Dispersing Machine

Request a Quote

Powder processing equipment for the production of battery anode materials

- Designed to depolymerize and restore oversize materials after graphitization and carbonization, specifically for battery anode production

- The innovative design ensures a high particle restoration rate without damaging the original shape, significantly improving tap density

- High classification precision with minimal over-grinding, offering accurate cut points that restore the original particle size without increasing fine powder content in the final product

- Offers large processing capacity and low energy consumption, providing significant advantages over other dispersing machines in terms of efficiency, space, and overall production costs

- Reliable mechanical and flow field design supports 24-hour continuous production with stable quality, making it ideal for high-volume, high-quality material production. The wear parts have a long lifespan

- Built to last, the equipment is made with materials tested for fatigue strength, ensuring a finely crafted machine with a lifespan of over 20 years

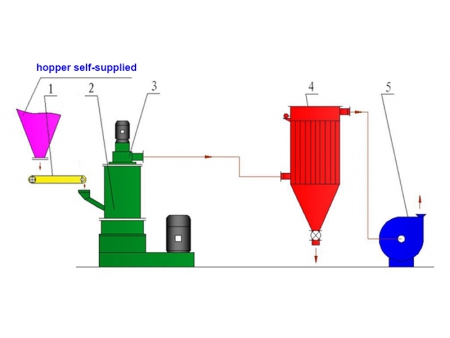

Process Flow

1. Material feeder

2. Grinding system

3. Classifying system

4. Bag filter

5. Draft fan