Ultrasonic Sewing Machine JT-60

Request a Quote

Sewing, clothes sewing machine, industrial sewing machine

Ultrasonic Sewing Machine JT-60-S

Parameters

| Working Speed | 0-20m/min |

| Roller Width | 0-60mm |

| Power Supply | 220V/110V, 50/60Hz |

| Frequency | 20KHZ |

| Motor Quantity | 1/One motor |

| Lifting Method | Manual lifting |

| Net Weight | 100kg |

| Machine Dimensions | 120×54×110cm |

| Power | 1500-2000W |

| Certificate | CE |

Ultrasonic Sewing Machine JT-60-2S

Parameters

| Working Speed | 0-20m/min |

| Roller Width | 0-60mm |

| Power Supply | 220V/110V, 50/60Hz |

| Frequency | 20KHZ |

| Motor Quantity | 2/Two motors |

| Lifting Method | Manual lifting |

| Net Weight | 120kg |

| Machine Dimensions | 120×54×110cm |

| Power | 1500-2000W |

| Certificate | CE |

Ultrasonic Sewing Machine JT-60-2Q

Parameters

| Working Speed | 0-20m/min |

| Roller Width | 0-60mm |

| Power Supply | 220V/110V, 50/60Hz |

| Frequency | 20KHZ |

| Motor Quantity | 2/Two motors |

| Lifting Method | Pneumatic lifting with rotary welding horn |

| Net Weight | 120kg |

| Machine Dimensions | 120x54x118cm |

| Power | 1500-2000W |

| Certificate | CE |

Ultrasonic Sewing Machine JT-60-Q

Parameters

| Working Speed | 0-20m/min |

| Roller Width | 0-60mm |

| Power Supply | 220V/110V, 50/60Hz |

| Frequency | 20KHZ |

| Motor Quantity | 1/One motor |

| Lifting Method | Pneumatic lifting |

| Net Weight | 100kg |

| Machine Dimensions | 120x54x118cm |

| Power | 1500-2000W |

| Certificate | CE |

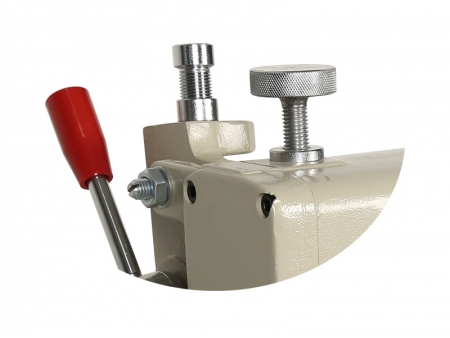

- Roller & Sample

Application

The JT-60-S ultrasonic sewing machine operates with a running speed that is four times that of ordinary sewing machines, yet it is still easy to operate with precision. It is designed for the production of lace garments, ribbons, handkerchiefs, tablecloths, curtains, bedspreads, pillowcases, quilts, tents, nonwoven shopping bags, nonwoven surgical gown, pp woven sack bags, and nonwoven fabrics.

Configuration

- Intelligent ultrasonic generator

- 20KHz ultrasonic transducer

- Single / double motor speed control system

- Manual (or pneumatic) pattern roller lifting system

Functions

- Side Trimming: the one side straight or curved cutting and side melting treatment can be carried out at the same time, making the side smooth, without coarse side.

- Melting: two layers or multi-layers can be melted together, no need for thread or needle. This process can replace sewing and the melting strength is excellent.

- Holes Breaking: holes with different patterns can be cut out and the treatment of side melting can be carried out.

- Material Cutting: materials can be cut into a single piece or multiple pieces at one time and the treatment of side melting can also be carried out. No coarse side will appear.

- Forming: the processes of cutting, melting and embossing can be carried out at the same time to form the product at one time.

Features

- The pattern rollers are diversified and can be designed according to customer needs.

- With super-strong power output, low and high two gear power adjustable, it is suitable for welding and cutting requirements of different materials and different thickness.

- Equipped with built-in computer chip and multi-channel ultrasonic protection system to ensure the safe and stable operation of the machine.

- The application of automatic frequency tracking system and ultrasonic soft-start technology guarantees this machine powerful performance.

Applicable Materials

Chemical fiber cloth, artificial leather, nonwoven fabric, gush glue cotton, thermoplastic film, chemical plastic slice etc.