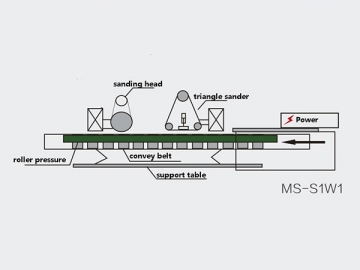

Edge Sander

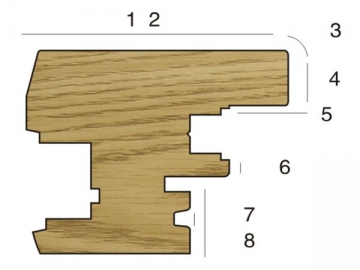

Furniture Sanding Machine / Cabinet Sanding Machine / Edge Sanding machine

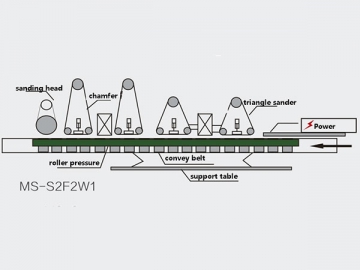

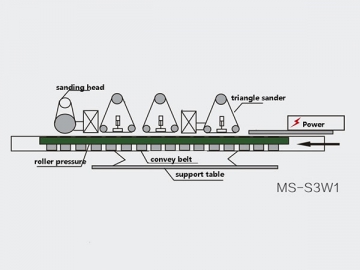

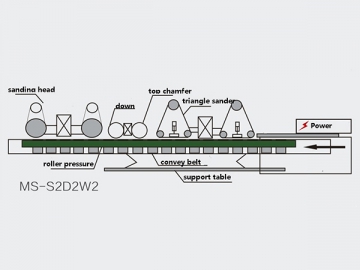

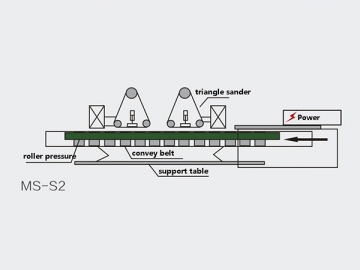

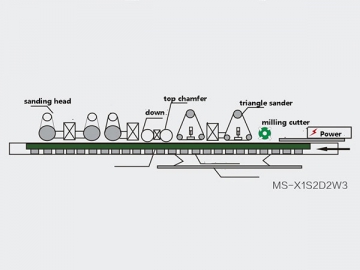

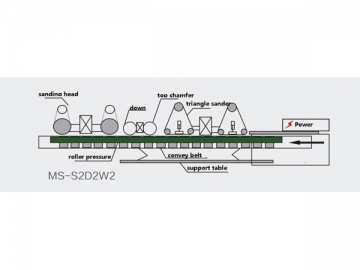

Machine Model: MS-S2D2W2 (machines are made according to specific customer requirements)-

Machine picture

Machine picture -

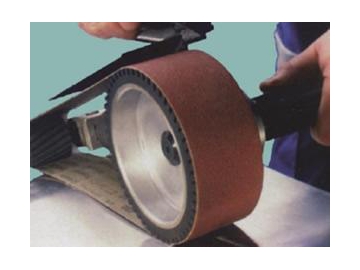

Installation of abrasive wheel on dual-purpose sanding head

Installation of abrasive wheel on dual-purpose sanding head -

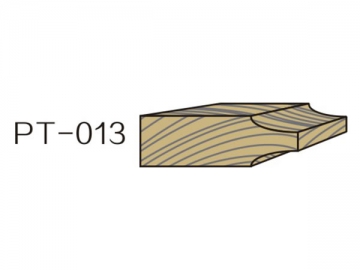

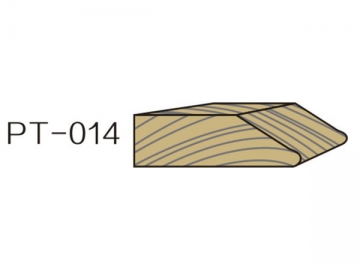

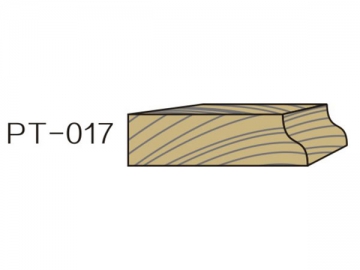

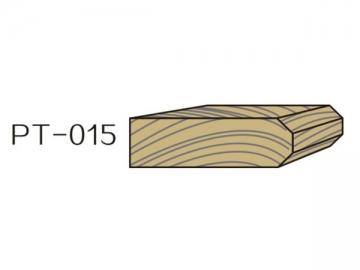

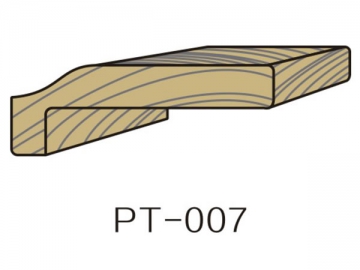

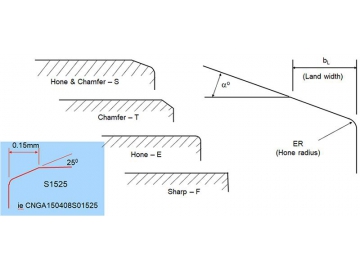

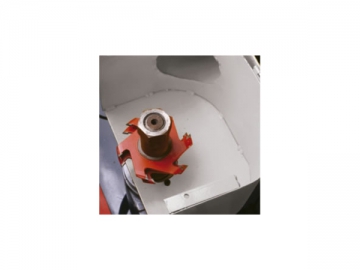

Chamfer cutter

Chamfer cutter -

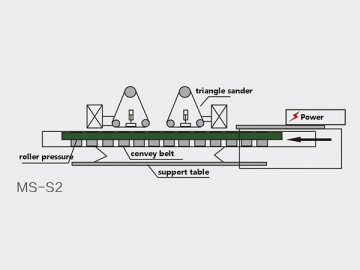

Material pressing by wheel

Material pressing by wheel -

Triangle sanding rack

Triangle sanding rack

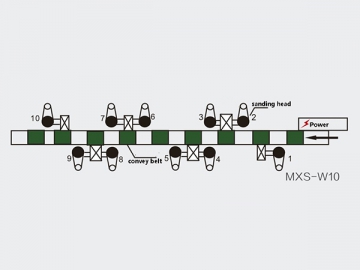

Applications

This edge sander is ideal for sanding edges on furniture, cupboards and bathroom boards. White body, wood veneer or lacquer sanding is acceptable for this machine.

Features

1. The triangle sander can be adjusted from -45° to 45°, making it suitable for profiling linear sanding.

2. The triangle sander features an oscillation device to ensure the workpiece surface is smooth and uniform. The sanding head is flexible and can be equipped with an optional oscillation device.

3. The sanding belt or spindle's speed is frequency controlled, making it ideal for sanding different wood product edges.

4. The pressing device uses a wheel press (users can choose a belt press) to ensure smooth transportation and no undue stress on the workpiece. The pressing device also protects the surface of the workpiece.

5. A chain conveyor features an adjustable speed, a cylindrical guide rail, a strong feeding power and a stable, reliable performance.

6. The pressure head on the triangle sander is easy to remove, making sanding head oscillation and compensation easy.

| Feeding width | 50-2000mm |

| Working thickness | 5-80mm |

| Feeding speed | 10-30m/min |

| Sanding belt size | 200mm*90mm |

| 880mm*90mm | |

| Tilting angle of sanding head | -90° |

| Sanding head motor power | 1.5kw |

| Triangle sander motor power | 2.2kw |

| Chamfer cutter motor power | 0.75kw |

Customers need to provide:

1. Information about the workpiece: product images, dimensions (maximum and minimum length, width and height), materials (MDF, wood, or other material) and a sample.

2. Parts to sand: sanding only the white body, or both the white body and paint.

3. Specific requirements

After receiving the aforementioned information, we will choose the right furniture and cabinet processing machine to meet your needs.

Device Options:

(S) 600 Type Triangle Sander | The triangle sander is suitable for flat sanding on the wood line, and the arc position can make shaped molding for sanding. In the sanding process the maximum sanding width is 80mm (users can choose up to 130mm). The length of the sanding belt is 2000mm, and auto oscillation avoids sanding belt deviation. The triangle sander's head automatically stretches out in order to prevent the workpiece from getting stuck. It's angle can be adjusted, making it suitable for sanding different curvatures on the workpiece. The sanding belt is controlled using a frequency, and its linear speed is 0-20m/min, making it suitable for sanding white body or primer on solid wood, MDF, gypsum, aluminum or other materials. |

| The sanding head is flexible, and users can install the sanding belt for flat sanding or shaped abrasives for profile sanding. The maximum sanding width is 80mm (users can choose 130mm), and the length of the sanding belt is 750mm. The angle can be adjusted, making it fit for sanding different curvatures on workpieces. The sanding belt is controlled by a frequency, and the linear speed is 0-20m/min, suitable for sanding white body or primers on solid wood, MDF, gypsum, aluminum or other materials. |

| It is suitable for sanding edge angles. The motor is 0.75kw. The triangle sanding head automatically stretches out and back, avoiding problems that arise if a workpiece gets stuck. The angle of the triangle sander can be adjusted, making it suitable to sand different curvatures and angles. The sanding belt is controlled by frequency, and the linear speed is 0-20m/min, making it suitable for sanding white body or primer of R angle of solid wood, MDF, gypsum, aluminum or other materials. The triangle sander features a high processing precision and stability, making it suitable for sanding under an R5 angle. |

| The chamfer cutter is applicable for making top and bottom R angles on a board edge. The motor is 0.75kw with a frequency revolution. The speed is stepless from 5000-12000r/min; and with a double-sided automatic tracking function, the chamfering edge of the workpiece can rotate 0-45°. This gives the chamfer cutter a high processing precision and stability, making it especially useful for R3 angles. |

| The profile milling cutter is suitable for molding white body boards and the standard motor is 2.2kw (though users can choose 3kw or 4kw) The revolution is frequency controlled and the speed is stepless from 5000-12000r/min. This gives the profile milling center a high processing precision and stability. With high procession precision and stability. |