Vertical Form Fill Seal Machines for Granular Products

- Packaging Lanes

- 1-2

- Dosing System

- Oscillating Cup Doser

- Packaging Speed

- 20-80 Cuts/min/Lane

- Film Roll Width

- Up to 240mm

- Stick Pack Size (Length × Width)

- 50-180mm × 50-140mm

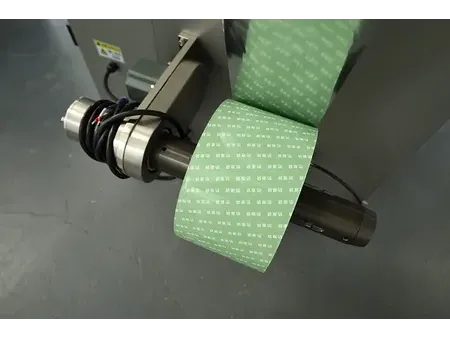

Film feeding system

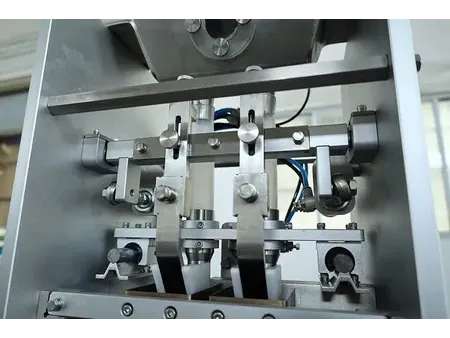

Film feeding system Volumetric cup dosing system (2 cups)

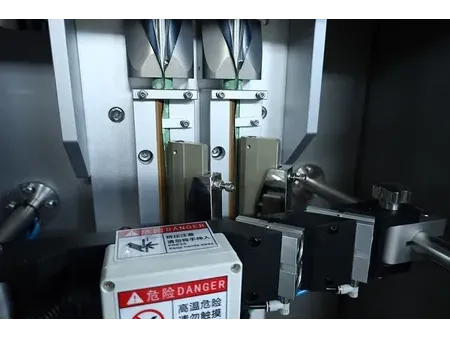

Volumetric cup dosing system (2 cups) Bag former

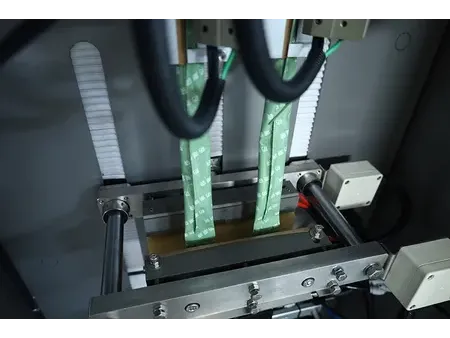

Bag former Horizontal sealing and cutting system

Horizontal sealing and cutting systemOur machine is incredibly versatile and widely applicable across industries such as cosmeceuticals, food, pharmaceuticals, and health supplements. It's perfect for packaging your products like sugar, pharmaceutical granules, coffee granules, and granular desiccants.

This machine is designed to meet your needs for single-lane or double-lane packaging of granules with consistent density. It features a precision oscillating cup doser, allowing you to independently adjust the dosing for each lane. The alternating feed-and-fill mechanism ensures your production achieves both accuracy and speed.

The contact parts, made from SUS316L stainless steel high-precision cups, deliver exceptional accuracy and efficiency, ensuring your products are handled with care. With a maximum film width of 240mm, this machine can produce packaging bags sized from 50–140mm in width and 50–180mm in length, with production speeds of up to 20–80 cycles per minute.

To simplify your operations, all parts in contact with your materials can be quickly disassembled and reassembled for easy cleaning and maintenance. The vertical 45° sealing device provides excellent sealing quality and features a middle-to-side opening mechanism, making it even easier for you to maintain. Reach out to us today to see how this machine can elevate your packaging efficiency and product quality!

Seal Type: Back Seal, 3 Side Seal, 4 Side Seal

| Model | |

| Number of Packaging Lanes | 1 |

| Dosing System | Oscillating Cup Doser |

| Packaging Speed | 20-80 Cuts/min/Lane |

| Film Roll Width | Max.240mm |

| Inner Diameter of Film Roll | 75mm |

| Outer Diameter of Film Roll | Max.300mm |

| Stick Pack Width | 50-140mm |

| Stick Pack Length | 50-180mm |

| Seal Type | Back Seal, 3 Side Seal, 4 Side Seal |

| Cut Type | Round Cut, Straight Cut, Zigzag Cut |

| Power Supply | 220V, 1P, 50/60HZ, 5kW |

| Air Pressure (Consumption) | 0.6-0.8MPa (16-20L/min) |

| Machine Weight | Approx. 320kg |

| Film Thickness | 0.06-0.1mm |

| Film Material | OPP/CPP, OPP/PE, BOPP/VMPET/PE etc. |

| Optional | Diaphragm Pump, Ribbon Coding Machine, Vacuum Feeder, Laser Marking Machine, Finished Product Conveyor, Magnetic Pump Filling Machine |

| Model | |

| Number of Packaging Lanes | 2 |

| Dosing System | Oscillating Cup Doser |

| Packaging Speed | 20-80 Cuts/min/Lane |

| Film Roll Width | Max.240mm |

| Inner Diameter of Film Roll | 75mm |

| Outer Diameter of Film Roll | Max.300mm |

| Stick Pack Width | 50-140mm |

| Stick Pack Length | 50-180mm |

| Seal Type | Back Seal, 3 Side Seal, 4 Side Seal |

| Cut Type | Round Cut, Straight Cut, Zigzag Cut |

| Power Supply | 220V, 1P, 50/60HZ, 5kW |

| Air Pressure (Consumption) | 0.6-0.8MPa (16-20L/min) |

| Machine Weight | Approx. 320kg |

| Film Thickness | 0.06-0.1mm |

| Film Material | OPP/CPP, OPP/PE, BOPP/VMPET/PE etc. |

| Optional | Diaphragm Pump, Ribbon Coding Machine, Vacuum Feeder, Laser Marking Machine, Finished Product Conveyor, Magnetic Pump Filling Machine |