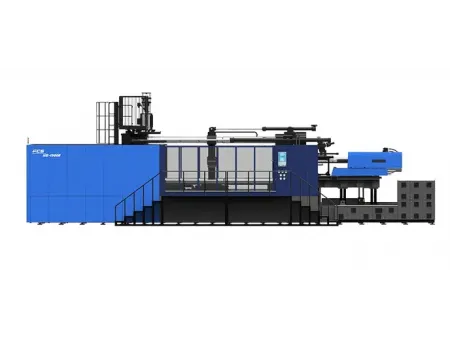

Large Rotary Table Two-Component Injection Molding Machine

This innovative large rotary table two-component injection molding machine is designed specifically for producing extensive plastic parts. By incorporating a horizontal rotary table, it effectively mitigates the issues of traditional inertia and gravity impacts during molding. The system supports dual mold stacking for simultaneous output, employing quad-face mold configurations and external cooling structures to boost production capacity. With clamping forces ranging from 350 to 3500 tons, this injection molding equipment is engineered to enhance output while maintaining precise control over large-scale production processes.

- Injection stroke: 280mm-540mm

- Injection capacity: 583g-4668g

- Injection pressure: 2008kgf/cm²-2497kgf/cm²

- Injection rate: 196g/s-994g/s

- Clamping force: 350tonf-3500tonf

- Clamping stroke: 1600mm-4950mm

- Pump motor power: 30.7kW-135kW

- Electric heating power: 19.86kW-40.92kW

- Drive system: hydraulic/hybrid

The two-color injection molding machine is suitable for the production of car sunroof shade, lamp housing, plastic housing and panel for home appliance, etc.

- Two-Color Tail Light

- Tri-Color Tail Light

- Plastic Pallet

- Injection molding of car light

- Trial injection molding of TV bezel

These units ensure stable and precise injection, offering customizable specifications to suit varying production needs.

Provide symmetrical and steady clamping force, with a high-pressure lock mold system that simplifies force settings and enhances the molding machine’s longevity.

This power-saving feature cuts energy consumption by over 40%, underscoring the injection molding system's commitment to environmental sustainability.

Integrates Statistical Process Control (SPC) and remote monitoring to optimize production and management efficiency while incorporating mold protection features to extend the molds life.

- Its dual-colored injection capabilities could applicable for both single and double component products to increase machine capabilities.

- A horizontal rotary platen decreases issues coming from gravity and inertia.

- Its swivel unit provides quick positioning and is equipped with numerous safety features.

- High loading capacity and self-supporting swivel unit to hold a maximum mold weight of up to 30 tons. Suitable for two-colored, large products like automotive exterior components.

- A special process integration, such as a special four-sided mold, can form a stack mold.