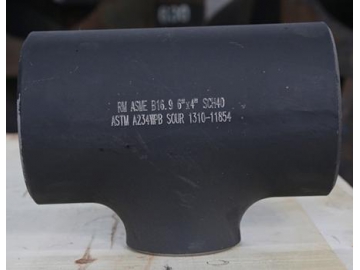

Carbon Steel Tee Pipe Fittings (Equal Tee, 45°Tee, Barred Tee)

- Carbon steel reducing tee

- Carbon steel equal tee

Carbon steel tee pipe fittings are usually applied to connect three lengths of pipes to redirect the fluid flow direction. More specifically, they are used for distributing or collecting the fluid from the run pipe. To fulfill different requirements from customers, our company provide tees with various diameters and shapes, such as T-shaped tee, lateral tee and Y-shaped tee, etc.

ApplicationsDespite of corrosion resistance not as good as stainless steel, carbon steel has many significant advantages, such as low cost, great processability and easiness of smelting. Hence, it has always been one of the most widely applied materials for manufacturing of pipe fittings used in various pipe systems.

Our carbon steel tee pipe fittings are mainly used for connection of pipes to convey oil and gas in power plants and industries of shipbuilding and petrochemical engineering.

Sample Exhibition 1. Seamless Carbon Steel Tee Pipe FittingsWith more than 35 years of experience in pipe fitting production and whole set moulds with all kinds of dimensions, we are fully capable of implementing hot extrusion process, which is the primary method for manufacturing carbon steel tee pipe fittings, to produce seamless carbon steel tee pipe fittings of various specifications, thus being able to satisfy the requirements of different customers.

- Hot forming carbon steel tee

Through steel plate compression-molding process, we are also able to produce carbon steel tee pipe fittings with large calibers, such as 100 inch(DN2500), based on customers’ specific needs.

- Butt welding reducing tee

Through mould forming process, we can manufacture the tailored fittings as per drawings, we can also manufacture carbon steel socket weld or threaded tee pipe fittings.

- Large size Y-shaped tee

- Y-shaped tee made by steel plate

- Steel barred tee

| Parameters | DN15-DN2500 (1/2"-100") |

| Wall thickness | Conventional wall thickness range: Sch 5s to Sch XXS Maximum wall thickness: 120mm |

| Standard | ASME B16.9, MSS-SP-75,DIN2616, DIN2617, JIS B2312, JIS B2313, DIN EN10253, GB/T12459, GB/T13401, GB/T25198,GB/T27684, SH3408, SH3409, GOST17378, etc. |