise convection heating, reducing heating times by 90% (from 15-25 minutes to 1.5-2.5 minutes) and significantly lowering energy consumption

- It can handle a wide range of materials, including PA12, PA1012, PA612, PA66, PP, PE, and TPV, with the ability to process 90% of nylon tube types. It’s also capable of working with large-diameter and thin-walled tubes, increasing production efficiency by 22% compared to the previous generation

- The fifth generation of nylon tube bending machines complies with ENISO12100:2010 and EN60204-1:2018 standards, ensuring safety and reliability

- Optional features include robotic integration for tasks like spring insertion and tube marking, further enhancing the flexibility and automation of the production process

| Machine Color | White/industrial grey |

| Net Weight | 2100kg |

| Machine Size | 3800×1100×2050mm |

| Rated Power | 13kW |

| Heating Power | 8.5kw (peak value) |

| Air Consumption | 0.3-0.5m³/min |

| Power Consumption | 5.5kW.h |

| Right-Angle Production Rate | 3.5s/bend |

| Max. Bends | 40 |

| Max. Usable Length | 5000mm |

| Memory Capacity | 2000 job storage |

| Motor Power for Bending (Y axis) | 0.4kW (servo motor×1) |

| Motor Power for Rotation (Z axis) | 1.5kW (servo motor×1) |

| Motor Power for Back Feeding (X axis) | 0.4kW (servo motor×2) |

| Motor Power for Feeding (X axis) | 0.1kW (servo motor×2) |

| Motor Power for Lifting (Z axis) | 0.75kW (servo motor×1) |

| Model | | | |

| Machine Color | White/industrial grey | White/industrial grey | White/industrial grey |

| Net Weight | 2100kg | 2200kg | 1600kg |

| Machine Size | 3800×1100×2050mm | 4250×1100×1800mm | 4200×850×1750mm |

| Rated Power | 13kW | 13kW | 11kW |

| Heating Power | 8.5kW (peak value) | 8.5kW (peak value) | 8.5kW (peak value) |

| Air Consumption | 0.3-0.5m³/min | 0.3-0.5m³/min | 0.3-0.5m³/min |

| Power Consumption | 5.5Kw.h | 4.5Kw.h | 3Kw.h |

| Right-Angle Production Rate | 3.5s/bend | 4.5s/bend | 6.5s/bend |

| Max. Bends | 40 | 30 | 15 |

| Max. Usable Length | 5000mm | 1000mm | 800mm |

| Memory Capacity | 2000 group | 1000 group | 300 group |

| Motor Power for Bending (Y axis) | 0.4kW (servo motor×1) | 0.4kW (servo motor×1) | 0.4kW (servo motor×1) |

| Motor Power for Rotation (Z axis) | 1.5kW (servo motor×1) | 0.75kW (servo motor×1) | 0.75kW (servo motor×1) |

| Motor Power for Back Feeding (X axis) | 0.4kW (servo motor×2) | 0.4kW (servo motor×2) | 0.4kW (servo motor×2) |

| Motor Power for Feeding (X axis) | 0.1kW (servo motor×2) | / | / |

| Motor Power for Lifting (Z axis) | 0.75kW (servo motor×1) | 0.75kW (servo motor×1) | / |

- PA12/PA11 (single/multi-layer tube)

- PA1012, PA612, PA66, PP, PE, TPV

- PA12/PA11 (single/multi-layer tube)

- PA612, PA1012, PA6

- PA12/PA11 (single-layer tube)

- Tube size: 8×1

- Blank length of bend: 2650mm

- Bends: 15

- Process cycle: 72s

- Material: PA12/EVOH/PA12

- Bend radius: R20

- Flatness: >88%

- Tube size: 12×1

- Blank length of bend: 950mm

- Bends: 8

- Process cycle: 45s

- Material: PA612/EVOH/PA12

- Bend radius: R30

- Flatness: >88%

- Tube size: 12×1

- Blank length of bend: 1950mm

- Bends: 18

- Process cycle: 120s

- Material: PA12/EVOH/PP

- Bend radius: R30

- Flatness: >88%

- Tube size: 16×1.25

- Blank length of bend: 1250mm

- Bends: 11

- Process cycle: 75s

- Material: PA12/EVOH/PA12

- Bend radius: R20

- Flatness: >88%

- Tube size: 16×1.25

- Blank length of bend: 1350mm

- Bends: 10

- Process cycle: 65s

- Material: PA612/EVOH/PA12

- Bend radius: R40

- Flatness: >88%

- Tube size: 16×1.25

- Blank length of bend: 1650mm

- Bends: 13

- Process cycle: 92s

- Material: PA12

- Bend radius: R40

- Flatness: >88%

- Tube size: 16×1.25

- Blank length of bend: 650mm

- Bends: 3

- Process cycle: 22s

- Material: PA612

- Bend radius: R40

- Flatness: >88%

For multiple products with the same tube diameter, only the pipe decoiler needs to be prepared. There’s no need for pre-cutting or organizing tubes based on different product drawings or order volumes. This eliminates the manual cutting process, storage categorization, and additional management tasks. The thermoforming machine automatically cuts the tubes to the programmed length, removing the need for secondary cuts and reducing material waste

(No Mold & Tooling Required)

Eliminates the need for metal molds, reducing costs associated with mold investment, storage, and management. This advancement significantly shortens the development cycle for new products by simplifying the setup process and enabling rapid prototyping and adjustments through the digital interface.

Does not require pre-heating, streamlining the production process and cutting manufacturing costs. By eliminating the pre-heating stage, the tube thermoforming machine enhances operational efficiency and reduces energy consumption

The heating system removes the need for individual drying ovens, significantly lowering energy usage and reducing the required operational footprint. By employing a 360-degree convection heating method, the tubes are heated uniformly and precisely, which greatly improves production efficiency and ensures consistent product quality

Reduces energy consumption and investment in machinery, minimizes space requirements, and enhances production efficiency and product quality. By using digitally controlled air flow, the system precisely manages the cooling rate, which is crucial for maintaining the integrity and uniformity of the finished products

Reduces material waste significantly by ensuring precise and efficient cutting

Digitally controlled uniform heating ensures even processing, and after cooling, the material is cut to precise, predetermined lengths. This enhances product consistency, ensuring every item meets quality standards, while also significantly reducing material waste.

The quality of the tube's appearance is substantially improved through digitally controlled bending. This system precisely regulates the flattening rate using bending dies and internal springs, resulting in minimal deformation. The reduced flattening allows for a greater airflow within the same timeframe, thus enhancing the tube's operational performance and reliability

| Tube Size | Min. Bend Radius | Shortest Straight Line between Two Right Angles | Min. Included Angle |

| 6×1 | 15 | 25 | 55 |

| 8×1 | 20 | 30 | 55 |

| 10×1 | 25 | 30 | 55 |

| 10×1.25 | 25 | 30 | 55 |

| 12×1 | 28 | 30 | 60 |

| 12×1.25 | 28 | 30 | 60 |

| 12×1.5 | 28 | 30 | 60 |

| 12.5×1.5 | 30 | 28 | 60 |

| 13.5×1.25 | 30 | 28 | 60 |

| 14×1.5 | 30 | 27 | 60 |

| 14×2 | 30 | 27 | 60 |

| 15×1.5 | 30 | 25 | 60 |

| 15×1.25 | 30 | 25 | 60 |

| 16×1.25 | 30 | 25 | 60 |

| 16×1.5 | 30 | 25 | 60 |

| 16×2 | 30 | 25 | 60 |

| 18×1.5 | 35 | 27 | 60 |

| 19×1.5 | 35 | 27 | 65 |

| 20×1.5 | 35 | 28 | 65 |

| 21×1.5 | 37 | 30 | 65 |

| 22×1.5 | 39 | 30 | 65 |

| Model | S3000-22V | BST25-IV | BST16-IIIS | ||||||

| Tube Size | Min. Bend Radius | Shortest Straight Line between Two Right Angles | Min. Included Angle | Min. Bend Radius | Shortest Straight Line between Two Right Angles | Min. Included Angle | Min. Bend Radius | Shortest Straight Line between Two Right Angles | Min. Included Angle |

| 6×1 | 15 | 25 | 55 | 15 | 25 | 80 | 22 | 30 | 85 |

| 8×1 | 20 | 30 | 55 | 20 | 30 | 80 | 25 | 35 | 85 |

| 10×1 | 25 | 30 | 55 | 25 | 35 | 80 | / | / | / |

| 10×1.25 | 25 | 30 | 55 | 25 | 35 | 80 | 25 | 40 | 85 |

| 12×1 | 28 | 30 | 60 | / | / | / | / | / | / |

| 12×1.25 | 28 | 30 | 60 | 30 | 40 | 80 | / | / | / |

| 12×1.5 | 28 | 30 | 60 | 30 | 40 | 80 | 35 | 45 | 85 |

| 12.5×1.5 | 30 | 28 | 60 | 30 | 40 | 80 | 35 | 45 | 85 |

| 13.5×1.25 | 30 | 28 | 60 | / | / | / | / | / | / |

| 14×1.5 | 30 | 27 | 60 | 35 | 45 | 80 | / | / | / |

| 14×2 | 30 | 27 | 60 | 35 | 45 | 80 | / | / | / |

| 15×1.5 | 30 | 25 | 60 | / | / | / | / | / | / |

| 15×1.25 | 30 | 25 | 60 | / | / | / | / | / | / |

| 16×1.25 | 30 | 25 | 60 | / | / | / | / | / | / |

| 16×1.5 | 30 | 25 | 60 | / | / | / | / | / | / |

| 16×2 | 30 | 25 | 60 | / | / | / | / | / | / |

| 18×1.5 | 35 | 27 | 60 | / | / | / | / | / | / |

| 19×1.5 | 35 | 27 | 65 | / | / | / | / | / | / |

| 20×1.5 | 35 | 28 | 65 | / | / | / | / | / | / |

| 21×1.5 | 37 | 30 | 65 | / | / | / | / | / | / |

| 22×1.5 | 39 | 30 | 65 | / | / | / | / | / | / |

- Heating system:Double variable frequency control

- Heating method:Full convection heating

- Programmable coordinate editing:Supported

- Human machine interface (HMI):High-level configuration

- Feeding control:Electric control

- Feeding method:Forth feeding and back feeding

- Processing accuracy:T1.5mm

- Compatibility with robot:Supported

- Servo control:Optical fiber BUS

- Handwheel control:Available

- Optional laser marking:Available

- Production statistics:Available

- One-key reset:Available

- Machine status monitoring:Available

- On-Site engineer support: Engineers from our team are ready to provide on-site installation and fine-tuning

- Remote engineer training: We provide comprehensive remote training to empower client engineers with the knowledge to operate our equipment

- Remote monitoring system: We offer remote monitoring systems that allow operational oversight and troubleshooting. (Available with custom-configured models.)

- Warranty and long-term service: Each tube bending machine comes with a one-year warranty and lifetime service, ensuring our clients receive ongoing support