Corrugator Belt

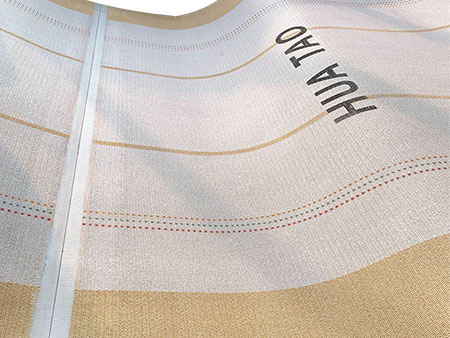

Corrugator belt with aramid edge is an upgraded version of proven woven high speed corrugator belt. It is ideal for corrugating machines with high production speed, even load systems and frequently changing paper widths.

Specifications of Features of corrugator belt with inwoven aramid kevlar edge| Model | HT-AE |

| Material | 100 % synthetic |

| Thickness | 9mm |

| Width Range | Max. 2880 mm |

| Length | 80 meters |

| Heat Resistance | 250℃(long time), 350℃(short time) |

| Tensile Strength | 15.1KN/40 mm |

| Coefficient of Friction | 0.42µ |

| Weight per Unit | (6.5±0.3)kg/㎡ |

| Air Permeability | 0.93×10m³×cm³/(c㎡·min·kpa) |

| Seam | Hot jaw lacing with flocking |

| Edge | 200mm or 400mm inwoven armoured aramid edges |

| Life Warranty | 70-80 million linear meters |

| Working Speed | Max. 400m/min |

- Corrugator belts with aramid edge suited to be used as top belt with high speed production (above 150 m/min);

- Superior resistance to tear and heat;

- Inwoven aramid edge helps to reinforce the belts, reduce wear substantially and ensure a long lifetime;

- This corrugator belt is particularly suitable for frequent changes of board width;

- Mostly used for all corrugating production lines;

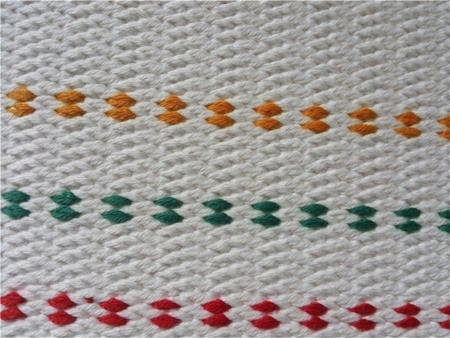

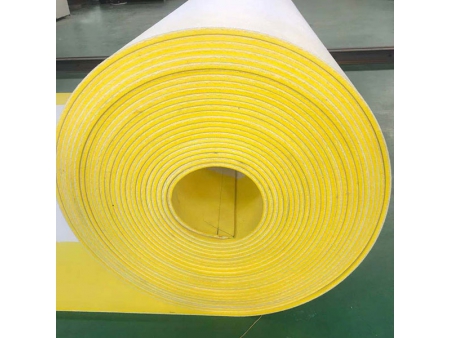

Woven corrugator belt with normal edge is woven by multilayer cotton yarn and chemical fiber by using weaving machinery, so it features superior water absorption, silent operation and wear resistance.

Specifications of woven corrugator belt with normal edge| Model | HT-N |

| Material | 100 % synthetic |

| Thickness | 8.5-9 mm |

| Width Range | Max. 2880 mm |

| Length | 80 meters |

| Heat Resistance | 200℃ |

| Tensile Strength | 15.1 KN/40 mm |

| Coefficient of Friction | 0.42µ |

| Weight per Unit | (6.5±0.3) kg/㎡ |

| Air Permeability | 0.93×10 m³×cm³/(c㎡·min·kpa) |

| Seam | Hot jaw lacing with flocking |

| Edge | Normal edge |

| Life Warranty | 60-70 million linear meters |

| Working Speed | Max. 400 m/min |

- Mainly used as bottom belt;

- Excellent tear resistance;

- High abrasive resistance;

- This corrugator belt has long lifetime;

- Great moisture absorption;

- Good heat resistance;

- Low noise emission;

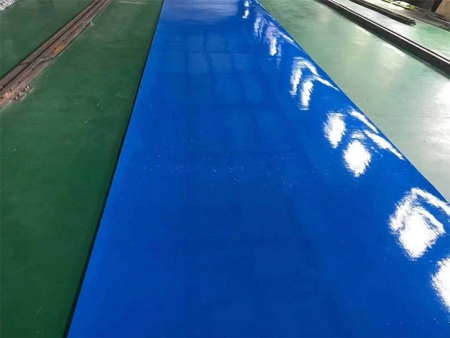

Silicon-coated corrugator belt is specially designed for applications requiring higher tensile strength and abrasive resistance. Its silicon coating can well prevent the slipping of coated paperboards, blank paperboards and thick paperboards during production.

Specifications of Silicon-coated Corrugator Belt| Product | High Speed Corrugator Belt |

| Thickness | 8mm, 9mm, 10mm |

| Width Range | 1400mm - 3200mm |

| Length | 80 meters |

| Heat Resistance | 240℃, the Krvalr edge up to 350℃ |

| Tensile Strength | 70Mpa |

| Coefficient of friction | ≥0.40µ |

| Weight per Unit | (7.5±0.3)kg/m2 |

| Seam | Hot jaw lacing / clipper with rubber coated |

| Edge | 100mm -400mm inwoven aramid edge reinforcement (kevlar) |

| Suitable Position | Top belt, bottom belt, upper belt, lower belt |

- Less slipping during operation;

- High cutting accuracy;

- Excellent abrasion resistant effect;

- Long service life;

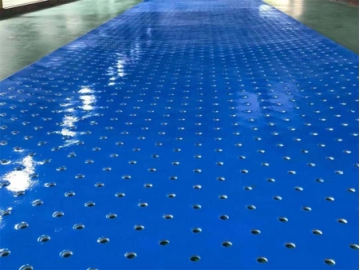

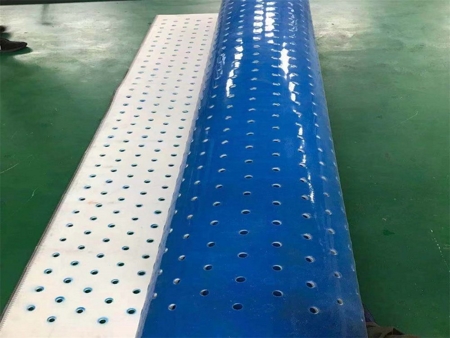

This perforated belt works with MarquipWardUnited cardboard making machine to cool down the temperature with patented thermal conductivity technology and vacuum technology, which will improve the quality of corrugated cardboard to be produced.

Features of Vacuum Belt / Perforated Belt- This perforated belt will protect cardboards from being crushed, thus enhancing their thickness and hardness.

- Holes on this conveyor belt will make the cardboards dehydrate swiftly, which makes the corrugated boards solidify quickly and hence leaves enough time for printing or loading.

- This vacuum perforated belt makes the cardboard look more flat while avoiding warp.

- No need to install an upper belt, no paper wrinkles caused by mismatch between upper and lower belt.

- Cardboards are fixed on the perforated belt, with position offset less than 1mm.

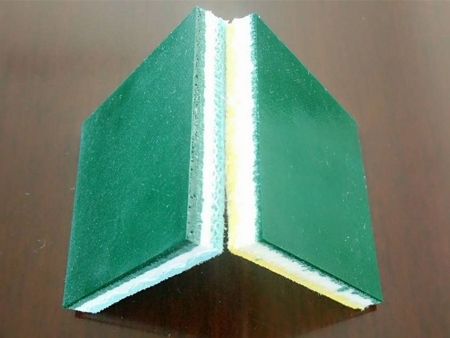

Needle punched corrugator belt is manufactured with advanced needle punching machine. This corrugator belt is made by top-grade PET fiber and NOMEX brand fiber, thus to ensure its good heat resistance and high strength. Besides, after thermoforming and chemical treatment, our needle punched corrugator belts possess stable dimension.

Specifications of Needle Punched Corrugator Belt| Product | Needle Punched Corrugator Belt |

| Thickness | 9±0.3 mm |

| Width Range | 1400 mm – 3200 mm |

| Heat Resistance | 200℃, Teflon edge 230℃ |

| Tensile Strength | 70 Mpa |

| Coefficient of Friction | ≥ 0.38µ |

| Weight | (5.5±0.3)kg/㎡ |

| Air Permeability | 4.7 m³/㎡ min |

| Seam | Concealed joint /American fasteners |

| Adjustable Rate(weft) | 0.8%/180℃ |

| Adjustable Rate(warp) | 0.42%/180℃ |

| Lifetime | 60-90 million meters (or 14000 working hours) |

- This corrugated belt is able to withstand high temperature;

- Highly aging resistant;

- Needle punched corrugator belt has even surface;

- The dimension is quite stable;

- Long lifespan;

- Customized needle punched corrugator belt is available;

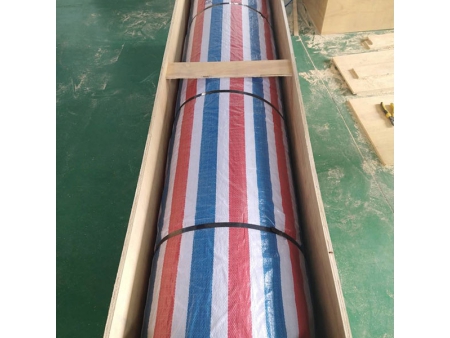

Traction belt, or take up belt, mainly conveys corrugated cardboard from single facer to corrugator bridge, or conveys paperboard during stacking.

Specifications of Traction Belt| Product | Take up belt/Traction belt |

| Material | 100% synthetic fiber |

| Thickness | 5-6 mm |

| Width Range | 600-2800 mm |

| Length | According to client’s request |

| Heat Resistance | Under 130℃ |

| Tensile Strength | 40 kpa |

| Main Winding Radius | R20 mm |

- The traction belt is particularly suitable for the lifting of heavy single-face corrugated boards;

- Huatao’s traction belt has a long lifespan;

- The smooth lifting of single-face corrugated cardboard is achieved;