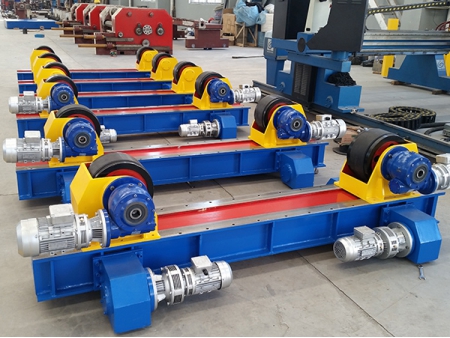

Casing Rotator

The casing rotator is a kind of newly developed drilling equipment integrating the advantage of hydraulic power system and transmission device. It is controlled by mechanical, electrical and hydraulic system, featuring environmental protection and high efficiency.

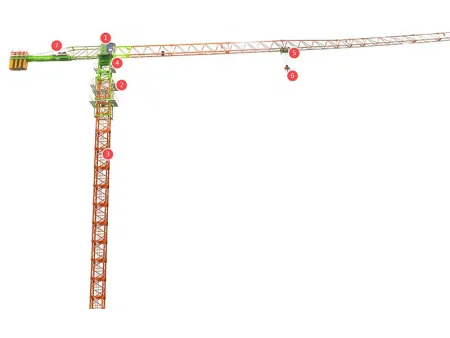

In recent years, our rotary drilling rig is widely used in subway construction, secant piling for foundation pit protection, discarded pile (underground obstacle) clearance, as well as high speed rail, road, bridge, and urban construction. In addition, our casing rotator is an ideal tool for reservoir dam reinforcement. Here is the specific introduction for the applications.

1. Foundation pile and diaphragm wall construction

1) Foundation piles for high-speed rail, road, bridge, and house construction.

2) Secant piling for subway platform, underground building, diaphragm wall, and other construction requiring heavy excavation.

3) Reservoir retention wall reinforcement.

2. Cobble stone, boulders and karst cave drilling

1) It supports foundation pile construction in the mountain land with cobble stone and boulder.

2) Application at coastal region is allowed, where it features thick quicksand and hole shrinkage, for foundation pile construction.

3) The piling equipment can be used for socket pile construction, also.

3. Underground obstructions clearance

In the process of urban construction and bridge reconstruction, our casing rotator can be employed for cleaning reinforced concrete pile, steel-pipe pile, steel H pile, PC pile, wooden pile, and some others, realizing foundation pile poured-in-place.

4. Rock stratum drilling

1) Rock socketed drilling for pile poured-in-place

2) Through-hole drilling on sill for vertical shaft or ventilation hole

5. Deep excavation

1) Poured-in-place for steel-pipe pile insertion for deep foundation improvement

2) Deep well digging for the construction of reservoir and tunnel

Advantages

1. Aside from little noise and vibration, our casing rotator has high safety.

2. Requiring little mud, the construction site is clean. In addition to environmental protection, it prevents mud entering into concrete for high quality pile formation, which is conducive to the improvement of the concrete bond stress to rebar.

3. During construction, workers can determine the stratum and rock character, intuitively.

4. For regular soil layer, the drilling speed of the casing rotator reaches up to 14m/hour.

5. According to soil layer condition, the maximum drilling depth can be as high as 80m.

6. It is easy for operator to understand the hole perpendicularity, which can be accurate to 1/500.

7. Hole collapse can be avoided, achieving high drilling quality.

8. Compared with other hole drilling method, our product drills holes with standard diameter and small concrete filling coefficient.

9. Our drilling machine is distinguished by complete and speedy hole cleaning. The drilling waste at the hole bottom is no more than 3cm.

| Model: TR1305L | |||

| Working Device | Hole Dia. | mm | Φ600-Φ1300 |

| Rotary Torque | KN.m | 1770/1050/590 | |

| Revolving Speed | rpm | 1.5/2.6/4.5 | |

| Sleeve Downforce | KN | Max.360 plus dead weight 190 | |

| Max. Pulling Force of Sleeve | KN | 2690 | |

| Operating Stroke | mm | 500 | |

| Weight | ton | 25 | |

| Hydraulic Power Unit | Engine Model | - | Y2-280M-4 |

| Engine Power | kW/rpm | 2×90/1480 | |

| Weight | ton | 4 | |

| Control Mode | - | Wired remote control | |

| Model: TR1505 | |||

| Working Device | Hole Dia. | mm | Φ800-Φ1500 |

| Rotary Torque | KN.m | 1500/975/600 (Instantaneous torque: 1800) | |

| Revolving Speed | rpm | 1.6/2.46/4.0 | |

| Sleeve Downforce | KN | Max.360 plus dead weight 210 | |

| Max. Pulling Force of Sleeve | KN | 2444 (Instantaneous pulling force: 2690) | |

| Operating Stroke | mm | 750 | |

| Weight | ton | 31+7(Optional track) | |

| Hydraulic Power Unit | Engine Model | - | ISUZU AA-6HK1XQP |

| Engine Power | kW/rpm | 183.9/2000 | |

| Fuel Consumption | g/kwh | 226.6(For max. power) | |

| Weight | ton | 7 | |

| Control Mode | - | Wired remote control | |

| Model: TR2005H Casing Rotator | |||

| Working Device | Hole Dia. | mm | Φ1000-Φ2000 |

| Rotary Torque | KN.m | 2965/1752/990 (Instantaneous torque: 3391) | |

| Revolving Speed | rpm | 1.0/1.7/2.9 | |

| Sleeve Downforce | KN | Max.600 plus dead weight 260 | |

| Max. Pulling Force of Sleeve | KN | 3760 (Instantaneous pulling force: 4300) | |

| Operating Stroke | mm | 750 | |

| Weight | ton | 45+9 (Optional track) | |

| Hydraulic Power Unit | Engine Model | - | Cummins QSM11-335 |

| Engine Power | kW/rpm | 272/1800 | |

| Fuel Consumption | g/kwh | 216 (For max. power) | |

| Weight | ton | 8+0.3 (Optional road wheel) | |

| Control Mode | - | Wired remote control | |

| Model: TR2605H | |||

| Working Device | Hole Dia. | mm | Φ1200-Φ2600 |

| Rotary Torque | KN.m | 5292/3127/1766 (Instantaneous torque: 6174) | |

| Revolving Speed | rpm | 0.6/1.0/1.8 | |

| Sleeve Downforce | KN | Max.830 plus dead weight 350 | |

| Max. Pulling Force of Sleeve | KN | 3800 (Instantaneous pulling force: 4340) | |

| Operating Stroke | mm | 750 | |

| Weight | ton | 55+10 (Optional track) | |

| Hydraulic Power Unit | Engine Model | - | Cummins QSM15-600 |

| Engine Power | kW/rpm | 441/1800 | |

| Fuel Consumption | g/kwh | 213 (For max. power) | |

| Weight | ton | 12 | |

| Control Mode | - | Wired remote control | |

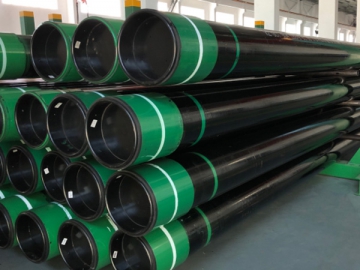

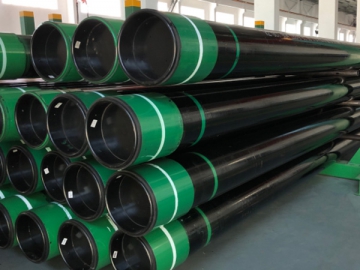

Impact grab bucket, casing rotator, heavy hammer, foundation pile, continuous wall, drilling gravels, boulders and karst caves, clear the underground obstructions, cut the rock stratum, deep excavation, Secant pile wall