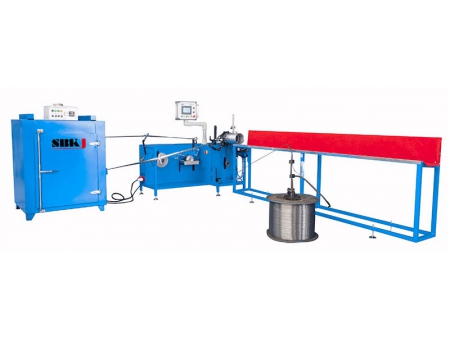

Aluminum Flexible Duct Machine

Request a Quote

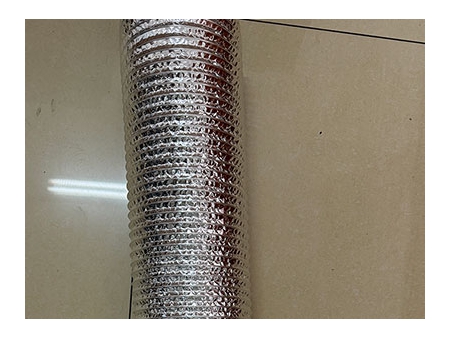

Developed independently by SBKJ, this innovative equipment is designed for manufacturing flexible aluminum ducts. The process involves using adhesives, aluminum foil, and steel wire, with the option to include materials such as non-woven fabric and PVC for enhanced duct properties.

Engineered to support the demands of modern buildings, these flexible ducts serve as important components in central air conditioning systems within high-rise structures and are equally effective in air purification setups and kitchen exhaust mechanisms. The production process efficiently stretches and spirals the aluminum, creating ducts that combine flexibility with durability for optimal airflow management.

Parameter| Diameter | 80-600mm |

| Material | Aluminum foil |

| Thickness | 0.02-0.08mm |

| Width | 30-60mm |

| Feeding speed | 70m/min |

| Cutting system | Automatic cutting |

| Power | Forming machine:1.5kW Oven:7.5kW Run-out table:1.5kW |

| Dimensions | Oven:1150x1050x1680mm Main machine:1860x950x1000mm Run-out table:2200x800x125mm Wire decoiler:670x680mm |

| Weight | 980kg |

| Voltage | 380V/3 phase/50Hz |