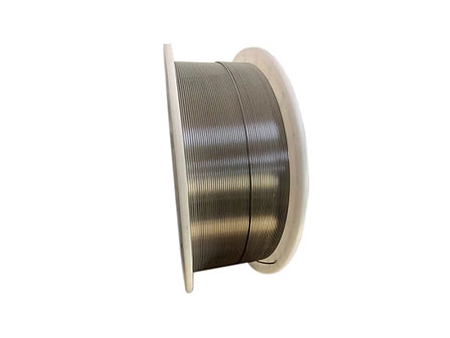

Alloy 622 Nickel Alloy Welding Wire

Alloy 622 nickel alloy welding wire (ERNiCrMo-10) is used for welding alloys with similar compositions and for joining nickel-chromium-molybdenum alloys to stainless steel or low-alloy steel. Thanks to its outstanding resistance to oxidation and reducing environments, as well as its superior resistance to stress corrosion cracking, pitting, and crevice corrosion, this alloy is widely chosen for cladding applications.

Common Names: Oxford Alloy® 622, FM 622, Techalloy 622

Standards: AWS A5.14, ERNiCrMo-10, ASME IX, F-No. 43, UNS N06022, ISO SNi6022, European NiCr21Mo13FeW3

Chemical composition (%)| C | Si | Mn | S | P | Ni | Cr |

| ≤0.015 | ≤0.08 | ≤0.5 | ≤0.01 | ≤0.02 | Rest | 20-22.5 |

| V | W | Fe | Cu | Mo | Co | Others |

| ≤0.35 | 2.5-3.5 | 2.0-6.0 | ≤0.5 | 12.5-14.5 | ≤2.5 | ≤0.5 |

| Process | Diameter | Voltage | Amperage | Gas |

| TIG | .035” (0.9mm) .045” (1.2mm) 1/16” (1.6mm) 3/32” (2.4mm) 1/8” (3.2mm) | 12-15 13-16 14-18 15-20 15-20 | 60-90 80-110 90-130 120-175 150-220 | 100% Argon 100% Argon 100% Argon 100% Argon 100% Argon |

| MIG | .035” (0.9mm) .045” (1.2mm) 1/16” (1.6mm) | 26-29 28-32 29-33 | 150-190 180-220 200-250 | 75% Argon 25% Helium 75% Argon 25% Helium 75% Argon 25% Helium |

| SAW | 3/32” (2.4mm) 1/8” (3.2mm) 5/32” (4.0mm) | 28-30 29-32 30-33 | 275-350 350-450 400-550 | Can be used with appropriate flux Can be used with appropriate flux Can be used with appropriate flux |

| Tensile strength | 115,000 PSI | 790 MPA |

| Yield strength | 82,000 PSI | 570MPA |

| Elongation | 38% |

Application

Suitable for welding nickel-chromium-molybdenum-based materials, steel, and other nickel alloys, as well as for overlay welding on steel. It is also used for welding duplex and super duplex stainless steels.