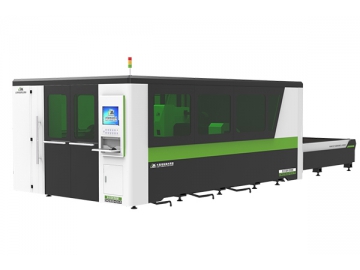

CMO1530-CH-A Enclosed Fiber Laser Cutter

| Model | CMO1530-CH-A | CMO2040-CH-A | CMO2560-CH-A |

| Working area (mm) | 1500×3000 | 2000×4000 | 2500×6000mm |

| Overall dimension(mm) | 8300×2900×2100 | 11000×3400×2100 | 13500×3900×2100 |

| Laser power (W) | 500-4000 | ||

| Max. working speed (m/min) | 100 | ||

| Positioning accuracy (mm) | ±0.03/1000 | ||

| Repeated positioning accuracy(um) | ±0.02/1000 | ||

| Power (kw) | 10 | 11 | |

| Weight (Kg) | 7000 | 8500 | 10000 |

| Power supply | Three phase 380V/50/60Hz | ||

| Working environment | Temp.: 0~ 45°C, Humidity≤80%, no condense water | ||

Samples:

- Metal signs laser cutting

- Metal cabinet laser cutting

- Metal screen laser cutting

- Carbon steel laser cutting

Product Feature

1.Gantry double rack and pinion, double servo motor drive system, MHMD with great torque and 1G acceleration can greatly enhance your production efficiency.

2.Intensive chassis is welded by high-strength square tube and iron sheet to achieve high precision and stability and effectively eliminate the shock in high-speed cutting.

3.Imported large gantry milling machine is processed through tempering treatment and vibration aging to eliminate stress and its geometric accuracy is within 0.03mm.

4.Crossbeam is made by drawn aluminum profile through finishing process, featuring light weight, high rigidity and high dynamic performance.

5.Professional laser cutting software can perform functions like graph nesting, sharp corner smoothing, high-speed laser perforation and fast cutting.

6.Integrated structure with compact machine layout and small footprint.

7.Germany IPG laser generator has high wall-plug efficiency of over 30%, greatly saving power energy and achieving the highest production efficiency.

8.Only the electric energy is needed for laser running to reduce running cost. High pressure air/N2/O2 can be blown to get a smooth cutting edge.

9.The laser cutter is equipped with EtherCat bus control system to deliver strong anti-interference ability, superior stability and high compatibility.