Vertical Form Fill Seal Machines for Powdery Products

- Packaging Lanes

- 1-2

- Dosing System

- Auger Filler

- Packaging Speed

- 20-80 Cuts/min/Lane

- Film Roll Width

- Up to 240mm

- Stick Pack Size (Length × Width)

- 50-180mm × 50-140mm

Film feeding system

Film feeding system Film loading system

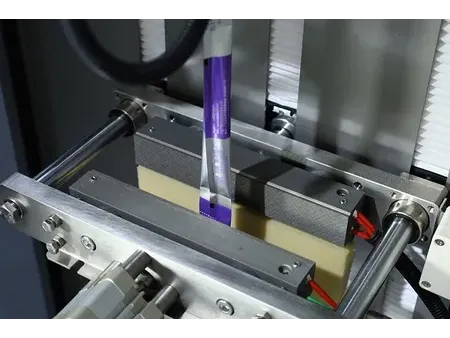

Film loading system Bag former

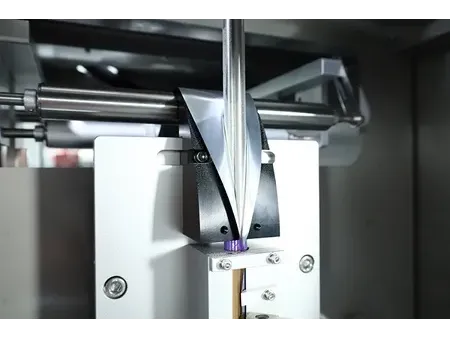

Bag former Cutting system

Cutting systemWidely applicable across the pharmaceutical, food, cosmetics, and health supplement industries, this machine is perfect for packaging a variety of products. Examples include medicinal granules, probiotics, protein powders, meal replacement powders, spirulina powder, instant coffee, lotus root powder, tea powder, pearl powder, and seasonings.

Your ideal solution for single-lane or dual-lane packaging of loose powder products in pharmaceutical-grade health supplements. This machine features a custom screw dosing system (auger filler) tailored to material parameters such as mesh size, flowability, and sugar content, ensuring precise and efficient filling.

With a maximum film width of 240mm, it produces powder bags ranging from 50-140mm in width and 50-180mm in length. The adjustable dosing system and rotary refill mechanism guarantee exceptional accuracy and speed. Operating at speeds of 20-80 cuts per minute, this equipment is designed for effortless maintenance, allowing all parts in contact with your materials to be quickly disassembled and reassembled. The 45° vertical sealing device ensures superior sealing quality and can be opened from the center for easier maintenance. Optimize your packaging process with this reliable and user-friendly machine. Contact us today to discuss how it can meet your specific needs!

Seal Type: Back Seal, 3 Side Seal, 4 Side Seal

| Model | |

| Number of Packaging Lanes | 1 |

| Dosing System | Auger Filler |

| Packaging Speed | 20-80 Cuts/min/Lane |

| Film Roll Width | Max.240mm |

| Inner Diameter of Film Roll | 75mm |

| Outer Diameter of Film Roll | Max.300mm |

| Stick Pack Width | 50-140mm |

| Stick Pack Length | 50-180mm |

| Seal Type | Back Seal, 3 Side Seal, 4 Side Seal |

| Cut Type | Round Cut, Straight Cut, Zigzag Cut |

| Power Supply | 220V, 1P, 50/60HZ, 5kW |

| Air Pressure (Consumption) | 0.6-0.8MPa (16-20L/min) |

| Machine Weight | Approx. 320kg |

| Film Thickness | 0.06-0.1 mm |

| Film Material | OPP/CPP, OPP/PE, BOPP/VMPET/PE etc. |

| Optional | Diaphragm Pump, Ribbon Coding Machine, Vacuum Feeder, Laser Marking Machine, Finished Product Conveyor, Magnetic Pump Filling Machine |

| Model | |

| Number of Packaging Lanes | 2 |

| Dosing System | Auger Filler |

| Packaging Speed | 20-80 Cuts/min/Lane |

| Film Roll Width | Max.240mm |

| Inner Diameter of Film Roll | 75mm |

| Outer Diameter of Film Roll | Max.300mm |

| Stick Pack Width | 50-140mm |

| Stick Pack Length | 50-180mm |

| Seal Type | Back Seal, 3 Side Seal, 4 Side Seal |

| Cut Type | Round Cut, Straight Cut, Zigzag Cut |

| Power Supply | 220V, 1P, 50/60HZ, 5kW |

| Air Pressure (Consumption) | 0.6-0.8MPa (16-20L/min) |

| Machine Weight | Approx. 320kg |

| Film Thickness | 0.06-0.1 mm |

| Film Material | OPP/CPP, OPP/PE, BOPP/VMPET/PE etc. |

| Optional | Diaphragm Pump, Ribbon Coding Machine, Vacuum Feeder, Laser Marking Machine, Finished Product Conveyor, Magnetic Pump Filling Machine |