Half Magnetic Drum

Permanent Magnetic Separator

Drum magnetic separator for removing iron particles from dry bulk materials

Half magnetic drums efficiently remove iron shavings, metal scraps, and iron blocks from large-volume dry materials. These separators are commonly used in mining, food processing, plastics, and recycling, helping to maintain clean materials and prevent metal contamination that could affect processing efficiency.

These permanent magnet separators are widely used for processing iron ore, grains, sand, gravel, plastics, wood, crushed glass, and industrial waste. The magnetic and non-magnetic zone distribution allows ferrous impurities to be automatically discharged, making them particularly useful in automated production lines. By continuously removing metal contaminants without manual intervention, half magnetic drums improve material handling and optimize separation efficiency.

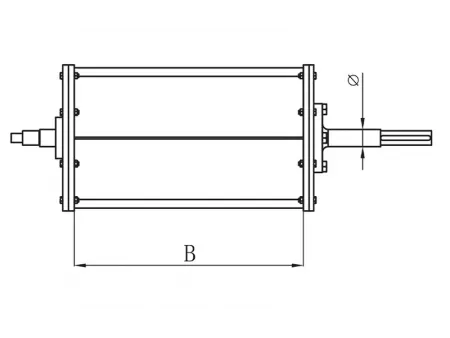

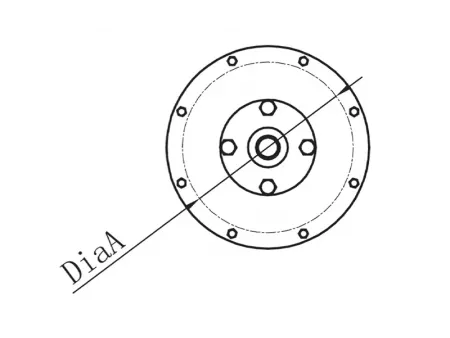

| Model | Dimensions (mm) | Weight (kg) | ||

| Dia. A | B | Ø | ||

| | 215 | 300 | 25 | 29 |

| | 215 | 350 | 25 | 34 |

| | 215 | 400 | 25 | 39 |

| | 215 | 450 | 25 | 44 |

| | 215 | 500 | 25 | 49 |

| | 215 | 600 | 25 | 59 |

| | 215 | 700 | 25 | 69 |

| | 215 | 800 | 25 | 79 |

| | 215 | 900 | 25 | 89 |

| | 215 | 1000 | 25 | 99 |

| | 315 | 300 | 25 | 62 |

| | 315 | 350 | 25 | 72 |

| | 315 | 400 | 25 | 82 |

| | 315 | 450 | 25 | 92 |

| | 315 | 500 | 25 | 102 |

| | 315 | 600 | 25 | 122 |

| | 315 | 700 | 25 | 142 |

| | 315 | 800 | 25 | 162 |

| | 315 | 900 | 25 | 182 |

| | 315 | 1000 | 28 | 202 |

| | 315 | 1100 | 28 | 222 |

| | 400 | 300 | 28 | 100 |

| | 400 | 350 | 28 | 116 |

| | 400 | 400 | 28 | 132 |

| | 400 | 450 | 28 | 148 |

| | 400 | 500 | 28 | 164 |

| | 400 | 600 | 28 | 180 |

| | 400 | 700 | 28 | 196 |

| | 400 | 800 | 35 | 212 |

| | 400 | 900 | 35 | 228 |

| | 400 | 1000 | 35 | 244 |

| | 400 | 1100 | 35 | 260 |

| | 400 | 1200 | 35 | 276 |

- Automatic separation design ensures that ferrous impurities are transferred to the non-magnetic zone and discharged without disrupting material flow.

- Constructed with 304 or 316L stainless steel, providing corrosion resistance and ensuring that materials remain free of contamination.

- Powered by permanent magnets, eliminating the need for external energy sources while maintaining consistent magnetic performance.

- Customizable magnetic field strength, allowing adjustments based on specific processing requirements and material types.