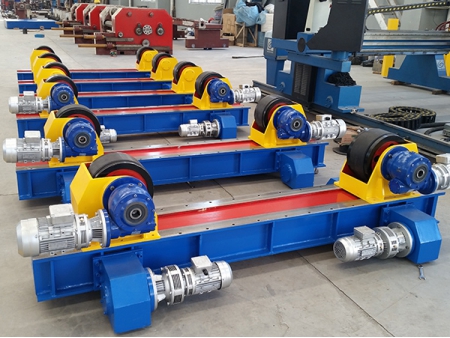

Welding Rotator

Engineered for adaptability across various product diameters, our conventional welding rotators offer stepless speed adjustments for seamless welding processes. Designed with noise reduction in mind, these welders operate with minimal sound, ensuring a quiet work environment while delivering smooth and steady rotation. One of the main features of this welding equipment, is the incorporation of polyurethane wheels, a superior organic polymer that outmatches standard rubber in oil resistance, toughness, wear resistance, and aging resistance. Polyurethane's impressive performance offers 3-5 times higher tensile, tear, and abrasion resistance, making metal supports unnecessary. This makes our rotators particularly suited for wind tower production lines and the welding of stainless-steel cylinders.

These welding rotators are mainly used in the production of wind towers and the welding of stainless steel cylinders, showcasing their significant role in modern manufacturing processes.

- Variable speed control: Allows for precise speed adjustments to match project requirements.

- Low noise operation: Designed to minimize noise for a more comfortable working environment.

- Stable rotation: Ensures consistent welding quality by maintaining stability throughout the process.

| Model | Max. load carrying capacity (kg) | Range of suitable workpiece (mm) | Wheel size (diameter × width) (mm) | Wheel speed (m/h) | Motor (kW) | |

| Rubber rollers | Metal rollers | |||||

| | 3000 | Ø250~Ø1800 | Ø200×100 | 2XØ194×20 | 8-60 | 2×0.25 |

| | 5000 | Ø250~Ø2300 | Ø250×100 | 2XØ240×20 | 6~60 | 2×0.37 |

| | 10000 | Ø320~Ø2800 | Ø300×120 | 2XØ290×25 | 6~60 | 2×0.55 |

| | 20000 | Ø500~Ø3500 | Ø350×120 | 2XØ340×30 | 6~60 | 2×1.1 |

| | 40000 | Ø600~Ø4200 | Ø400×120 | 2XØ390×40 | 6~60 | 2×1.5 |

| | 60000 | Ø750~Ø4800 | Ø450×120 | 2×Ø440×50 | 6~60 | 2×2.2 |

| | 80000 | Ø850~Ø5000 | Ø500×120 | 2×Ø490×60 | 6~60 | 2×3 |

| | 100000 | Ø1000~Ø5500 | Ø500×120 | 2XØ490×70 | 6~60 | 2×3 |

| | 180000 | Ø1100~Ø6000 | ---- | Ø620×220 | 6~60 | 2×4 |

| | 250000 | Ø1200~Ø7000 | ---- | Ø700×280 | 6~80 | 2×5.5 |

| | 500000 | Ø1500~Ø8000 | ---- | Ø850×350 | 8~80 | 2×7.5 |

| | 630000 | Ø1500~Ø9000 | ---- | Ø900×380 | 6~60 | 2×11 |

Self-Alignment Welding Rotator

Welding cylindrical structures can be a challenging task due to their varying diameters. Our self-aligning welding rotators can make the process much easier and more efficient thanks to the incorporation of adjustable center distances, facilitated by either pre-set screw holes or lead screws, these welding devices ensure optimal alignment for a broad range of cylinder sizes, enhancing welding accuracy. This functionality allows for automatically adjusting the diameter of the cylinder being welded. Equipped with dual motors and cycloidal pinwheel or worm gear reducers, our welding rotators are suitable for a wide range of applications, from welding and polishing to lining and assembly of cylindrical tanks. Additionally, their design facilitates compatibility with specialized tooling for assembling and welding conical shapes and segmented bodies with different diameters.

Self-aligning welding rotators are widely used across various sectors, such as wind energy, pressure vessel manufacturing, petrochemical pipelines, steel constructions, boiler making, shipbuilding, and repair works.

| Model | Max. load carrying capacity (kg) | Suitable diameter of vessel (mm) | Wheel size (diameter × width) (mm) | Wheel speed (m/h) | Motor power (kW) | |

| Rubber rollers | Metal rollers | |||||

| | 5000 | Ø250- Ø2300 | Ø250×100 | 2×Ø240×20 | 6-60 | 0.75 |

| | 10000 | Ø320- Ø2800 | Ø300×120 | 2×Ø290×25 | 8-80 | 1.4 |

| | 20000 | Ø500- Ø3500 | Ø350×120 | 2×Ø340×30 | 6-80 | 1.5 |

| | 40000 | Ø600- Ø4200 | Ø400×120 | 2×Ø390×40 | 6-80 | 3 |

| | 60000 | Ø750- Ø4800 | Ø450×120 | 2×Ø440×50 | 6-60 | 4 |

| | 80000 | Ø850- Ø5000 | Ø500×120 | 2×Ø490×60 | 6-60 | 4 |

| | 100000 | Ø1000- Ø5500 | Ø500×120 | 2xØ490×70 | 6-60 | 5.5 |

| | 150000 | Ø1100- Ø6000 | ---- | Ø600×280 | 6-80 | 7.5 |

| | 250000 | Ø1200-Ø7000 | ---- | Ø700×300 | 8-80 | 2×5.5 |

| | 500000 | Ø1800- Ø8000 | ---- | Ø850×350 | 6-60 | 2*75 |