Plastic Tube Bending Machine (Tube Diameter 6-12mm)

BST16-IIIS

The 3rd generation nylon tube bending machine has been widely applied in processing single-layer PA11 and PA12 tubes for automotive uses. It features a fixed-frequency single-control heating system that operates at 8.5 kW, offering significant energy savings compared to traditional high-temperature forming methods. This pipe bending equipment removes the need for pre-shaping and mold setups, streamlining production by reducing time and associated costs. Capable of handling various tube shapes on a single machine, it provides flexibility for different nylon tube bending requirements. The production cycle, traditionally lasting up to 30 minutes, has been shortened to under 2 minutes, enhancing efficiency through improved heating and cooling processes.

- Tube Diameter: 6-12mm

- Usable Length: up to 800mm

- Min. Bending Angle: 85°

- Right-Angle Production Rate: 6.5s/bend

- Max. Bends: 15

- Memory Capacity: 300 job storage

- The bending system allows you to edit and adjust bending requirements directly, eliminating the need for mold changes or extra setups. This enhances flexibility and reduces downtime in production

- With the ability to process tube lengths up to 1000mm, this equipment meets the demands of most tube processing tasks, offering versatility for different projects

- Designed to handle tube diameters ranging from Ø6mm to Ø16mm, making it suitable for a variety of tube sizes used in industrial and automotive applications

- The right-angle bending speed reaches 6.5 seconds per bend, which significantly improves efficiency, especially in high-volume production environments

- Complies with ENISO12100:2010 and EN60204-1:2018 standards, ensuring both safety and reliability in operation

- Capable of being upgraded to incorporate the latest technological advancements, allowing the machine to evolve as production needs change

| Machine Color | White/industrial grey |

| Net Weight | 1600kg |

| Machine Size | 4200×850×1750mm |

| Rated Power | 11kW |

| Heating Power | 8.5kW (peak value) |

| Air Consumption | 0.3-0.5m³/min |

| Power Consumption | 3kW.h |

| Right-Angle Production Rate | 6.5s/bend |

| Max. Bends | 15 |

| Max. Usable Length | 800mm |

| Memory Capacity | 300 job storage |

| Motor Power for Bending (Y axis) | 0.4kW (servo motor×1) |

| Motor Power for Rotation (Z axis) | 0.75kW (servo motor×1) |

| Motor Power for Back Feeding (X axis) | 0.4kW (servo motor×2) |

| Model | | | |

| Machine Color | White/industrial grey | White/industrial grey | White/industrial grey |

| Net Weight | 2100kg | 2200kg | 1600kg |

| Machine Size | 3800×1100×2050mm | 4250×1100×1800mm | 4200×850×1750mm |

| Rated Power | 13kW | 13kW | 11kW |

| Heating Power | 8.5kW (peak value) | 8.5kW (peak value) | 8.5kW (peak value) |

| Air Consumption | 0.3-0.5m³/min | 0.3-0.5m³/min | 0.3-0.5m³/min |

| Power Consumption | 5.5Kw.h | 4.5Kw.h | 3Kw.h |

| Right-Angle Production Rate | 3.5s/bend | 4.5s/bend | 6.5s/bend |

| Max. Bends | 40 | 30 | 15 |

| Max. Usable Length | 5000mm | 1000mm | 800mm |

| Memory Capacity | 2000 group | 1000 group | 300 group |

| Motor Power for Bending (Y axis) | 0.4kW (servo motor×1) | 0.4kW (servo motor×1) | 0.4kW (servo motor×1) |

| Motor Power for Rotation (Z axis) | 1.5kW (servo motor×1) | 0.75kW (servo motor×1) | 0.75kW (servo motor×1) |

| Motor Power for Back Feeding (X axis) | 0.4kW (servo motor×2) | 0.4kW (servo motor×2) | 0.4kW (servo motor×2) |

| Motor Power for Feeding (X axis) | 0.1kW (servo motor×2) | / | / |

| Motor Power for Lifting (Z axis) | 0.75kW (servo motor×1) | 0.75kW (servo motor×1) | / |

- PA12/PA11 (single-layer tube)

- PA12/PA11 (single/multi-layer tube)

- PA1012, PA612, PA66, PP, PE, TPV

- PA12/PA11 (single/multi-layer tube)

- PA612, PA1012, PA6

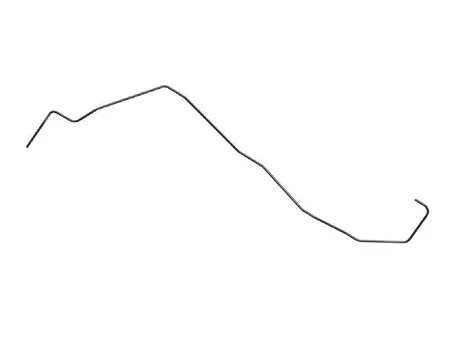

- Tube size: 8×1

- Blank length of bend: 2650mm

- Bends: 15

- Process cycle: 72s

- Material: PA12/EVOH/PA12

- Bend radius: R20

- Flatness: >88%

- Tube size: 12×1

- Blank length of bend: 950mm

- Bends: 8

- Process cycle: 45s

- Material: PA612/EVOH/PA12

- Bend radius: R30

- Flatness: >88%

- Tube size: 12×1

- Blank length of bend: 1950mm

- Bends: 18

- Process cycle: 120s

- Material: PA12/EVOH/PP

- Bend radius: R30

- Flatness: >88%

- Tube size: 16×1.25

- Blank length of bend: 1250mm

- Bends: 11

- Process cycle: 75s

- Material: PA12/EVOH/PA12

- Bend radius: R20

- Flatness: >88%

- Tube size: 16×1.25

- Blank length of bend: 1350mm

- Bends: 10

- Process cycle: 65s

- Material: PA612/EVOH/PA12

- Bend radius: R40

- Flatness: >88%

- Tube size: 16×1.25

- Blank length of bend: 1650mm

- Bends: 13

- Process cycle: 92s

- Material: PA12

- Bend radius: R40

- Flatness: >88%

- Tube size: 16×1.25

- Blank length of bend: 650mm

- Bends: 3

- Process cycle: 22s

- Material: PA612

- Bend radius: R40

- Flatness: >88%

| Tube Size | Min. Bend Radius | Shortest Straight Line between Two Right Angles | Min. Included Angle |

| 6×1 | 22 | 30 | 85 |

| 8×1 | 25 | 35 | 85 |

| 10×1.25 | 25 | 40 | 85 |

| 12×1.5 | 35 | 45 | 85 |

| 12.5×1.5 | 35 | 45 | 85 |

| Model | S3000-22V | BST25-IV | BST16-IIIS | ||||||

| Tube Size | Min. Bend Radius | Shortest Straight Line between Two Right Angles | Min. Included Angle | Min. Bend Radius | Shortest Straight Line between Two Right Angles | Min. Included Angle | Min. Bend Radius | Shortest Straight Line between Two Right Angles | Min. Included Angle |

| 6×1 | 15 | 25 | 55 | 15 | 25 | 80 | 22 | 30 | 85 |

| 8×1 | 20 | 30 | 55 | 20 | 30 | 80 | 25 | 35 | 85 |

| 10×1 | 25 | 30 | 55 | 25 | 35 | 80 | / | / | / |

| 10×1.25 | 25 | 30 | 55 | 25 | 35 | 80 | 25 | 40 | 85 |

| 12×1 | 28 | 30 | 60 | / | / | / | / | / | / |

| 12×1.25 | 28 | 30 | 60 | 30 | 40 | 80 | / | / | / |

| 12×1.5 | 28 | 30 | 60 | 30 | 40 | 80 | 35 | 45 | 85 |

| 12.5×1.5 | 30 | 28 | 60 | 30 | 40 | 80 | 35 | 45 | 85 |

| 13.5×1.25 | 30 | 28 | 60 | / | / | / | / | / | / |

| 14×1.5 | 30 | 27 | 60 | 35 | 45 | 80 | / | / | / |

| 14×2 | 30 | 27 | 60 | 35 | 45 | 80 | / | / | / |

| 15×1.5 | 30 | 25 | 60 | / | / | / | / | / | / |

| 15×1.25 | 30 | 25 | 60 | / | / | / | / | / | / |

| 16×1.25 | 30 | 25 | 60 | / | / | / | / | / | / |

| 16×1.5 | 30 | 25 | 60 | / | / | / | / | / | / |

| 16×2 | 30 | 25 | 60 | / | / | / | / | / | / |

| 18×1.5 | 35 | 27 | 60 | / | / | / | / | / | / |

| 19×1.5 | 35 | 27 | 65 | / | / | / | / | / | / |

| 20×1.5 | 35 | 28 | 65 | / | / | / | / | / | / |

| 21×1.5 | 37 | 30 | 65 | / | / | / | / | / | / |

| 22×1.5 | 39 | 30 | 65 | / | / | / | / | / | / |

- Heating system:Single fixed frequency control

- Heating method:Semi-convection heating

- Programmable coordinate editing:Not supported

- Human machine interface (HMI):Low-level configuration

- Feeding control:Pneumatic control

- Feeding method:Back feeding

- Processing accuracy:T3mm

- Compatibility with robot:Not supported

- Servo control:Pulse

- Handwheel control:Non-available

- Optional laser marking:Non-available

- Production statistics:Non-available

- One-key reset:Non-available

- Machine status monitoring:Non-available