White Fused Alumina

White fused alumina is produced from high-quality aluminum oxide powder, refined and crystallized through electric arc smelting. It features high purity, excellent self-sharpening properties, resistance to acid and alkali corrosion, high-temperature stability, and stable thermal performance. It is slightly harder than brown fused alumina but less tough. With strong grinding capabilities, low heat generation, and high efficiency, it is suitable for making abrasive tools used for grinding high-carbon steel, high-speed steel, and stainless steel. Fine-grit abrasives can also be used in precision casting and high-grade refractory materials.

Available Grain Sizes

| Fraction | 0-1mm 1-3mm 3-5mm 5-8mm | |

|---|---|---|

| Fine Powder | 200#-0 320#-0 | |

| Grit | 8# 12# 14# 16# 20# 24# 30# 36# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# 240# | |

| Micro Powder | JIS Standard | #240 #280 #320 #360 #400# #500 #600 #700 #800 #1000 #1200 #1500 #2000 #2500 #3000 #4000 #6000 #8000 #10000 |

| FEPA Standard | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 | |

Typical Chemical Analysis

| Grain Size | Chemical Composition (%) | |||

|---|---|---|---|---|

| Al2O3 | Fe2O3 | Na2O | SiO2 | |

| Fraction | ≥99 | ≤0.08 | ≤0.35 | ≤0.08 |

| Fine Powder | ≥98.5 | ≤0.15 | ≤0.40 | ≤0.08 |

| Grit | ≥99 | ≤0.1 | ≤0.35 | ≤0.08 |

| Micro Powder | ≥98 | ≤0.1 | ≤0.40 | ≤0.08 |

Typical Physical Properties

| Mohs Hardness | 9.0 |

|---|---|

| Bulk Density | 1.55-1.95g/cm3 |

| True Density | 3.95g/cm3 |

| Volume Density | 3.60 |

| Melting Point | 2250℃ |

| Maximum Use Temperature | 1900℃ |

Applications

- White fused alumina is widely used in various industrial fields due to its high hardness, toughness, and excellent thermal stability. Common application areas include:

- Cutting and grinding: Used for manufacturing cutting and grinding tools, such as grinding wheels and sanding belts.

- Polishing: Suitable for polishing various materials, including metals, glass, and ceramics.

- Abrasive media: Used as abrasive media in applications like petroleum industry abrasives.

- Refractory materials: Ideal for producing high-temperature refractory materials, such as kiln linings and crucibles.

- Precision casting: Used in precision casting sand and core sand to improve casting accuracy and surface quality.

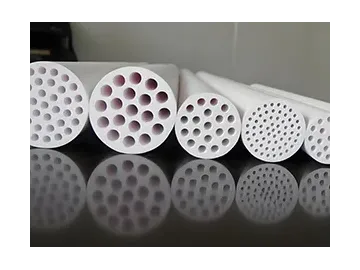

- Ceramic membranes

- Grinding wheels

- Floor coatings

- Sandblasting abrasives

- Refractories

Manufacturing Process

White fused alumina is commonly prepared using several methods, with the ball milling method being one of the most prevalent. In the ball milling process, raw materials are mixed with milling media (such as glass or steel balls) and ground under high-speed rotation. Another method is the electric fusion process. In this method, raw materials are placed in an electric furnace, melted at high temperatures, and then cooled and crushed to produce white fused alumina.

Packaging

- 25kg packaging

- 25kg small bag bulk bag

- 25kg small bag pallet wrap